Optimum capacity – definition and meaning

Optimum capacity is a manufacturing rate with the lowest possible cost. When a company is at optimum capacity, it produces the most it can with the smallest amount of cost. In other words, a production capacity in which the cost of production of one extra unit is the same as the average cost for every unit.

Put simply, you reach optimum capacity when the cost to produce each unit cannot be any cheaper.

We use the term not only for goods but also for services.

According to The Law Dictionary, optimum capacity is:

“[A] situation in which a company is producing a high quantity of goods at the lowest possible cost per unit.”

The word ‘optimum’ means ‘the best’, or ‘the most likely to bring success.’

According to the Online Etymology Dictionary, ‘optimum’ appeared in the English language in 1879. It is a Latin word that means ‘best.’ We used the term initially in biology. However, it then spread into many other fields, including economics and business.

The term ‘optimization‘ refers to trying to get the maximum production at the lowest possible cost. The verb is to ‘optimize.’

Maximum capacity vs. optimum capacity

When we try to maximize capacity, it means we try to produce as much as possible. In that sense, it is similar to trying to optimize capacity. However, maximum capacity disregards costs.

Optimum capacity is a combination of maximum capacity and minimal costs.

Put simply; optimum and maximum capacity are similar. However, ‘maximum’ does not take into account costs, while ‘optimum’ does.

Optimum capacity – example

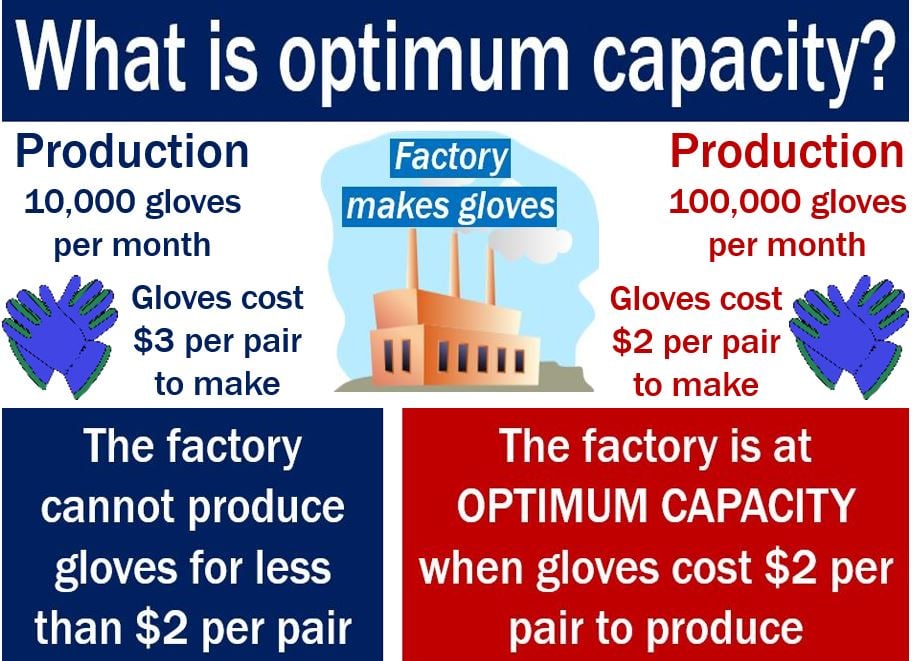

Let’s suppose you have a factory that makes gloves. It can produce gloves at $3 per pair if it turns out 10,000 pairs per month.

However, if it operates at 100,000 pairs per month, it can produce them at $2 per pair. After that, no matter how high its production is, it cannot make them cheaper.

The optimum capacity of your glove factory is, therefore, when it makes them at $2 per pair.

Phrases with ‘Optimum’

There are many two-word phrases we can make with the word Optimum. Here are some of them:

-

Optimum Performance

The highest level of functioning or efficiency that a system, machine, or person can achieve.

-

Optimum Conditions

The most favorable conditions for a specific process or activity to occur.

-

Optimum Temperature

The ideal temperature at which a process, like a chemical reaction or an enzyme activity, works best. We could also use it for an event, as in: “The optimum temperature for a human to work in is 23C (or 73.4F).”

-

Optimum Health

The state of peak physical and mental well-being.

-

Optimum Level

The level which is considered to be the best possible under specific circumstances.

-

Optimum Growth

The most favorable rate or condition for growth, whether in economics, biology, or personal development.

-

Optimum Range

The best or most effective range of values or conditions.

-

Optimum Quality

The highest standard of quality achievable under given circumstances.

-

Optimum Balance

The perfect state of equilibrium or proportion in a particular situation.

-

Optimum Utilization

The most efficient use of resources or capacity.

-

Optimum Yield

The maximum amount of product that can be obtained from a process or cultivation. We use this term in science, business, and farming.

-

Optimum Output

The greatest quantity of work or results that a system or person can produce.

-

Optimum Capacity

The best possible holding or performance capability of a system or facility. As in: “That stadium’s optimum capacity is 80,000.”

-

Optimum Strategy

The most effective plan or approach to achieve a goal.

-

Optimum Efficiency

The state of achieving the maximum productivity with minimum wasted effort or expense.

Other languages

Here is a list of translations of the word Optimum in the world’s most widely spoken languages:

- óptimo (Spanish)

- optimum (French)

- ottimale (Italian)

- optimal (German)

- optimal (Swedish)

- 最佳 (zuìjiā) (Chinese – Mandarin)

- इष्टतम (iṣṭatama) (Hindi)

- أفضل (afḍal) (Arabic)

- оптимальный (optimal’nyy) (Russian)

- en iyi (Turkish)

- 최적 (choejeok) (Korean)

- tối ưu (Vietnamese)

- 最適 (saiteki) (Japanese)

- optimal (Javanese) Nearest equivalent.

- terbaik (Malay/Indonesian)

- оптимален (optimalen) (Bengali)

- ótimas (Telugu) Nearest equivalent./li>

- उत्तम (uttam) (Marathi)

- óptimo (Punjabi) Nearest equivalent.

Video – What is Optimum Capacity

From Marketing Business Network, our sister channel in YouTube.