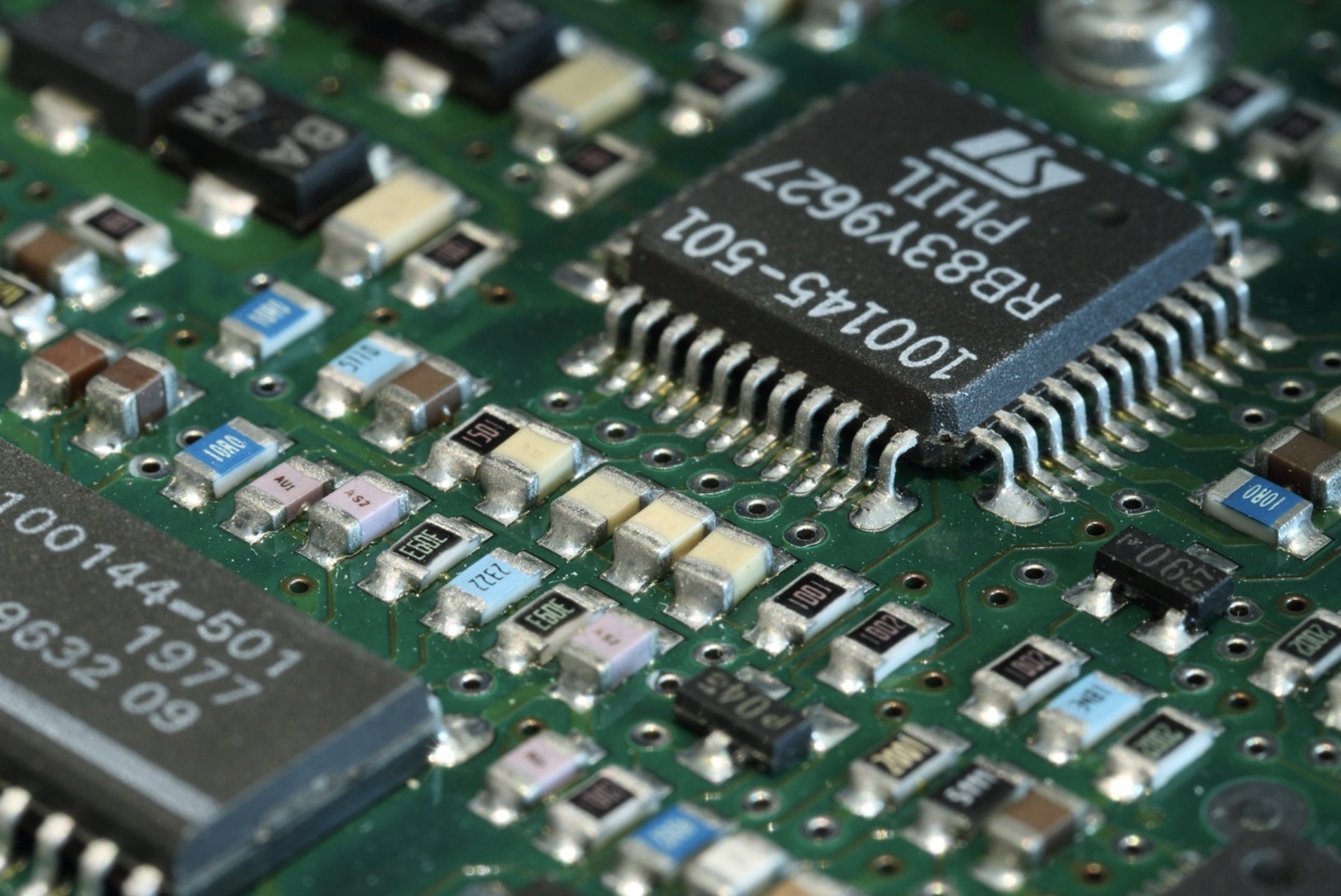

PCB Assembly is one of the most commonly contracted tasks by professional EMS (Electronics Manufacturing Service) providers. “PCB” stands for Printed Circuit Board. PCBs are those little green chips that are implemented into electronic devices we use every day. They can be considered the hearts of those devices.

What is the PCB?

PCBs can be made of different lavers and elements but most of the time they are made of: some kind of substrate (base material), conductive copper foil, solder mask (is to keep all of the elements together), and a final layer of silkscreen. There are, for example, rigid PCBs, flexible PCBs, metal core PCBs, and so on.

How PBCs are being made?

PCBs are being made through PCBA (Printed Circuit Board Assembly) – a manufacturing process. Several different technologies can be used to manufacture PCBs and the most common ones are: Surface Mount Technology and Thru-Hole Technology.

PCB Assembly Process

Of course, details of the PCB assembly process can differ based on what technology is being used but there are some steps that can be considered universal for all PCBAs. Firstly, the solder paste should be placed on the board, and then all of the other components. Usually, it is being done by a pick and place machine. Then, in order to merge the elements to the board, the process of reflowing soldering occurs. The next step is quality control: manual checks and automatic inspections.

Box Build Assembly

Box Build Assembly is a process of electromechanical assembly beyond just PCBA. It is a comprehensive service provided only by knowledgeable manufacturers. An outsourced company will be in charge not only of the manufacturing process but also of such tasks as:

– configuration of products and testing them,

– installation of software,

– warehousing, labeling, packaging, and shipping,

– aftermarket services,

– maintenance and repairs.

There is no need to handle the rest of the process besides PCBA if all of the tasks can be submitted to professionals in their field. Outsourcing a competent EMS provider can save not only time but also money. All that the customer has to do is to provide a manufacturer with detailed information about the project – the more the better.

How to outsource the best EMS provider?

A suited EMS provider (see: https://asselems.com/en/pcb-assembly) should have a high-end technical infrastructure and a staff of experienced engineers. Outsourced company has to be able to, apart from just manufacturing, make prototypes and run solid tests to check the quality of their products.

It is best to request recommendations and seek independent opinions online about a company you are interested in. The customer service of any proper EMS provider should be communicative and reliable. You want to make sure that there will be clear communication all through the manufacturing process if you decide to hire a certain company.

Last but not least, remember that the best price rarely means the best service and end product. Better to seek the most cost-efficiency solution.

Interesting Related Article: “Basic Common Issues That Affect PCB Designs“