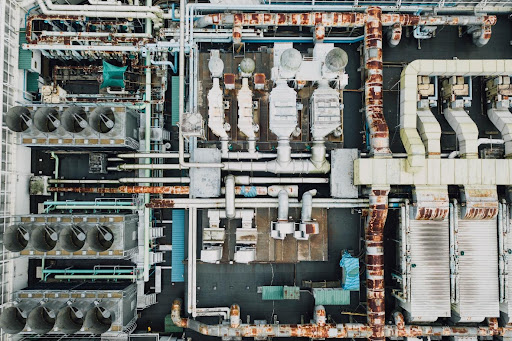

Today we’re gonna see what a Venturi Scrubber is, what it’s used for and what is its purpose.

In industrial plants, the most widely used dedusting systems are self-cleaning bag filters.

However, there are cases in which this option is not feasible, for example when the powder to be treated is not dry, or when the gas to be treated has sharp temperature changes or, again, when it’s very humid; so this is where the Venturi Wet Scrubber comes into play.

Let’s now see all the details with the Sorgato.com team, experts in Water Filter Scrubber and other technology adopted for fluids, dust and gas.

What is the Venturi Scrubber?

The Venturi Scrubber is a device used for air purification, which operates by removing the largest particles from various gaseous substances, exploiting the mechanics of fluids and their chemical-physical properties.

It can be made of plastic material or AISI 304 steel sheet, and it consists of 3 sections: a converging part, a groove and a diverging part.

The filter can be built with different configurations, depending on the types of pollutants to be treated, the quantities and the needs of the industry for which it is intended.

The Venturi Scrubber design, the cost of the plant and its operation are crucial elements to take into consideration when planning.

It’s used to remove minerals, dust and vapors from industrial, corrosive and hazardous fumes, exhaust gasses and other volatile substances released during manufacturing processes.

Thanks to the versatility of its technology, it is used in the abatement of particulates that come from emissions from chemical industries, wood industries and many others.

The areas of intervention of this machine cover various sectors, including the following:

- food;

- textile;

- chemical and pharmaceutical;

- cosmetic;

- steel mills;

- nautical;

- ceramic industry;

- waste treatment, and more.

Now let’s move on to how it works…

Venturi Scrubber operation: how does it work?

The Venturi Scrubber is a chemical-physical system that combines the action of a chemical reagent with an increase in the speed of the air entering the system.

The Venturi Scrubber technology consists in forcing the gas to be cleaned through the converging section and throat, in order to make the gas collide with the scrubbing water and so as to incorporate the dust, so that it is separated from the flow.

The high speeds and the amount of water being sprayed create a whirlwind of interactions that promote separation.

The washing liquid is injected into the filter upstream of the throat or directly into the section, to be atomized by the turbulence created in the throat, enhancing the liquid – gas contact.

Separation then takes place in the diverging part of the filter, where due to the reduction in speed (and consequently energy) of the flows, the dust particles separate from the effluent, after passing through the appropriate demister.

What are the advantages of the Venturi Wet Scrubber?

Its advantages include:

- high purification efficiency > 99%, even with polluting particles with a diameter equal to or greater than 1 micron.

- Ease of management and use, in the regulation and control of the various parameters.

- Reduced maintenance costs.

- A highly efficient treatment of odors and pollutants, especially when combined with a fixed bed or floating bed scrubber.

- Guaranteed safety for fire and explosion; in fact, the Venturi Wet Scrubber does not require any protection device, with a consequent reduction in costs.

One way to improve the Venturi Scrubber is to install a lining inside the chamber, such as a fiber material, which reduces leakage and turbulence.

It is also possible to increase the speed of the flow inside the chamber, in order to increase the efficiency of the scrubber.

Additionally, by installing multiple sections or sprayers, contact between the scrubbing solution and contaminants can be maximized.

This type of filter is generally more expensive than the classic and cyclonic spray scrubbers but, on the other hand, they have a higher capture efficiency for especially fine dust.

You may be interested in: Why Hiring A Cleaning Service Is A Good Idea