3D printing has already revolutionised the manufacturing industry outshining rival techniques like CNC machining. But, this technology is still likely to bring about new opportunities that will affect many industries including medicine, dentistry, art and entertainment, toys and manufacturing. Below are some of the most interesting new developments brought about by this advanced tech and what we can expect from the future of 3D printing.

3D printing has already revolutionised the manufacturing industry outshining rival techniques like CNC machining. But, this technology is still likely to bring about new opportunities that will affect many industries including medicine, dentistry, art and entertainment, toys and manufacturing. Below are some of the most interesting new developments brought about by this advanced tech and what we can expect from the future of 3D printing.

Smartphone 3D Printing

Did you know it is now possible to 3D print your own designs using a smartphone? The ONO Smartphone 3D Printer has made some startling things possible for those with a smartphone and a spare $100 dollars for the external 3D printer. Using your phone’s light, an app, and the printer, you can design and print in just minutes. This process is possible thanks to the plastic filament that can be easily cured into a solid-state. With all this on offer, and the ability to send printable designs to anyone, we can imagine a world where people use these printers in a way akin to the holograms in Star Wars.

3D Printing 3D Printers

This may sound like something from a science fiction movie, but 3D printing has already progressed to the point where some printers can create duplicates of themselves. For anyone familiar with stories of robots taking over the world, the idea of these computers replicating themselves would inspire an addition to Isaac Asimov’s Three Laws of Robotics. However, at the moment, 3D printers will only manufacture their own parts which will have to be assembled by a human.

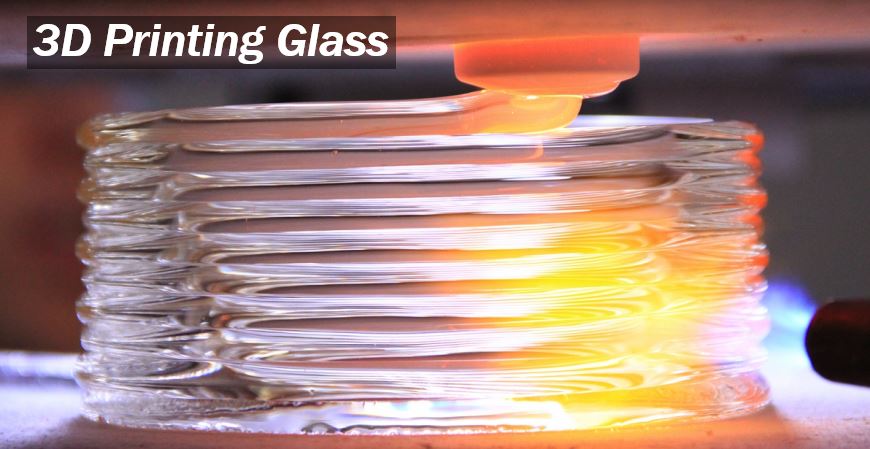

3D Printing Glass

Glass is a tricky material to use and, although the technology is by no means commercially ready, it is now possible to 3D print glass designs. Currently, there are two ways to print in glass: one uses molten glass, which requires a lot of heat, and the other uses ground glass powder. Both are capable of producing complex objects; however, at the moment these objects are a little delicate and prone to breaking. In the future, we are likely to see this improve so the material can be more easily utilized by artists and manufacturers alike.

Glass is a tricky material to use and, although the technology is by no means commercially ready, it is now possible to 3D print glass designs. Currently, there are two ways to print in glass: one uses molten glass, which requires a lot of heat, and the other uses ground glass powder. Both are capable of producing complex objects; however, at the moment these objects are a little delicate and prone to breaking. In the future, we are likely to see this improve so the material can be more easily utilized by artists and manufacturers alike.

Binder Jet Printing

Binder Jetting is one of the advanced 3D printing techniques that HP says can allow printers to operate fifty times faster than any others available on the market. This new process uses powdered metals laid down onto the printer bed, dropped carefully into a position where they stick like glue. Speeding up the process in this way will create further efficiencies for many industries that rely on speedy printing of custom designs and rapid manufacturing of metal parts which is harder to get right than plastic.

Although 3D printing is already revolutionizing many businesses, thanks to processes like rapid prototyping, there is still a lot of scope for improvement. Plus, as the tech improves the process is creating less waste, reducing the carbon footprint in transportation, increasing manufacturing times and allowing for easier customisation. All this makes 3D printing technology the one to watch in 2020.