Lasers have been used across many industries for many decades. The invention of the laser itself is commonly credited to the American physicist Gordon Gould who brought this technology to life in the late 1950s. Today, multiple industries rely on laser technology for marking purposes. Often, components or full products need to be marked with a permanent code or identification number on them as part of the manufacturing process. In the past, this may have been done with the use of chemicals, inks, or stamping other materials directly onto the product. However, laser technology has offered a cleaner and more reliable way to mark a wide range of materials and components. In this article, three key benefits of using a laser marker in an industrial setting will be discussed in detail.

Highly accurate and precise

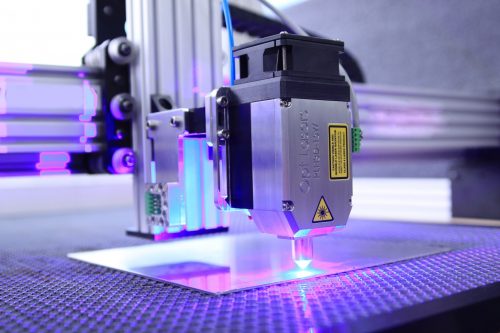

Laser marker technology offers the distinct benefit of being a highly accurate tool that can deliver uniform results on every marking task. Many industries will use an Ultraviolet laser marker such as those produced by Lotus Laser to ensure consistency and extreme accuracy for any marking requirements. Before such technology was available, some marking tasks would have needed to be completed by human workers. While human staff are competent at most complex tasks, they simply cannot work to the same level of precision and accuracy when extremely detailed or uniform jobs are required.

Conversely, a laser marking machine can produce identical results that are wholly free of error or variation every time. This allows the standardization of components and final products to an extremely consistent level. As such, laser marking machines are commonly used in industries that produce a high volume of products that need uniform identification or coding information to be marked on them.

Suitable for a range of materials

Another key benefit of using laser markers in industry businesses is that the user can choose from a range of materials as it works with a vast amount. These can vary from metals to specialist materials.

Common metal materials include:

- Copper

- Steel

- Nickel

Meanwhile, specialist material could include:

- Polycarbonate

- Types of foam

- Rubber

In fact, both natural and man-made materials are suitable for marking using laser marking machines. This means that such a piece of equipment can be used for various marking tasks and may even be moved to different parts of a factory when it is needed to complete other jobs or for different parts of the production process.

Can be linked to CAD systems

A final benefit of laser marking machines is that modern systems can be quickly and easily connected and integrated with computer-aided design (CAD) programs. A specific CAD platform will be used to design the marking or identification template. This can then be sent to the laser marking machine, which then produces the final design on the component or product. By being able to synchronise computer design programs with the marking equipment, it can mean that an almost limitless number of specific marking templates can be created. This can then mean that one laser marking machine can be used across other tasks and not just limited to one component or identification mark.

Interesting Related Article: “How To Care For A Laser Cutting Machine“