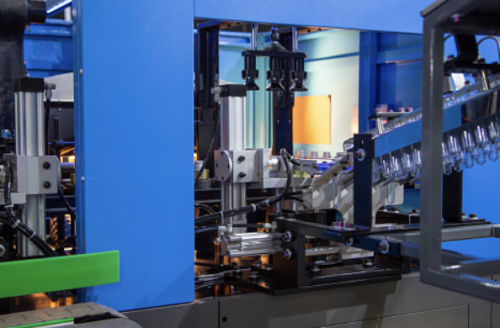

You may be considering purchasing a blow molding machine for your company’s production line. There are several advantages to purchasing an automated machine for your production line, including increased production capacity and cost savings. This machine is an excellent option for manufacturers that want to control their production costs and specifications while increasing sales and profitability. If you have no experience in manufacturing, you can use a video to help you decide whether a blow molding machine is right for your needs.

The EBM process starts with pelletized raw materials that are fed through a screw-and-barrel arrangement. Once inside the barrel, the molten material is forced through a die, arranged in a vertical position to create a round or oval shape. This process allows a product to have many different functions. A blow molding machine is also easy to use and has an intuitive user interface. To operate the machine, simply press the Start button.

Continuous-extrusion blow molding is an efficient method of manufacturing plastic objects, which involves continuous homogenizing. During the manufacturing process, a parison is cut into its desired length, and the mold is divided into different configurations. A shuttle press can hold one or multiple parisons and is often cheaper than other configurations. Its lower throughput is a disadvantage of this method. In addition to continuous molding, extrusion blow molding machines can also produce hollow thermoplastic objects.

An injection blow molding machine combines the benefits of two processes. First, the plastic raw material is melted and homogenized in a plastifier, which is a reciprocating screw. The screw assembly and the extruder barrel help create the plastic shape. The plastic raw material feeds into the cylinders, which are shaped to create a plastic preform, plastic bottle, or plastic container. This is a relatively simple process and requires very little space.

Extrusion blow molding is the most common type of plastic blow molding. Melting the plastic material is the first step, followed by extruding the material into the mold. The air pushes the plastic into the mold, which is then locked in place by two halves. The two halves of the mold are then separated, and the plastic part is ejected. The extrusion blow molding process is also the fastest and most efficient.

Tips for choosing a blow molding machine.

When choosing a blow molding machine, the following tips will help you to get the right one:

-

Consider the machine type.

There are two types of blow molding machine: automatic and semi-automatic. The first can produce up to 16 parts per minute, while the second only 8 pcs per minute. If you need larger quantities, it is better to choose an automatic model as it can reduce production costs by 20%.

-

Look at the main advantages of each type.

Automatic machines are more productive due to their automatic feeding system that ensures increased productivity by eliminating human error and reducing downtime between operations. However, if you have a small production line or if your parts require complex designs then a semi-automatic might be better suited for your needs.Because its smaller footprint allows for easier integration into existing production lines without consuming too much space on site!

Interesting Related Article: “How to Grow Your Manufacturing Startup“