Metal stamping or precision metal processing is a basic method of plastic processing. Generally, sheet metal is used as raw material, and the die on the stamping machine is used for the reciprocating motion to process into well-designed hardware products or complete independent products. Metal stamping usually applies pressure to the metal sheet at room temperature so that the metal sheet is processed into the designed shape through the mold. Some thicker (above 11MM) and special-shaped 3D products will also be formed by heating if necessary. The products produced by metal stamping suppliers have a wide range of applications, such as computers, electronic equipment, medical devices, consumer electronics products, etc.

Let’s Take a Look at What Kind of Process Metal Stamping Usually Has?

The metal stamping process can be broken down into 4 following steps:

-

Planning and Design

The first step of the metal stamping processing technique is mold design. That is, the metal stamping supplier conducts mold design, evaluates the stamping process, and uses equipment according to the customer’s product shape, such as cutting, punching, bending, stretching, etc. The number of stamping works and the tonnage of the stamping equipment used are different, depending on the shape of your product.

-

Preparation of Dies

Each product needs a customized mold (except general hardware products on the market). Once your product is processed, designed, and processed into a mold according to the design draft, this mold will become a special tool for your product.

-

Punching Forming

After the mold is made, the product will be stamped by stamping equipment. At this time, after the flat material is processed through various processes of the mold, such as cutting, punching, bending, stretching, etc., the product is processed.

-

Quality Check

After the stamping product is formed, the metal stamping manufacturer will conduct quality inspection through microscopes, projectors, imaging equipment, etc.; refer to the product drawings you designed to test and proofread the product size, appearance, performance, etc. Finally, you will be provided with satisfactory products.

Benefits of Precision Metal Stamping

-

Greater Accuracy and Precision

One of the most significant advantages of metal stamping is its level of precision and accuracy. The molds used in metal stamping have precise mechanical positioning functions, plus the sensing and monitoring of sensors and optical vision equipment, which fully guarantees the accuracy and consistency of products.

-

Money Saving in the Long Run

Metal stamping can be incredibly cost-efficient for you in the long run. Once the mold is made, the subsequent large-scale product orders are processed with low cost and fast production efficiency. At the same time, according to the type of mold and the number of orders, automated unmanned production can be performed, which greatly reduces the procurement cost of your repeat orders.

Applications of Metal Stamping

Nowadays, metal stamping products are seen everywhere in our lives. Some of the most common applications are as below:

-

Automotive Industry

Metal stamping processing technique is considered a crucial part of the automotive industry. Automotive manufacturers use metal stamping techniques to manufacture a wide range of metal parts. That’s because this technique saves energy and has high production efficiency. Also, it is easy to operate and requires less technology for operators. More importantly, the processed parts have good dimensional consistency. The parts that use precision metal stamping in the automotive industry are mainly used for: window and wiper motors, seat locks, power terminals, brake components, rearview mirror mounting plates, camera components, etc.

-

Medical Device

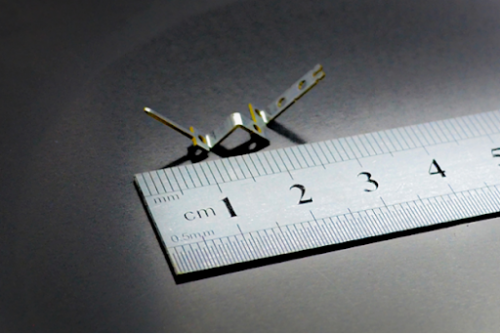

The development of sophisticated medical devices and instruments has helped facilitate the growth of the medical industry. The metal stamping industry also plays a key role in their development. Especially some precision tiny metal parts, such as heart stents, atomizing sheets in atomizing equipment, stomach/intestinal lens components, etc.

-

Consumer Electronics

Metal stamping suppliers develop a wide range of parts in the consumer electronics industry. They are particularly used for manufacturing products such as mobile phones, tablets, laptops, notebooks, smart wireless earphones, smartwatches, etc.

Hashimoto – The Leading Metal Stamping Suppliers and Manufacturers

Metal stamping is ideal for the production of small parts and components. At this time, you need to choose a reliable metal stamping supplier to help your products be more competitive in the market. And Hashimoto is your best choice in the metal stamping industry. Here’s why people trust them.

-

0.02-2.0mm Thickness

They can manufacture a wide range of products using both ferrous and nonferrous metal alloy materials with a thickness ranging from 0.02mm-2.00mm as required.

-

40+ punching machines & optical grinding machines

The company employs the latest state-of-the-art technology and machinery to manufacture products. Their production line employs over 40 punching machines that are capable of both small and large-volume productions. Meanwhile, they also have precision equipment for processing molds, such as optical grinding machines.

-

Both portrait measurement systems and automatic measuring systems are available.

Hashimoto uses sophisticated software and tools, including three-dimensional measuring instruments and image automatic measuring instruments, to achieve accurate, efficient, and error-free measurements to ensure quality.

-

Comply with ROHS and REACH standards

Hashimoto is 100% compliant with all industry standards, including ROHS and REACH.

-

Industry-Leading Experience

They have been operative since 2002; also, the team in Hashimoto has the necessary experience needed to take on all kinds of projects.

About Hashimoto

Hashimoto specializes in both the small and large-scale manufacturing of a diverse range of products. They are committed to delivering only quality products manufactured with precision and binding quality control at every step of the way. Furthermore, they are ISO9001, ISO14001 and IATF16949 certified!

If you are looking for a reliable metal stamping manufacturer, look no further; visit the Hashimoto website today!

Learn more: https://yijinsolution.com/news-blog/top-10-metal-parts-manufacturing-companies-in-china/

Interesting Related Article: “What is Lean Manufacturing? Definition and Examples”