The manufacturing industry is one that is forever changing, especially with the creation of new technologies and advanced machining. However, one of these processes has stood out from the rest, and that is CNC machining. In this article, we’ll explain how this innovative creation is taking over the world by storm. Sound interesting? Then keep on reading.

What is a CNC Machine?

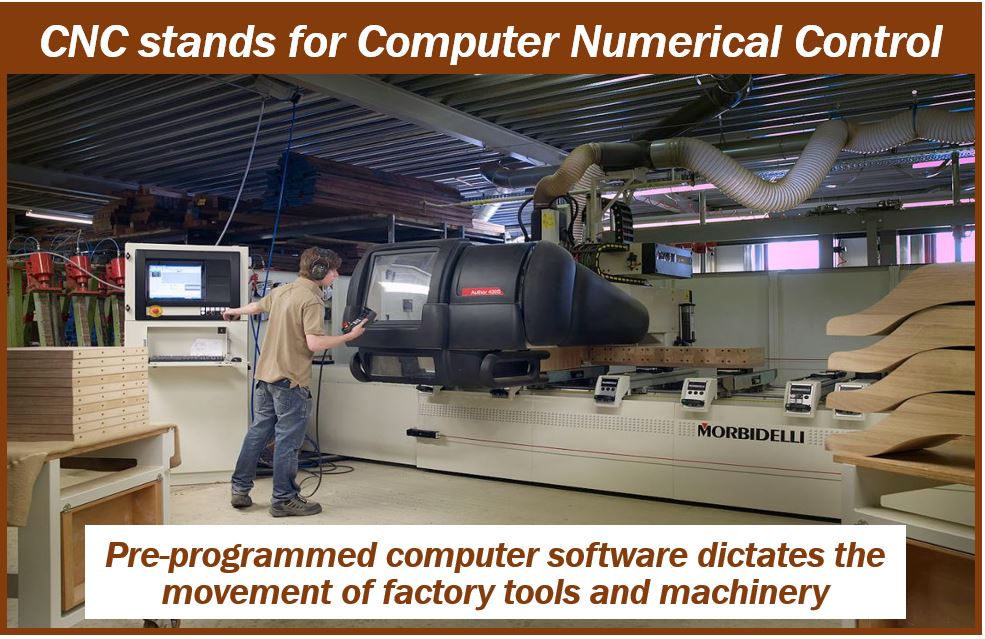

The role of CNC machines, also known as Computer Numerical Control Machines, is to manipulate and control other more traditional devices, by using computers. For example, drills, lathes, and millers can now be controlled externally, for greater precision. It really is a game-changer for the manufacturing industry and has become an increasingly popular tool.

What are some of the different types of CNC machining?

Plasma cutters: These are used to cut primarily two-dimensional shapes out of sheet metal.

Lathes: These are used to create spherical shapes by rotating the desired material in a spindle. A cutting tool then finalizes the required form.

Milling machines: This device uses cutters to shave, slice and cut pieces off the material. CNC milling machines can be programmed to get more precise cuts.

Drilling machines: CNC drilling means that holes can be placed faster and more efficiently. The different drill bits are mounted on a turret and can be changed via the computing system.

Grinders: These devices use a wheel to grind off the material until it forms the required shape.

How can it benefit a business?

There are many reasons why CNC machining can benefit a business, but the ultimate one is that it is very efficient. As computers will run your machines, you have the ability to produce higher quality products, in greater quantities. The number of manufacturing errors will be significantly reduced, meaning you will have less wastage and higher accuracy.

On top of this, CNC machining does not need to be turned off, so you can continue with your production unless maintenance is required. While humans can tire out, machines can keep going, and you’ll be able to achieve new goals every single day.

Why is it so important for the manufacturing industry?

As mentioned above, there are so many different benefits to this type of machining that it can only help improve the manufacturing industry. Businesses will be able to produce products in a much shorter amount of time, with fewer errors and higher quality. It really is a game-changer, and can potentially save the manufacturing industry hundreds and thousands of dollars.

Final thoughts

With the many benefits and great technology that CNC machining possesses, it’s no wonder why it is quickly taking over the manufacturing industry. It’s reliable, requires less maintenance, and can significantly improve a business’s profit. If you’re thinking of purchasing this type of machining, make sure you do your research so that you can find the best deal for your business. You certainly won’t regret it.

Interesting related article: “What is Manufacturing?”