As supply chain troubles and challenges mount in a world continuing to operate during an ongoing global pandemic, consumer behaviors and corporate sustainability commitments are reshaping how goods are packaged and transported. One of the greatest areas for improvement in terms of sustainability—packaging and logistics—affects every single product bought and sold.

As consumers age, younger generations prove that online shopping is entirely changing the flow of commerce and how and where people are purchasing products. Single-destination packaging and shipping have impacted the overall sustainability of corporations and challenged the corporate pledges made by many companies. The physical logistics of how packages are routed and delivered to consumers or other businesses have not changed dramatically in decades. But attempts have been made to lessen waste, energy and labor in these endeavors. One of the most notable changes to these industries has come in terms of packaging products in recent years.

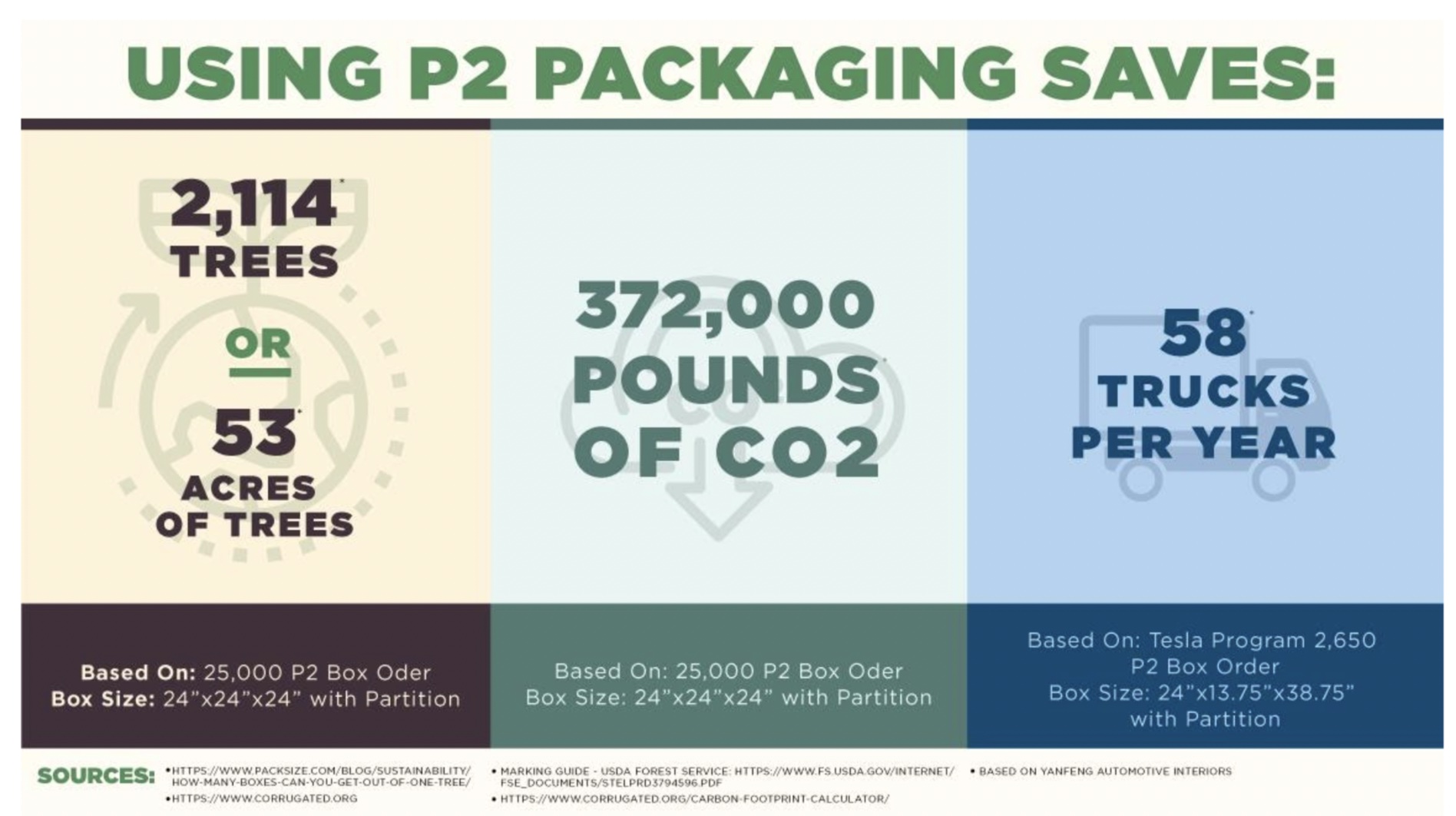

P2 Packaging, based in Columbus, Ohio, has developed and manufactured a patented box design that eliminates wasted space, collapses quickly, and can be reused several times. This means fewer boxes used for shipping, less space to store boxes between loads, and fewer workers required to transport products. Ultimately, this results in significant cost savings and a lessened impact on the environment, regardless of industry.

Sustainability is traditionally viewed as meeting the needs of the present without compromising the ability of future generations to meet theirs. The 1969 National Environmental Policy Act (NEPA) determined that sustainability is concerned with three pillars: economic viability, environmental protection, and social equity.

Maximizing cost-cutting while addressing sustainability expectations is a massive step when considering packaging and logistics. However, P2 has found the appropriate recipe to juggle all three pillars of sustainability by applying the concept to an area of business—regardless of industry—that is omnipresent, no matter the business type.

One of the industries we have the most to gain from adopting packaging design, such as P2, is the automotive industry. Thousands upon thousands of parts are packed and transported for every single vehicle. With some carmakers producing particular models by the millions, the cost savings for auto manufacturers is tremendous. In fact, a current P2 client has saved nearly 10 million dollars in shipping cost in the last couple of years by using P2 products as a returnable, getting up to ten turns per container. And that same positive impact is being felt in environmental effects as well.

Reinventing the shipping box has been likened to reinventing the wheel, with the difference being that not many improvements can be made to the wheel at this juncture. However, approaching the use and design of a shipping box has already proven to be incredibly fruitful, not only in reducing corporate expenditures but also in terms of environmental toll. P2’s reimagining of this simple tool and its applications has saved loads of money and reinvigorated the conversation regarding sustainability and how far-reaching an impact something as simple as a box can be.

For more information, please contact Rudy Youell, president, at 614-378-4490 or visit p2packaging.com.

You may be interested in: Sustainability Reporting: What is the Cost?