The manufacturing industry has prerequisite standards that are necessary for safety, quality, and purity. To be licensed, you also need the right tools, facilities, and expertise. These are essential to provide goods that meet the expected professional and legal demands. Irrespective of the industry you operate in, the below five tools are necessary for manufacturing operations. They enhance efficiency for increased output.

1. Automated Assembling Equipment

The use of robotics in manufacturing is now the new normal. It offers speed, apt material handling, and accuracy. In an industry of such intense competition, having efficient, quality production is vital. The SCARA robot can help in this respect.

SCARA is an acronym for Selective Compliance Articulated Robot Arm. This robot is a flexible manipulator and its four degrees of freedom offers high speed and accuracy. The SCARA robot can also carry out a vast array of tasks and is used in virtually all kinds of manufacturing industries, from electronics to automotive. They also come with the advantage of being easily reprogrammable to meet changing needs.

2. Security Equipment

A typical manufacturing plant has many different activities going in. That’s why it’s vital to offer the right safety equipment. This includes the proper safety gear for staff and general all-around protection for visitors to your premises. It’s also a good idea to ensure that only authorized personnel have access to the room where most of the production occurs. This is to prevent risks of injury and to safeguard your property and products.

Also, there are crucial security tools every manufacturing business should consider. This includes high-resolution CCTV cameras, reinforced steel doors, and coded door locks. You can link all these up via an Ethernet system.

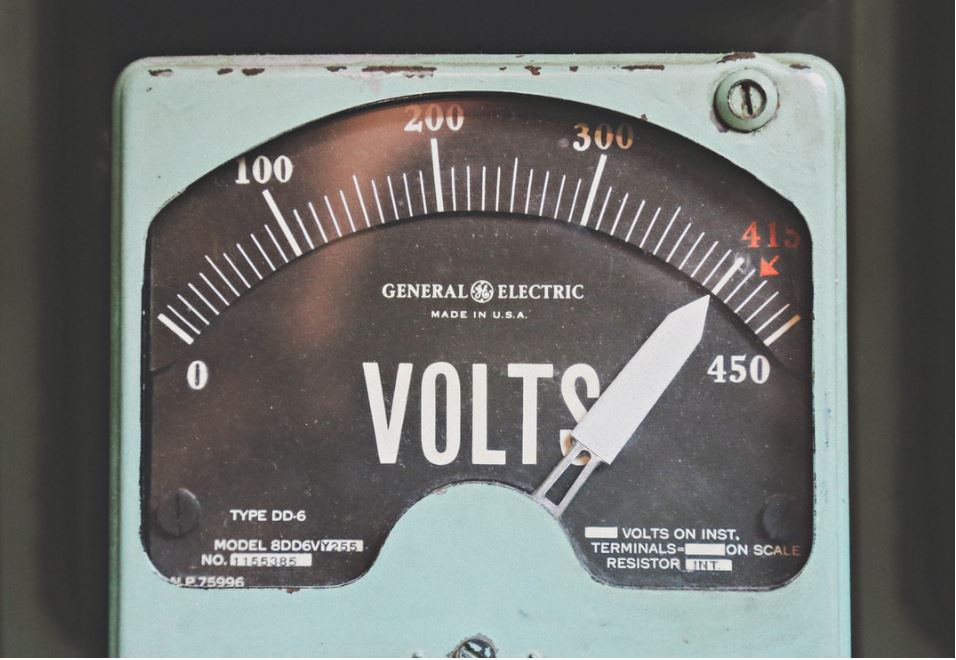

3. Reliable Power Source

Whether your manufacturing business is a startup or a large firm, it’s crucial to have a steady supply of power. This can be from the local power providers or private contractors. As long as you’re in the manufacturing business, this is important. That being said, relying on one power source comes with a considerable disadvantage. Anything can happen, and your manufacturing operation would be in jeopardy.

No doubt, a reliable backup is an effective way of guaranteeing consistency in the manufacturing process. For this to take effect, you can invest in a diesel or gasoline generator plant. Or, if you prefer a clean energy source, investing in a solar or a biogas plant is a better option.

4. Storage Units

You can’t sell all your products at once, so a good storage setup is a key element of the production process. Whatever industry you’re in, it’s vital to get storage systems with limited access and apt sensors. This will restrict entry to only authorized personnel. Changes in environmental factors that can alter the integrity of your product will be rapidly detected. This will enhance your quality control and quality assurance.

Tanks, drums, customized warehouses, and other systems are also available. However, a qualified I.T. consultant will help you integrate them with the latest technology. Besides, continuously educate your staff on the technology and the changing trends.

5. Analytics Tool

As a business owner, you will need a system to analyze performance. This will help you enhance the overall manufacturing process. A standardized and aptly efficient manufacturing process translates into an efficient supply chain. This guarantees high-quality products and assures customer satisfaction.

In this age of information technology, software is available to make this easy. There are generic versions you can use to analyze the desired function. If the need arises, you can get tailored-made ones to measure the needed metric. These analytic tools aren’t just limited to staff and production. You can use them to evaluate materials from every supplier.