If you’re running a business or a manufacturing company, you need to know how to use measuring machines to keep up with the latest technology and keep track of your equipment. Measurement and analysis are an important part of business and manufacturing setting. With these tools, you can easily do a simple measurement, as you would with a tape measure, and do a more detailed analysis or get a rough estimation of a number of dimensions.

Below are the four ways to use measuring machines in a business and manufacturing setting.

Measuring Machines: What Are They?

A measuring machine is a piece of equipment that will allow you to make measurements and put things into formulas that will calculate how long something will be and where it will be placed in your space. There are many different types of machines that can be used for measuring, but there are a few different types that are best suited for use in a business setting. These include mechanical, electrical, and electronic measuring machines.

- Mechanical measuring devices – They’re not very commonly used in manufacturing settings due to the fact that they’re usually very expensive. A lot of money has to be spent to purchase these types of measuring machines, and they’re often hard to use as well. Furthermore, they have to be taken apart and put back together, and they also take up a lot of space, which doesn’t make them a practical way of storing inventory.

- Electrical measuring devices – They’re generally less expensive than mechanical ones, and they’re also easier to use. Electrical measuring machines work by getting a reading out of an electrical source and, then, using this reading to determine the dimensions of the item that’s being measured. Electrical measuring devices can work with batteries or can work without a battery. Also, they work very quickly.

- Electronic measuring equipment – This isn’t commonly used in manufacturing settings because they’re usually quite large and can be very difficult to use. A lot of the time, they’re very complicated and require a professional to be able to use these devices. If you’re going to be using one of these machines for inventory measurement purposes, it’s best to find a machine that’s easy to use and reliable.

Therefore, if you’re looking for the best measuring machines for your business, reliable providers, like https://eleymet.com/, can help you. From full-scale metrology solutions to basic measurement devices, they can cater to your company’s needs.

Measuring Machines: How Can You Use Them In Business And Manufacturing Setting?

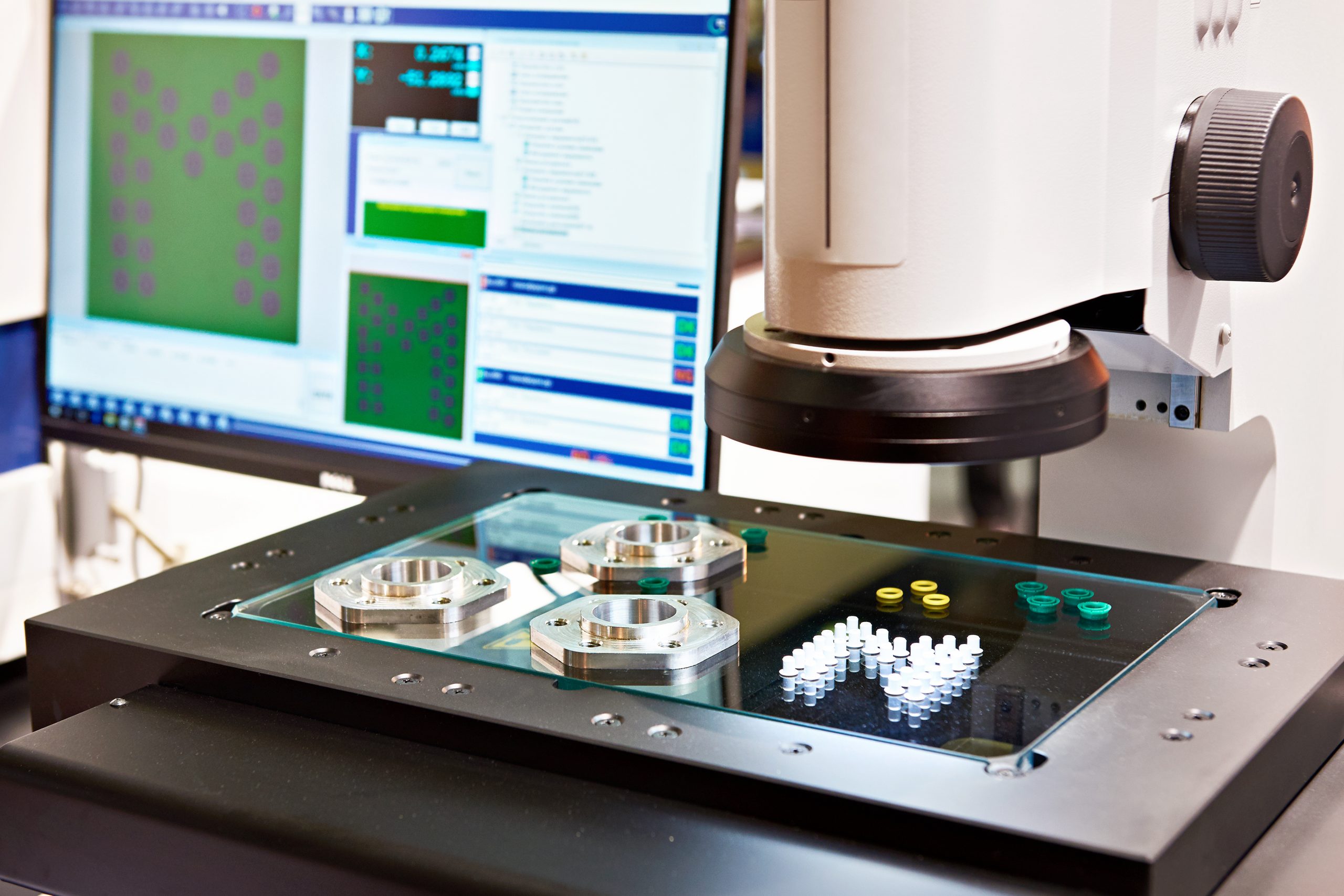

Typically, measurement machines are used in a lot of different settings, and there are many different reasons that they might be needed. When you’re looking to make sure that the material being used for your business is of topnotch quality and meets all of the requirements, then, you can use one of these machines.

There are different ways to use measuring machines in a manufacturing setting, and these can include:

-

To Know The Exact Size Of Your Products

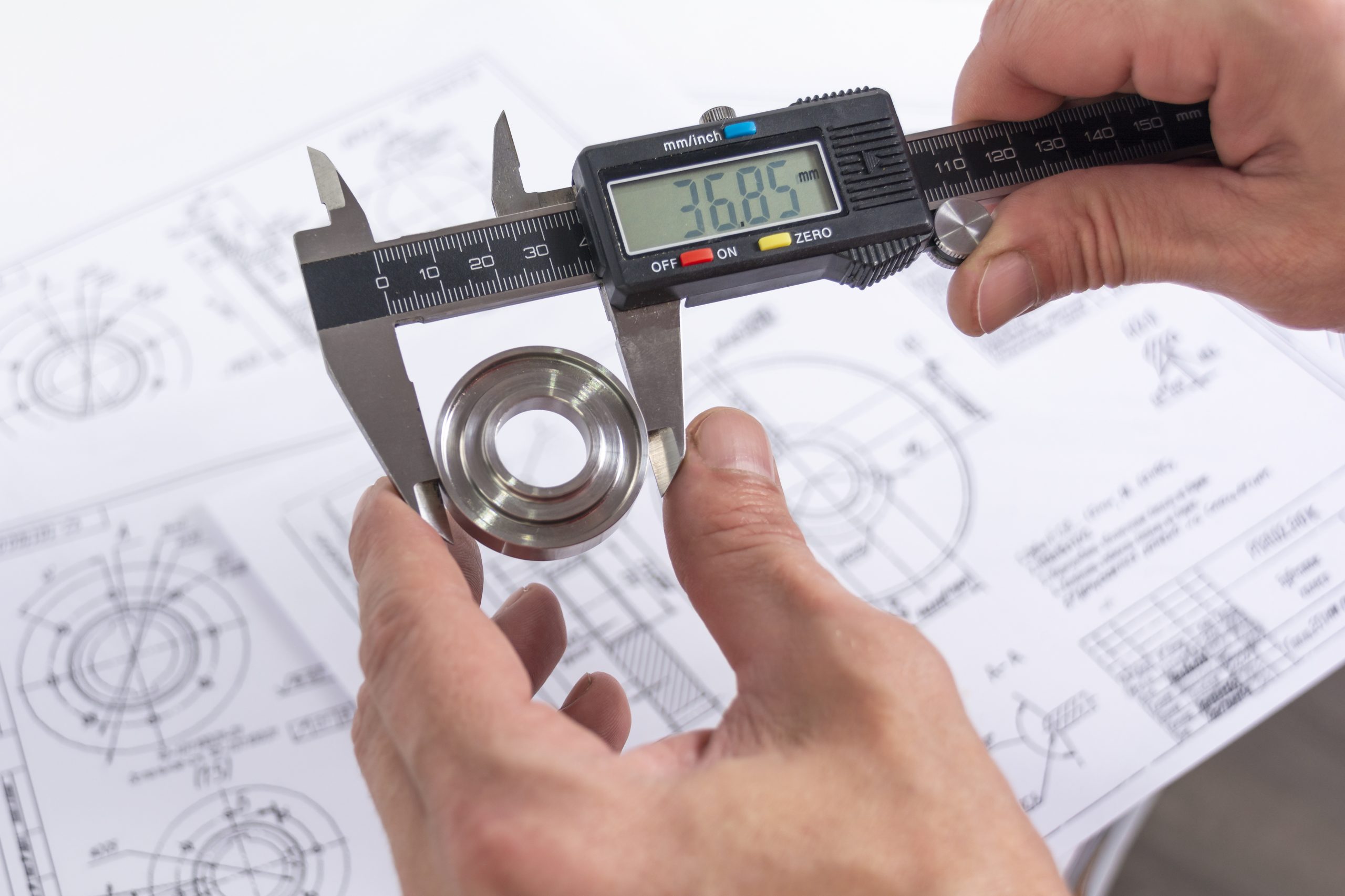

As a business owner, you always want to make sure that the product you want to have made is the exact size that you need. It might be difficult for you to do this on your own, but it’s also important to be able to measure different parts of your product and to be sure that they’ll fit right before you have them made.

This is one reason why measuring machines are there to help you. Depending on the specific equipment you need, you can use these innovations to measure the exact size of your products. Lastly, these devices can help improve how mass production works.

-

To Measure Volume Of Chemicals And Sizes Of Various Materials

In most cases, you’ll find that the measuring machines will have the ability to accurately measure volumes of materials. For example, you’ll find that these devices will have the ability to measure the volume of any material, including chemicals. There are also some types of measuring equipment that will have the ability to measure the size of materials as well. These types of measuring devices will have an accuracy level that can be extremely high when it comes to measuring various materials

-

To Determine The Size Of The Container

Another reason that your business might use measuring machines is to be able to figure out what size of the container you should use to store the product that you’re trying to measure. There are a lot of different containers that you can use for measuring products, and you can even use boxes to store them as well. This way, you won’t have to worry about having a large container on hand or having to keep track of different sizes of containers when you’re measuring. This is one reason why a lot of people will make use of measuring machines.

-

To Ensure Accurate Inventory Measurements

As mentioned, there are many different ways that measuring machines can help in a manufacturing setting. One of these is maintaining accurate inventory measurements, so there are many ways to keep track of all the inventory that’s being used in the business.

Having accurate inventories is vital for businesses because these help them in planning and budgeting for their daily operations, and allow them to make better business decisions. With measuring machines, your company can maintain accurate inventories, which makes sure the products or services you’re selling are of excellent quality.

Conclusion

With the information mentioned above, it’s clear that measuring equipment can be very useful in many different types of manufacturing and business settings. They can make the job easier and more accurate, and they can also be very useful for companies who want to ensure that they get the best possible materials for their products.

However, when it comes to choosing the best type for your needs, it’s important to remember that your choice might depend on several factors. First of all, you’ll need to make sure that the measuring machine that you choose isn’t only reliable, easy to use, and affordable, but also one that can provide the accuracy that you need to ensure that the items you’re measuring are of the highest quality.

Interesting Related Article: “How Does Mass Production Work? A Helpful Guide“