Research by Bain & Company and Facebook reveals that the COVID-19 pandemic accelerated e-commerce and other digital trends in the Southeast Asian region. The study shows that the trend of consumers buying things online is likely to become the new norm. “One of the trends we identified was essential online shopping, and that’s here to stay,” says Praneeth Yendamuri, a Bain & Company partner.

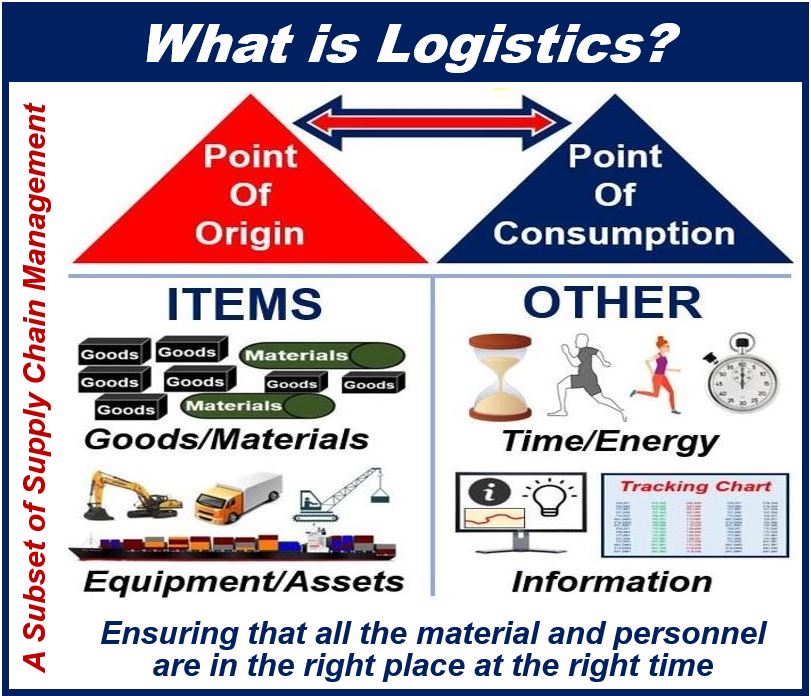

Going online successfully, however, requires dependable logistics. After all, only a few products can be converted into digital format and transmitted to customers. Unlike music and movies that can be sent to buyers as digital files, groceries and other physical goods need to be physically delivered.

Challenges and opportunities in logistics

A PostNord whitepaper explains the importance of logistics or delivery services in customer satisfaction and patronage. “Time really is money today, and deliveries need to match the new requirements consumers are making with regard to convenience, freedom of choice and control,” the whitepaper writes. No matter how good a product is, customers will end up with a bad impression if its delivery leaves a lot to be desired.

“I would have given it a 5 out of 5, but the delivery was too slow.” This is the gist of one of the most common complaints customers post on Shopee, Southeast Asia’s biggest e-commerce site. The situation is not that different on Lazada, the Alibaba-owned e-commerce powerhouse in the region.

In worse cases, the delivered items do not only come late–they can also be damaged. Complaints of broken tablet or laptop screens, for example, are not uncommon. These have been happening recently especially as laptop and tablet computer sales surge with schools shifting to online or blended education modes. With food and grocery deliveries, delivery delays and considerable defects in the packaging are often reported.

Delivering fragile or delicate products is not easy especially when large volumes and a heterogeneous mix of items are involved. Companies that venture into the business of logistics need to become well-versed with the different aspects of the supply chain. It is not enough to have vehicles and manpower. Logistics companies also need to know how to gather and analyze data to ensure efficient operations and meet customer expectations.

Despite all the challenges, an industry report projects a 17.6% year-on-year growth for the global logistics market in 2021. This figure takes into account the probability that COVID-19 will remain a problem in the year ahead. “The global logistics market size is projected to grow from USD 2,734 billion in 2020 to USD 3,215 billion by 2021,” the report writes. Demand for logistics solutions will continue growing because of the inevitability of online modes of doing business.

Smart logistics

To address the challenges, smart logistics or delivery systems are becoming necessary. Research and consulting firm BCI Global defines smart logistics as the effective use of data in optimizing the organization, planning, control, and execution of the flow of goods. To emphasize, it is vital to have adequate and reliable data to offer real smart logistics. Unfortunately, not many companies are able to handle data gathering and analysis competently.

Due to the scale of operations and details needed in ensuring efficiency, big data now plays a big part in logistics. It is for this reason that data logging platforms have been designed to reduce wastage by enabling transparency for all relevant parties.

Delivery data collection and analysis are crucial in coming up with better logistics plans to meet customer expectations and reduce complaints especially during the pandemic, wherein shipping delays and mistakes can be costly.

Moreover, smart logistics allow companies to identify weak points in their operations and prevent the shipping of goods that may have been compromised. It is useless to ship items when they will eventually be returned by the recipients because of defects or other issues.

Cold chain logistics

Cold chain monitoring in the supply chain is one area where smart systems are markedly useful. A cold chain is a supply chain that necessitates temperature control to provide an uninterrupted series of production, storage, and distribution processes that all involve refrigeration or some form of temperature management to prevent spoilage.

To ensure that goods are kept at the right temperature levels, it is essential to continuously keep track of their state and movement. This is a challenging task especially when large volumes are involved. Consistent and real-time data logging is vital and the workers responsible for overseeing the products make use of advanced tools to monitor temperatures and keep products within the predetermined ranges. Manual tracking would be too inefficient and will likely result in large losses.

The global pharmaceutical industry, where 30% of deliveries end up with spoilage or some form of damage, benefits significantly from smart cold chain logistics. Efficient methods of persistent and consistent data monitoring enable dramatic reductions in product damages while in transit.

Supporting entrepreneurs and businesses

The 2019 BCI Supply Chain Resilience Report shows that 70% of industry professionals believe that effective supply chains result in better customer service. Unfortunately, supply chain statistics from Logistics Bureau reveal that 57% of businesses have poor supply chain visibility. As such, there is a need to adopt smart logistics, which starts with having access to accurate, reliable, and real-time data.

Data is vital in planning travel routes for deliveries to avoid roads that may be blocked due to local community quarantine guidelines, for example. Likewise, it is essential in ensuring the quality of products delivered, thereby avoiding instances of customer disputes or complaints. Data is also important in ensuring the safety of the delivery personnel. A possible 10% to 15% logistics labor force reduction is expected in 2021 because of COVID-19 infection, so it is also necessary for companies to protect their employees.

Logistical challenges expectedly worsen during a pandemic. In response, logistics companies need to adopt smart solutions. Failing to understand and find ways around the difficulties of product delivery or sales fulfillment does not only mean failure on the part of logistics companies. More importantly, they adversely impact the supply chain in general.

Video – Logistics

Interesting related article: “What is the Supply Chain?“