Rapid prototyping is an aspect of creating parts or models of an object.

It is a collection of methods employed in the design and creation of life-sized objects; most times, the objects created are models or prototypes of the real deal.

This fabrication or creation is done with the aid of a 3D printer, and additive layer manufacturing can be alternatively used.

How Does It Work?

With rapid prototyping, you can bring life-sized models or even smaller versions of your original plan to life. It makes things like presentations more comfortable and more realistic.

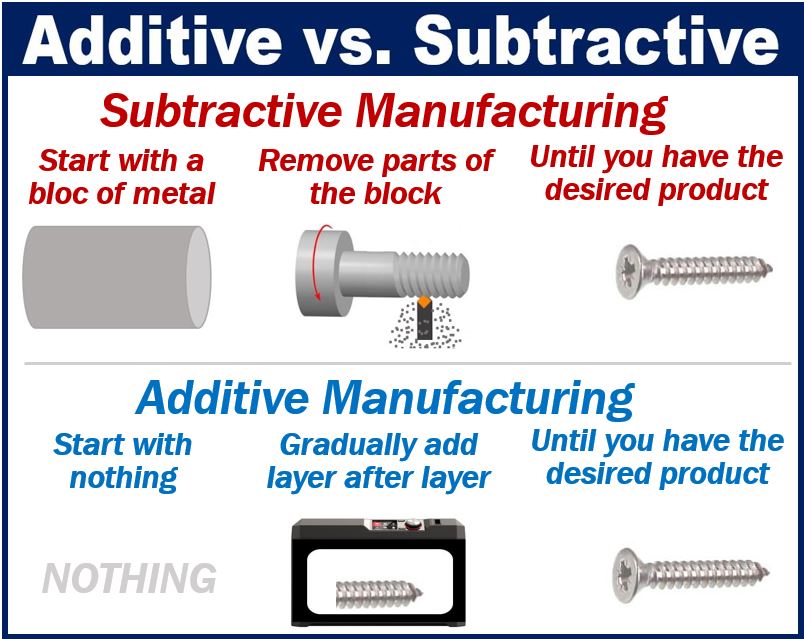

There are different methods and technologies involved in successfully carrying out a rapid prototype; the most commonly used method is the additive method.

Still, there are other ways that you can about it.

-

Subtractive

This method is very similar to sculpturing. With the subtractive method, the material you want to work with is reduced progressively to form whatever it is you have in mind.

-

Compressive

With the compressive method, you will be dealing with a less dense startup material with a certain degree of malleability. The pressure is applied to give the required form, and then it is solidified.

Types of Rapid Prototyping

There is more than one type of rapid prototyping, and it includes;

-

Stereolithography (SLA)

The Stereolithography or Vat Photopolymerization method involves the use of photosensitive liquid and UV light.

The liquid is solidified with the use of UV light, which is controlled by a computer. This method is cheap and easy to perform.

-

Selective Laser Sintering (SLS)

The selective laser sintering method as the name suggests makes use of a laser to mold the intended model. This method is suitable if the model you’re making is metal or plastic.

The material used by this machine is in powdered form, and the laser melts this powder together; it then spreads the fused material layer by layer to give the desired model.

-

Fused Deposition Modelling (FDM)

The fused deposition modeling is one of the cheapest forms of rapid prototyping.

The method uses a thermoplastic material that can be quickly melted down and then reshaped layer by layer to give the desired model programmed into the computer; it uses 3D CAD.

-

Selective Laser Melting (SLM)

The selective laser melting or powder bed fusion is one of the most reliable forms of rapid prototyping.

It is used to create renditions with great strength and durability. It is an expensive type of rapid prototyping, and it is used in making actual parts of machines, not just prototypes.

It uses a method similar to that of the selective laser sintering machine; it melts the powdered form of the materials and fuses it layer by layer.

-

Laminated Object Manufacturing (LOM)

The laminated object manufacturing or sheet lamination is also another cheap and easy-to-use method.

It uses laser beams to shape laminates and join them bit by bit to make the required model.

-

Digital Light Processing (DLP)

Digital light processing makes use of UV light as well; it is used to harden photosensitive liquid. The method is like SLA, but it requires more attention.

-

Binder Jetting

The material used in this machine is also in powder form, but instead of a laser beam melting this powder and fusing it, it is sprayed with a bonding liquid to form layers.

The pressure is then applied to each layer to form the desired model.

Interesting related article: “What is 3D Printing?“