What is failure analysis? Definition and examples

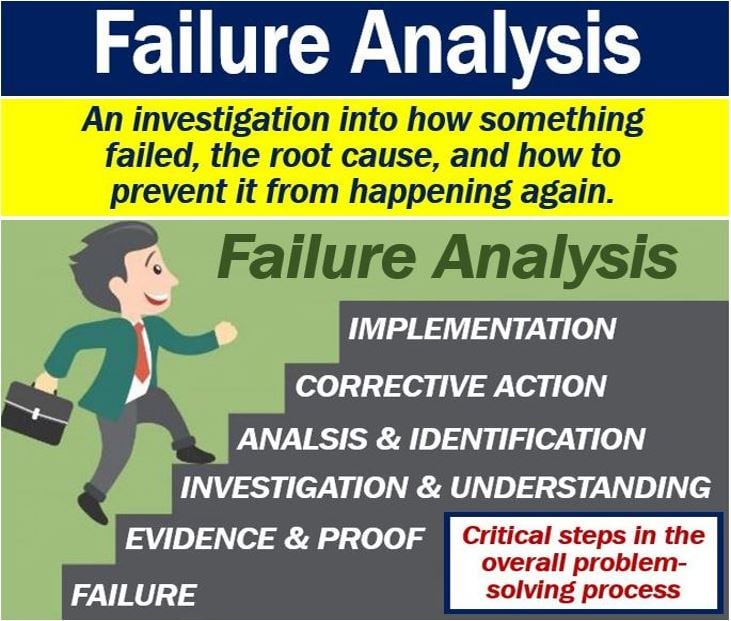

Failure analysis involves investigating how something failed, why it failed, and how to prevent it from happening again. It is a systematic and logical examination of a machine or equipment. Investigators also examine all relevant documentation. Sometimes the analysis also includes determining liability.

Liability, in this context, refers to the company’s responsibility. For example, if the company is to blame for the failure, will it have to pay compensation or a fine?

The investigators’ objective is to detect and analyze the causes and consequences of a failure. Their goal is also to determine what corrective actions are necessary. The corrective actions help prevent a repetition of the failure.

FMEA

One of the first highly structured systematic techniques for failure analysis was FMEA. FMEA stands for Failure Mode and Effects Analysis.

Failure mode refers to the manner in which failure occurs, i.e., how something failed or could potentially fail.

Failure analysis – product development

All processes and products have modes of failure. By analyzing past and potential failures, designers can understand their impact and improve their designs accordingly.

In product development, for example, failure analysis helps prevent malfunctions and ensures product life. It also prevents safety hazards.

According to ASM International, the world’s largest materials information society:

“Analyzing failures is a critical process in determining the physical root causes of problems.”

“The process is complex, draws upon many different technical disciplines, and uses a variety of observation, inspection, and laboratory techniques.”

Element.com suggests three reasons to perform a failure analysis: 1. To determine the root cause of the failure. 2. To prevent similar product failures from happening again. 3. To improve future products.

Failure analysis – a discipline

Investigators who carry out effective failure analyses can save money, lives, and resources.

In many branches of manufacturing, such as the electronics and hi-tech industries, it is an important discipline. Regarding failure analysis in the electronics industry, Wikipedia writes:

“It is a vital tool used in the development of new products and for the improvement of existing products.”

“The failure analysis process relies on collecting failed components for subsequent examination of the cause or causes of failure using a wide array of methods, especially microscopy and spectroscopy.”

Root cause failure analysis

When something, such as a machine, for example, fails, it is important to know why. Root cause failure analysis helps companies determine what the source of a product’s failure was.

It provides whoever created the product with data that can help determine how to address the problem. The analysis also helps determine what to do to prevent future failures.

Root cause failure analysis is typically a multidisciplinary process. An analysis may include visual inspections, simulation tests, and chemical analysis. It may also involve environmental and metallographic tests.

What tests the investigators utilize depend on what went wrong and the type of product.

NTS.com writes:

“Root cause failure examinations are designed to determine the cause of the failure and the corrective actions needed to prevent it.”

“However, product failure can be a complicated process. In our experience, device failure is rarely due to a single event.”