Every aspect of our daily lives, both at home and at work, have been affected or altered in the face of Covid-19. Many industries are struggling to keep people employed and simply keep their doors open.

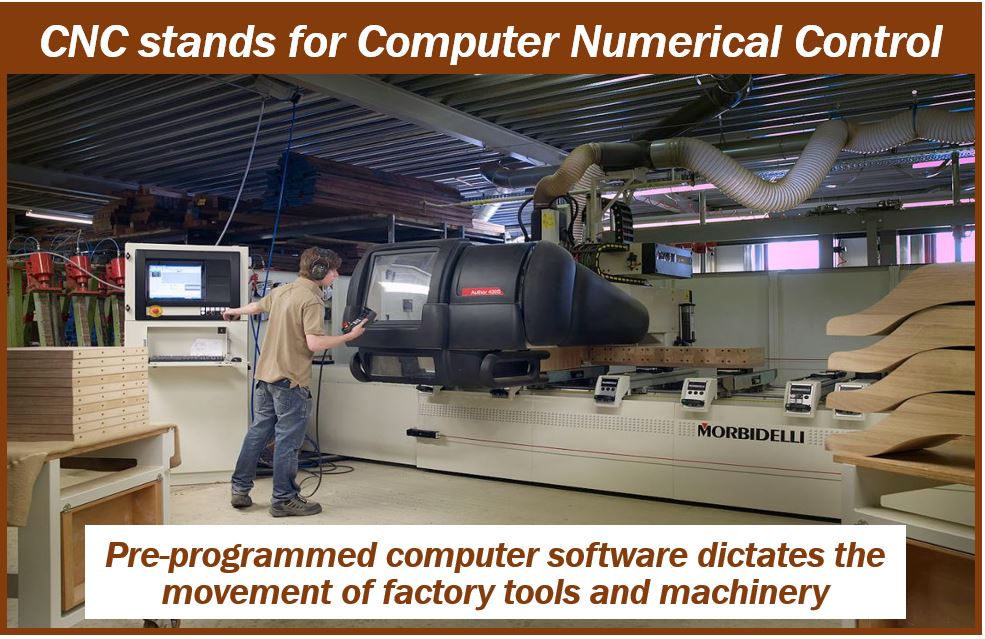

But then there are some industries that are becoming even more innovative in the face of the pandemic. CNC machines that operate in the latest ‘smart factories’ are rising to the challenge, in spite of massive challenges.

In the beginning of the Covid-19 era, these smart factories saw a decrease in labor hours and many employees were becoming a bit unsettled at the thought of being laid off, either temporarily or permanently.

While the demand for orders in CNC machining facilities has dropped in the face of this pandemic, the demand for more critical items has taken the place of regular orders.

“With the versatility of automation, many major manufacturers were able to switch gears to produce personal protective equipment (PPE) and many of the medical devices needed at this time. It’s been very inspiring to see how businesses have evolved and risen to the occasion, coming together for a common cause,” says Tom Kohm, President & CEO of Premier Equipment, the largest seller of used CNC machines.

Changing the Face of Production and Increasing It

Many facilities that are capable of providing precision parts have been called on to retool their smart factories to make essential items needed to combat Covid-19.

One such company, Smith and Richardson of Geneva, Illinois has seen a production increase of over 400% as they have retooled to make 6 different precision parts for ventilators.

At the start of the pandemic, Rich Hoster, the president of Smith and Richardson already had a plan in place to deal with the oncoming economy. That plan was quickly changed as these ventilator valves that his company makes started seeing huge increases in demand.

In the past, they would use one or two employees to operate five or six machines. Under their new plan, each individual machine has its own operator. The rest of the employee workforce was able to keep their employment status by becoming a part of an extensive factory wide sanitizing program. This kept everybody working without a single lay off.

Other Areas of Interest

Smith and Richardson are just one company among hundreds that have been called on to help with fighting back Covid-19. Many factories have been changed from making their usual regimen of precision parts to producing essential medical equipment needed in this fight.

Everything from ventilators parts to PPE (personal protective equipment) have allowed many of these smart factories to remain open for business, in spite of tremendous challenges. Innovation for the win!

Interesting related article: “What is Automation?“