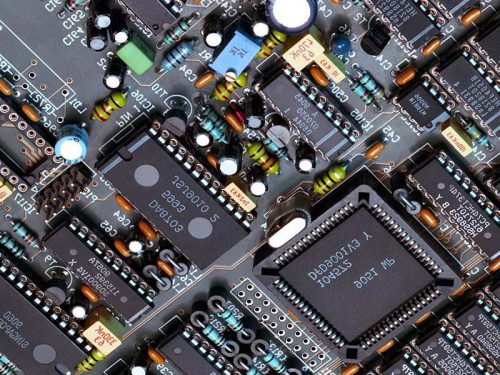

A PCB assembly may seem an easy process to you, but that is not true. The chip’s production is complex and requires extreme precision. This is why you should always rely on a professional PCB assembly manufacturer,like EASHUB for your 2-layer or 4-layer PCB assembly.

If you want to learn more about the 2-layer vs. 4-layer PCB assembly cost, say no more. This comprehensive guide will help you understand the pricing of this electronic component.

Top Things That Affect The 2-Layer Vs. 4-Layer PCB Assembly Cost

You must remember that the price of every PCB varies depending on different factors. Here are the top ones for your understanding:

-

Manufacturing Material

The material of every electronic item plays an integral role in its price. This is because the component determines the durability and functioning of the part. Typically, a PCB’s main part is FR4 lamination, which affects the compatibility of the chip.

However, you may require a combination of other materials if you want the PCB to suit your specific industry. For instance, you may need an additional component during assembly to improve the heat reliability of the circuit. This is essential if you will be using a board in a device that easily heats up.

-

Number Of Layers

A PCB can be made of one layer for low usage needs, or you can also increase the number. Of course, the price will also increase if you want a PCB with more than one layer. Typically, the average cost will show a 35% to 40% rise if you choose a 2-layer PCB assembly over 1-layer,click here to know more https://www.eashub.com/2-4-6-8-layer-pcb/

You will experience the same percentage increase in the cost if you shift from 2-layer to –layer PCB assembly. The primary reason behind the significant price rise is that the lamination process becomes more complex as the number of layers increases. More resources are also necessary.

-

Finishing

An essential action during the production of PCB assembly is the soldering of different parts. Many components are attached to the board with high precision using a soldering device. This enables placement by using heat and melting the finishing material.

Many finishing materials are present on the market and price differently. HASL, ENIG, and Elec Au are some of the top finishing components that allow excellent soldering. Of course, they also cost more than the other lower-quality finishing types. It is advisable to use a higher-priced component because it improves the PCB’s shelf life.

-

Board Thickness

You can choose thick or thin boards for your PCB assembly. The former costs more than the latter because it is made of more materials. Besides that, your overall PCB assembly cost will also increase due to the thickness. This is because more resources will be needed.

A thicker lamination will be required for assembling a thick PCB. This is also true if your making process is complex. This is why you should expect the 2-layer vs. 4-layer PCB assembly cost to increase because of thickness.

2-Layer Vs. 4-Layer PCB Assembly Cost

Once you consider all the cost factors, you can get a quote for your 2-layer or 4-layer PCB assembly cost. Typically, you will have to pay at least $33 for the former board. Remember, this is an average price and does not consider the custom specifications.

Meanwhile, you will have to pay at least $66 for a 4-layer PCB with the advanced circuit. The manufacturer will also determine the overall cost of your PCB assembly. So it is always best to get quotes from different brands before choosing one company.

Final Words

This is everything you need to know about the 2-layer vs. 4-layer PCB assembly cost. It is advisable to choose a board with the best materials and finishing for a high lifespan.

Interesting Related Article: “Using the assembly line technique to mass produce medicines“