Due to the rapid technological advancements in the past few decades, things that were mere sci-fi concepts are now at our fingertips. One of the biggest and most important trends in many industries is automation. When it comes to warehousing and intralogistics, one of the best and easily applicable solutions are robots, especially AMRs. What are these, and how can they improve your warehouse operations? Learn about it below!

What is an AMR?

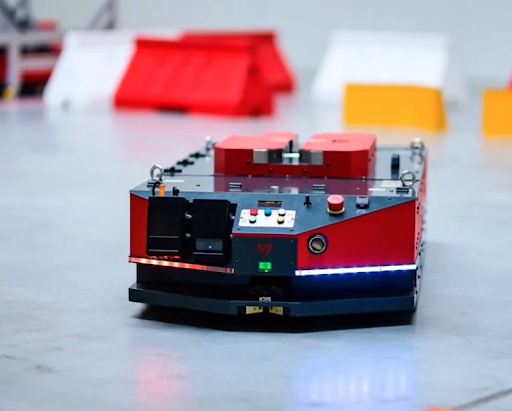

AMR stands for Autonomous Mobile Robot, which is a type of self-driving trolley that can perform various transport tasks across production plants and warehouses without any external interference. Depending on their type, they can replace anything from sack trucks to forklifts made for heavy loads. Autonomous Mobile Robots can be roughly divided into two groups – specifically designed for a given task or flexible machines that can be fitted with various interchangeable modules.

You can learn more about Autonomous Mobile Robots at https://versabox.eu/what-is-an-amr-robot/.

AGVs vs AMRs – what’s the difference?

AGVs (or Automated Guided Vehicles) are a type of unmanned trolleys etc., whose movements are restricted by specially designed paths. They can perform routine tasks in many types of facilities. The first AGVs were created in the mid-twentieth century. This type of vehicle can be guided via 2 types of navigation:

- Inductive navigation – robots move along a magnetic field generated by a special current-conducting cable embedded in the floor. Adapting this solution to already existing facilities is a costly and troublesome endeavour, as placing these cables or changing their route requires extensive construction work. Fortunately, this technology is being replaced by more flexible options;

- Ferromagnetic/reflective navigation – it’s a more modern way of guiding automated trolleys. In this method, a sticky magnetic/reflective (the second one requires robots with visual sensors) is used to mark robots’ routes on the floor. It’s by far cheaper and easier to implement than the classic electric cables.

On the other hand we have Autonomous Mobile Robots (AMRs) which are fully independent – they can choose optimal routes between pick-up and delivery points thanks to advanced visual navigation. AMRs are equipped with machine vision technology and laser sensors, thanks to which all they need to start working in a given space is a manually controlled first drive through it. Thanks to a dedicated mode, the robot will create a virtual map, which it will use to navigate itself, easily avoiding collisions with permanent obstacles and other moving objects or personnel. This map can be easily adjusted, modified, and used to change objectives on the fly. An AMR is ready to work in mere hours after being taken out of the box.

This relatively new technology means that AMRs are fully worthy of being called cobots/collaborative robots – they are completely safe to use around people and don’t have to be separated from humans or other machines. They are also equipped with passive safety measures, such as brightly coloured bodies, sound/light warning systems etc. All this makes them by far the safest way to conduct internal logistics.

If you’re looking for high quality, modular AMRs that can be fully integrated with a WMS (Warehouse Management System), take a look at the offers at https://versabox.eu/.

Advantages of using AMR trolleys

An AMR is far more than just an automated sack truck – it can carry out various transportation processes, have high load capacity and can be easily matched with other solutions such as conveyor belts or automated storage units. In practice, AMRs can replace almost any means of transportation for raw material, intermediates, and complete goods in every aspect of production, storage, and shipping.

Their warehouse optimization capabilities come from a wide range of advantages, such as:

Maintenance-free operation

The implementation of AMRs is a great way to lower work cost – due to operator-less function, a single robot can easily replace three work shifts. Two trolleys can operate continuously, as they can replace each other during visits to a charging station (a full battery allows for about 8 hours of work). Plus, they always work at the same pace, don’t get distracted nor tired, and can perform monotonous tasks without negative effects.

Scalability

AMRs can be easily fitted into practically any transport system, allowing flexible adaptation to changing working conditions. You won’t have to change anything in your warehouses’ infrastructures – these robot trolleys can fit into any facility, no matter its size. Moreover, you don’t have to invest in a whole robot fleet at once – AMRs can be implemented gradually and even one of them can provide a serious boost in efficiency.

Reliability

At their core, AMRs are simple machines with easily replaceable modular build. This makes them more reliable than logistic trains or forklifts and contributes to lowering their failure rate. Plus, when a module gets damaged, you simply replace it in just a few moments. Thanks to this, you can benefit from reliable schedules and achieve way higher productivity.

Versatility

Thanks to various tools and accessories provided by their work modules, AMRs can be used for, among others, lifting pallets/containers, towing warehouse dollies and other trolleys, transporting hanger frames or cooperating with roller conveyors.

Filling in staff shortages

There’s no denying that lately there’s a shortage of blue-collar workers in many industries. The implementation of AMRs can protect you from critical lack of able employees and greatly reduce the probability of costly downtimes/delays.

Far lower accident rate

The only time an AMR could be involved in a collision, it would come from human error. Thus, replacing, for example, human operated forklifts with AMRs is a sure way to reduce accident rate and make the workplace safer.

AMRs for efficient warehouses – summary

Currently available AMR trolleys can provide the full range of transportation methods needed in transporting stock within or outside any type of warehouse. Autonomous Mobile Robots are also a great option when you’re looking for a way to reduce labour costs, while increasing the efficiency of transporting and unloading cargo. Due to technologies implemented in AMRs, they can also significantly increase the level of safety and quality of warehouse work. Moreover, the whole fleet of robots can be easily programmed in a Warehouse Management System, which can be accessed remotely and require only one supervisor.