Scientists at EPFL’s Laboratory of Sustainable and Catalytic Processing (LPDC) have devised a new, cheaper method for atomic layer deposition (ALD).

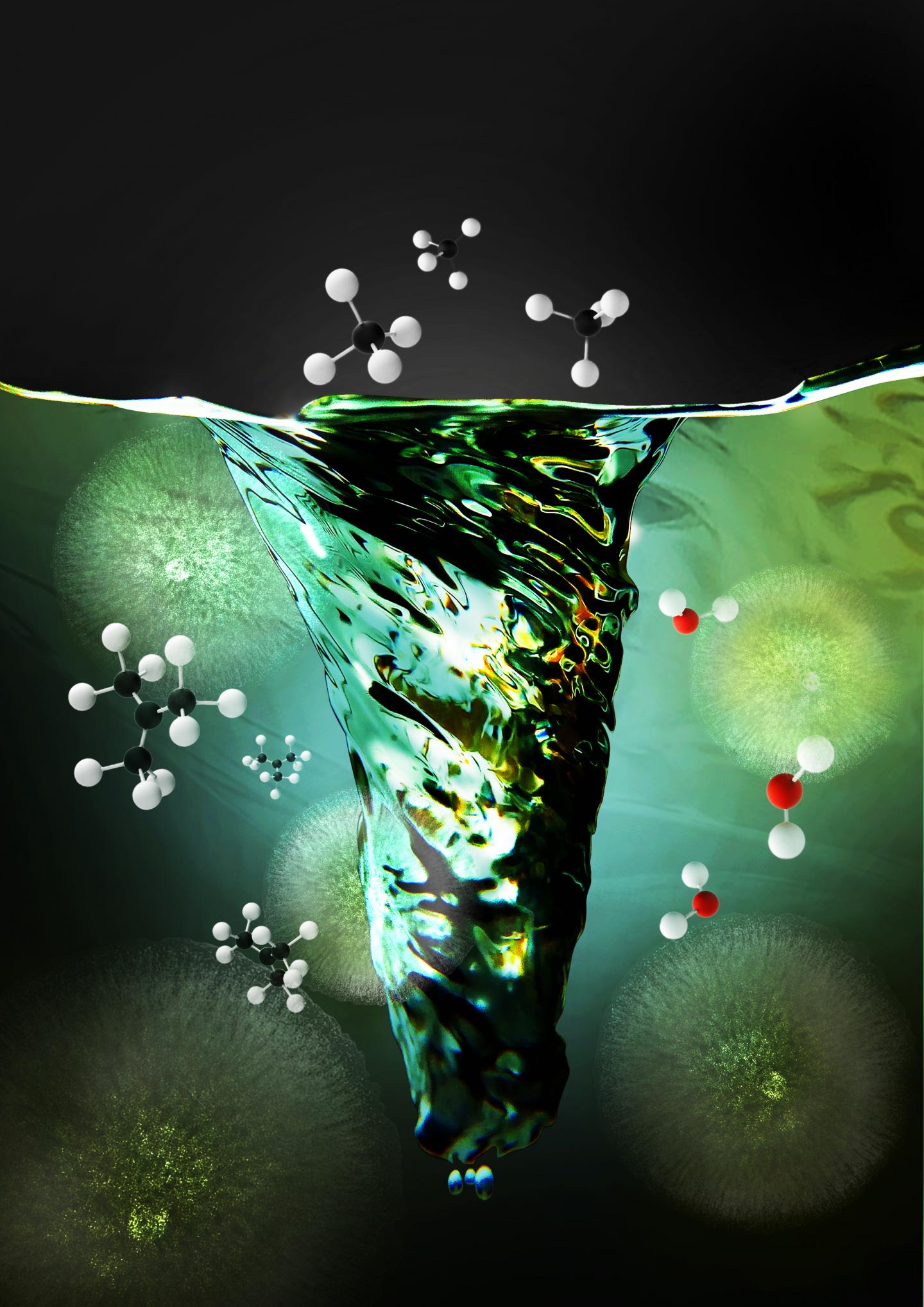

ALD is a well-established technique used in high-quality microelectronics. It involves depositing high-quality thin films one atomic layer at a time. The atoms come from a vaporized material called a precursor.

However, the technique is not without its limitations. Using ALD for depositing layers on large surface areas remains a challenge.

As the researchers explain in the abstract of the study,

“Its [ALD’s] industrial development has been largely confined to wafers and low‐surface‐area materials because deposition on high‐surface‐area materials and powders remains extremely challenging.

“Challenges with such materials include long deposition times, extensive purging cycles, and requirements for large excesses of precursors and expensive low‐pressure equipment.”

Professor Jeremy Luterbacher, head of EPFL’s Laboratory of Sustainable and Catalytic Processing said: “The sticking point is not necessarily making the right material but making it cheaply.”

“Coating larger surface areas with gas-phase methods requires long deposition times, and huge excesses of precursor, both of which increase costs,” added Benjamin Le Monnier, the Doctoral Assistant who conducted most of the research.

Greater precision is key

Using ALD in a liquid phase the researchers were able to produce materials indistinguishable from those made in the gas phase. This was achieved by carefully measuring the ratio of the reacting precursors before injecting them onto the surface of a substrate.

“Precisely measured precursor stoichiometries avoid any unwanted reactions in solution and ensure layer‐by‐layer growth with the same precision as gas‐phase ALD, without any excess precursor or purging required,” the abstract of the study explains.

The new technique is inexpensive as it only requires standard lab equipment. In addition, it can be easily scaled up to coat over 150 g of material using the same inexpensive laboratory glassware without any loss in coating quality.

“We believe that this technique could greatly democratize the use ALD on catalysts and other high surface area materials,” said Luterbacher.

Journal Citation

“Atomic Layer Deposition on Dispersed Materials in Liquid Phase by Stoichiometrically Limited Injections”

Benjamin P. Le Monnier, Frederick Wells, Farzaneh Talebkeikhah, Jeremy S. Luterbacher

Advanced Materials

First published: 11 November 2019

DOI: https://doi.org/10.1002/adma.201904276