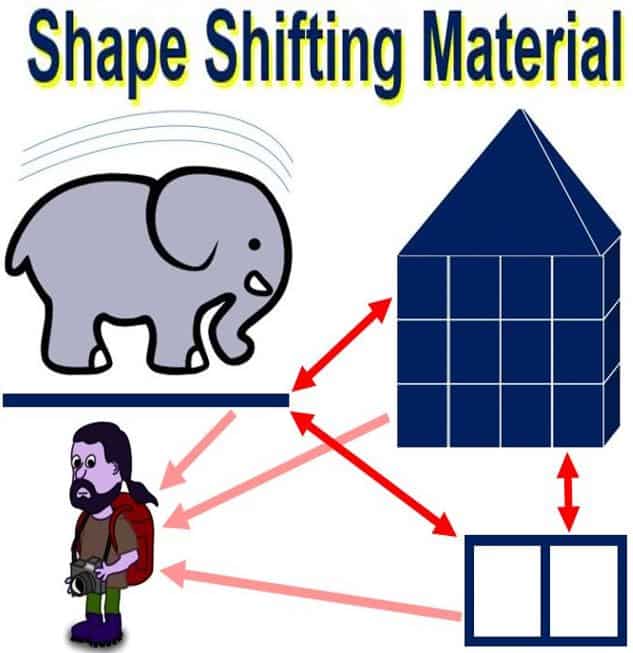

Imagine a house than can shape shift into a wall in seconds, then turn into a window and any number of different structures at simply the flick of a switch. Harvard scientists say they have designed an incredible material that can do this – the new shape-shifting foldable material is remarkably versatile, self-actuated and tunable.

The researchers explained in the journal Nature Communications that their amazing creation can change volume, size and shape. It can even fold out flat to withstand very heavy weights, including an elephant jumping up and down on it, after which it pops right back as if nothing had happened, ready for its next task.

Leader of the study, Katia Bertoldi, the John L. Loeb Associate Professor of the Natural Sciences at the Harvard John A. Paulson School of Engineering and Applied Sciences(SEAS), and colleagues say there are several potential applications for this new material.

The shape-shifting material can fold out flat and withstand the weight of an elephant, turn into a house, a window and back again, then fold out flat again – and it all fits in a person’s backpack.

The shape-shifting material can fold out flat and withstand the weight of an elephant, turn into a house, a window and back again, then fold out flat again – and it all fits in a person’s backpack.

Johannes T. B. Overvelde, a graduate student in Bertoldi’s laboratory, and first author of the study, said:

“We’ve designed a three-dimensional, thin-walled structure that can be used to make foldable and reprogrammable objects of arbitrary architecture, whose shape, volume and stiffness can be dramatically altered and continuously tuned and controlled.”

Inspiration from Snapology

The authors said they got inspiration for the new material for an origami-like technique called Snapology. The material is made from extruded cubes with thirty-six edges and twenty-four faces.

Like in origami, the Japanese art of folding paper into decorative shapes and figures, one can fold the cube along its edges to alter its shape. The scientists demonstrated both through practical experiments and theoretically that the cube can be shape-shifted into many different shapes by folding certain edges, which act like hinges.

This incredible structure can bend, fold, change volume and shape, and turn into virtually anything you want. (Image: seas.harvard.edu)

This incredible structure can bend, fold, change volume and shape, and turn into virtually anything you want. (Image: seas.harvard.edu)

No external input involved

The team embedded pneumatic actuators into the structure, which can be programmed to alter certain hinges, resulting in the cube changing shape and size, with no need for external input, i.e. it all happens internally.

Mr. Overvelde, Prof. Bertoldi, James Weaver, Senior Research Scientist at the Wyss Institute for Biologically Inspired Engineering at Harvard University, and Chuck Hoberman, of the Harvard Graduate School of Design, connected 64 of these individual cells to build a 4-by-4-by-4 cube that grows and contracts, changes shape globally, folds completely flat, and changes the orientation of its microstructure.

As the structure shape-shifts, its stiffness also changes, i.e. one can make a material that is either very stiff of pliable within the same design. The authors say that these actuated changes in the material’s properties add a 4th dimension to it.

Researchers totally control desired shape

Prof. Bertoldi said regarding getting the shape they want:

“We not only understand how the material deforms, but also have an actuation approach that harnesses this understanding. We know exactly what we need to actuate in order to get the shape we want.”

The material can continue changing into a virtually infinite number of different shapes and sizes. (Image: seas.harvard.edu)

The material can continue changing into a virtually infinite number of different shapes and sizes. (Image: seas.harvard.edu)

This material can be embedded with any kind of actuator, including thermal, dielectric, and even water.

Dr. Weaver, who heads the Wide Field Electron Optics Laboratory, commented:

“The opportunities to move all of the control systems onboard combined with new actuation systems already being developed for similar origami-like structures really opens up the design space for these easily deployable transformable structures.”

Prof. Hoberman, Lecturer in Architecture, Extensive background in design and manufacture of transformable structures, and GSD, said:

“This structural system has fascinating implications for dynamic architecture including portable shelters, adaptive building facades and retractable roofs. Whereas current approaches to these applications rely on standard mechanics, this technology offers unique advantages such as how it integrates surface and structure, its inherent simplicity of manufacture, and its ability to fold flat.”

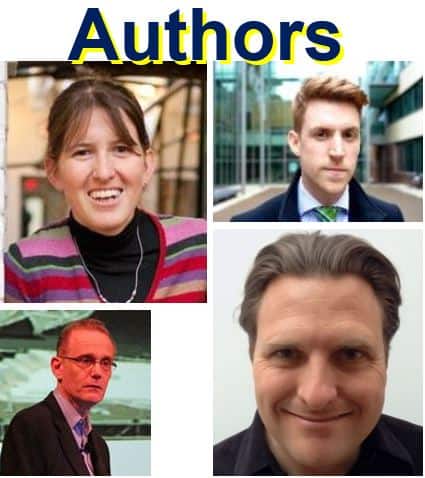

Katia Bertoldi, (top right) Johannes T.B. Overvelde, (bottom left) Chuck Hoberman, and (bottom right) James C. Weaver.

Katia Bertoldi, (top right) Johannes T.B. Overvelde, (bottom left) Chuck Hoberman, and (bottom right) James C. Weaver.

Mr. Overvelde said regarding the material:

“This research demonstrates a new class of foldable materials that is also completely scalable. It works from the nanoscale to the meter-scale and could be used to make anything from surgical stents to portable pop-up domes for disaster relief.”

The researchers made the following comment in an Abstract in the journal:

“The proposed metamaterial can be used to realize transformable structures with arbitrary architectures, highlighting a robust strategy for the design of reconfigurable devices over a wide range of length scales.”

The research was supported by the National Science Foundation, the Wyss Institute through the Seed Grant Program, and the Materials Research Science and Engineering Centre.

Reference: “A three-dimensional actuated origami-inspired transformable metamaterial with multiple degrees of freedom,” Johannes T.B. Overvelde, Sergio A. Becerra, Chuck Hoberman, James C. Weaver, George M. Whitesides, Twan A. de Jong, Yanina Shevchenko & Katia Bertoldi. Nature Communications. 11 March 2016. DOI: 10.1038/ncomms10929.

Video – Material that shift-shapes

This new Harvard invention can change shape and size amazingly rapidly.