The advent of technology has affected every industry in the world. Today, it is not only easy to make orders online but also to purchase quality products that have been manufactured and designed using the best technologies. Among the many materials used in the manufacturing industry, aluminum is one of the most common. It is highly preferred for making cross-sections because it is very sturdy. More so, it is highly effective in the extrusion procedure. Aluminum extrusion is the process used to create objects that come with a fixed cross-sectional profile.

A lot happens during the extrusion process, including heating of billets and transferring them to the cradle for profiling. After the aluminum extrusion process, the surface is then treated to give the final products different contrasts. This will depend on the clients’ needs and requirements. The number of companies offering aluminum extrusion is growing exponentially these days thanks to the ongoing technological advancements. This makes it easier for customers to find the best aluminum extrusion profiles.

Why Aluminum Is Good for Extrusion

Interestingly, there are many reasons why aluminum is the best material for extrusion. They include:

- Lightweight

Many hose coupling manufacturer opt for aluminum because it weighs less than other metals such as iron, copper, brass and steel. Therefore, aluminum products are easier to handle and less costly when transporting them.

- Sturdy

Through the extrusion procedure, aluminum frames can be made as strong as the manufacturer wants. This is achieved by varying the thickness of the frame or opting for internal strengthening in the profile design. When subjected to cold weather, aluminum frames become stronger. This aspect has contributed a lot to the ever rising demand for aluminum products. Aluminum is also resilient and combines flexibility with strength, and that is why it is mostly used in the automotive industry.

- Corrosion resistant

One core factor that many customers consider when buying products made from different materials is the ability to resist corrosion. Aluminum products do not rust and their surface is also protected by its natural oxide sleeve. Aluminum can also be anodized to make it more corrosion resistant.

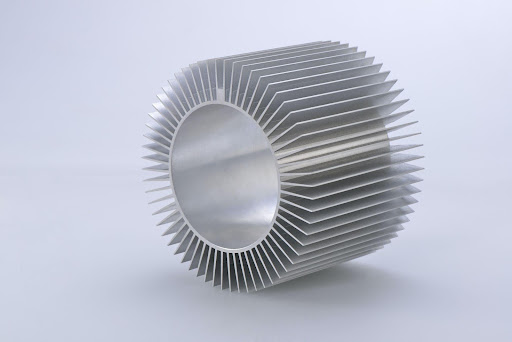

- Thermal conductor

Aluminum is a good conductor of heat than many other common metals and therefore its extrusions are good for any application that can require dissipation or exchange of heat. The design flexibility of aluminum extrusions also makes it easy for manufacturers to optimize heat conduction in other components.

- Non-magnetic

Aluminum extrusions are also ideal for high-voltage applications and in electronics as they don’t require any magnetic charge.

- Easily customized

Aluminum extrusions stand out from the rest because they can be easily tailored. This means that it is easy to design a profile that can meet the aesthetic and functional needs of a customer.

- Non-combustible

Aluminum does not burn even when exposed to high temperatures and it doesn’t produce toxic fumes when burnt.

With the many advantages of aluminum extrusions, it should not be taxing to choose the best in the market. Order aluminum extrusion profiles from a dealer who has been in the market for long. He or she should be someone who will meet the order requirements. The dealer of choice should be an expert who understands the intrigues of aluminum extrusion.

You may be interested in: Aluminum Machining: A Complete guide