MIT scientists developed a 3D printing method to produce transparent glass on an industrial scale. They created a new manufacturing platform for the digital fabrication of transparent glass.

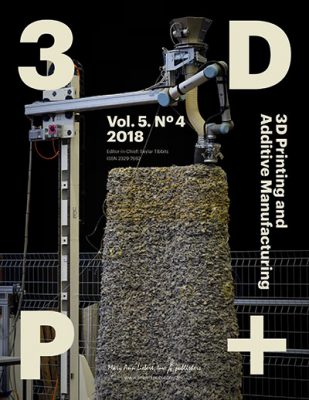

The G3DP2 platform turns molten glass into columns three meters tall. The researchers wrote about their work and achievements in the journal 3D Printing and Additive manufacturing (citation below).

In the article, the authors discuss the early G3DP2 printer. They used it to provide proof of concept of the feasibility of producing transparent objects through molten glass deposition.

Architectural output of transparent glass

The researchers also describe the complete redesign of the system. They upgraded the system to an industrial platform that can achieve architectural output.

3D Printing and Additive Manufacturing is published by Mary Ann Liebert, Inc. It is the only peer-reviewed journal that focuses on 3D printing and related technologies. (Image: liebertpub.com)

The upgraded G3DP2 platform had four objectives:

– Greater speed.

– Increased scale.

– Better reliability.

– Improved repeatability.

The researchers report on how to understand and control the behavior of printed glass. They also report on the platform’s control and engineering, its specifications, and the product design space.

In an Abstract that precedes the main article in the journal, the authors wrote:

“G3DP2 is a new AM platform for molten glass that combines digitally integrated three-zone thermal control system with four-axis motion control system, introducing industrial-scale production capabilities with enhanced production rate and reliability while ensuring product accuracy and repeatability, all previously unattainable for glass.”

What is 3D printing?

3D printing is a process of making 3-dimensional objects from a digital file. It is a type of additive manufacturing.

The creation of 3D objects is possible using additive processes. The 3D printer lays down successive layers of material until it finishes creating an object.

The opposite of 3D printing is subtractive manufacturing. Subtractive manufacturing involves hollowing/cutting out a piece of plastic or metal with, for example, a milling machine.

Over the past decade, 3D printing has entered mainstream manufacturing. It is rapidly transforming the shop floor in several industries.

Citation

“Additive Manufacturing of Transparent Glass Structures,” Chikara Inamura, Michael Stern, Daniel Lizardo, Peter Houk, and Neri Oxman. Additive Manufacturing of Transparent Glass Structures. Published Online: 17 Dec 2018. DOI: https://doi.org/10.1089/3dp.2018.0157.