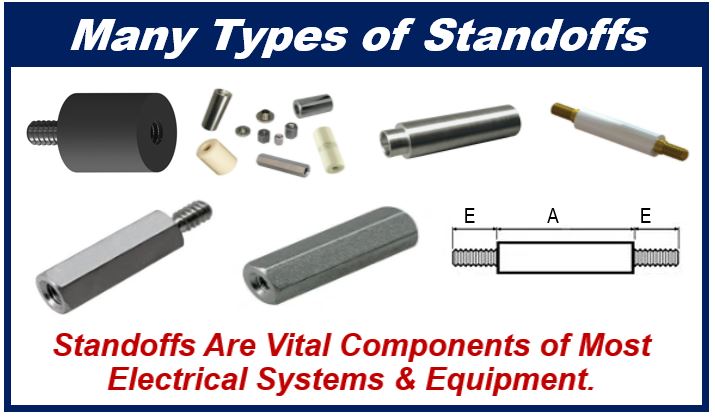

Standoffs are necessary components within most electrical systems and equipment. In addition to providing support, they are critical in keeping devices operational.. They act as insulators that prevent the unintentional flow of current between a conductor and the surrounding objects.

Extreme temperature standoffs are a category of standoffs specially designed for applications in harsh temperature conditions and have incredible strength.

Extreme Temperature Standoffs

Extreme temperature standoffs are primarily hex-shaped, but also come in other shapes. They are made from a high-performance plastic blend that gives them exceptional tensile strength. They can maintain pliability and properties in the most extreme conditions.

Extreme temperature standoffs have an operating range between -34 and 1850C. They come in varying lengths and in male-female and female-female varieties. These standoffs also come in varying thread sizes, making it easier to match the standoffs to various applications.

Applications of Extreme Temperature Standoffs

Extreme temperature standoffs are designed for cold or extremely hot conditions. They are commonly used in various applications, including:

Automotive

Technological advancements in the automotive industry have expanded the market for standoffs. Extreme temperature standoffs are commonly used in under the hood applications in computer and electrical components. They can withstand the intense temperature from the engine because of their unique material composition and design.

Aerospace

Standoffs used in the aerospace industry have to withstand both hot and cold temperatures. Extreme temperature standoffs are used in the engines and in mounting the cockpit systems. They not only have the capacity to withstand the extreme temperature but also reduced pressure and cold environment during flight.

Refrigeration

Extreme temperature standoffs perform just as well in cold as they do in hot applications. Consequently, they make an excellent choice for refrigeration applications, including domestic and commercial refrigeration.

How to Choose the Right Extreme Temperature Standoffs

For exceptional results, you need to consider other standoff specifications that could affect the performance of standoffs and the equipment they will be used in. Some of the specifications to consider include:

Shape

Extreme temperature standoffs are usually hex-shaped. But, you can also find them in other shapes depending on the requirements of the application. Hex-shapes are often preferred because of better weight distribution, and they are easier to fasten.

Outer Body Diameter

The outer body diameter is determined by the design and size of the device where the standoff will be used. When holding sizeable components like PCB boards, the outer body diameter is critical because it directly affects the weight-bearing capacity of the standoff.

Body Length

Body length is a vital consideration for various reasons. The right length depends on the distance you want to place between the components and the body. The right length also depends on the design of the equipment. Extreme temperature standoffs come in various lengths. As such, finding the ideal length for the application in question shouldn’t be hard.

Thread Size

Standoffs come in three primary thread sizes 4-40, 6-32, and 8-32. Each thread size offers a different strength of the connection. Choosing the right thread size ensures you get maximum connection depending on the application.

Interesting related article: “What is a Device?“