Researchers in the Netherlands published a paper outlining a method of effectively 3D printing bacterial cultures for materials production and patterning.

The paper, authored by Benjamin A. E. Lehner, Dominik T. Schmieden, and Anne S. Meyer, describes the need for more sustainable materials production in society.

Many bacteria can carry out advanced chemical reactions to produce materials such as amyloid-based adhesives and a variety of bioplastics. However, current microbial production techniques can’t produce bespoke material structures in a reliable way.

A solution devised by the team involves coupling bacterial materials production with 3D printing technology.

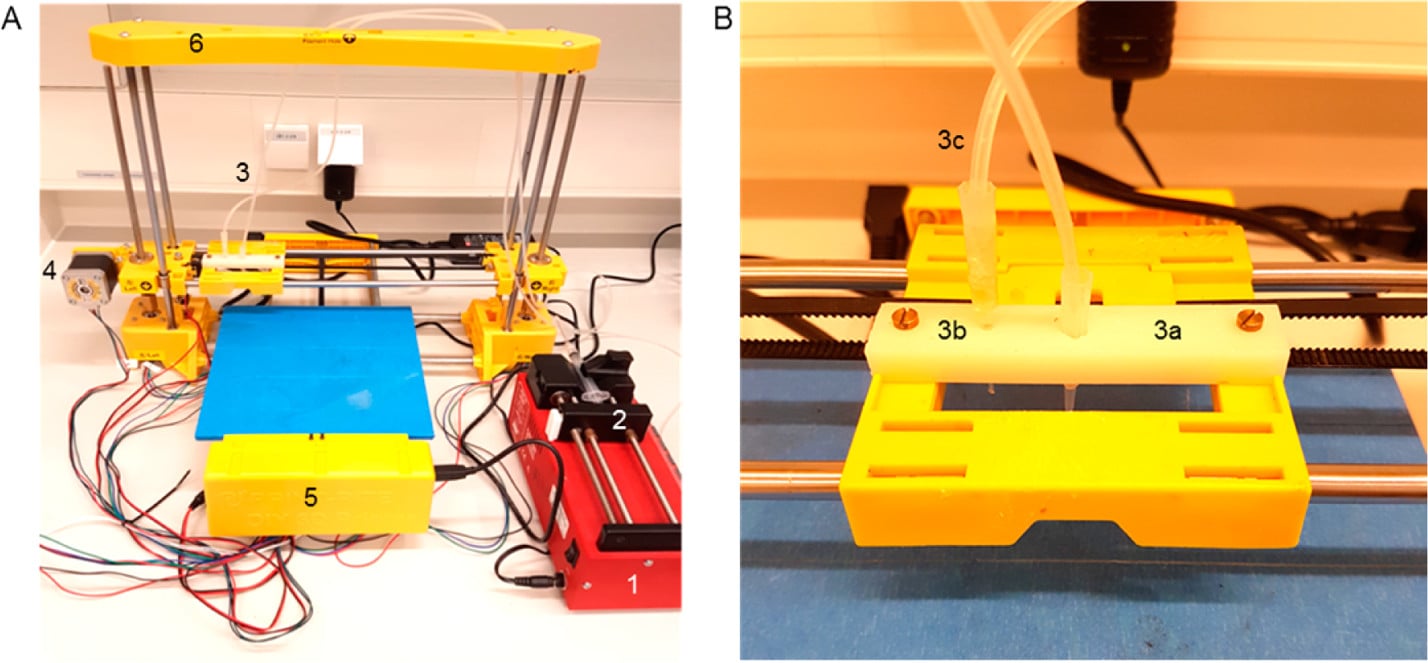

They used a modified, inexpensive, $300 USD commercial 3D printer, with the heater removed from the print-head, replaced with a liquid bacteria filled syringe and a syringe pump to control output.

The researchers explained that this alteration “allows the liquid biological ink (“bioink”) to be transported under ambient temperatures that are amenable to microbes, rather than the elevated temperatures that are applied to melt plastic filament.”

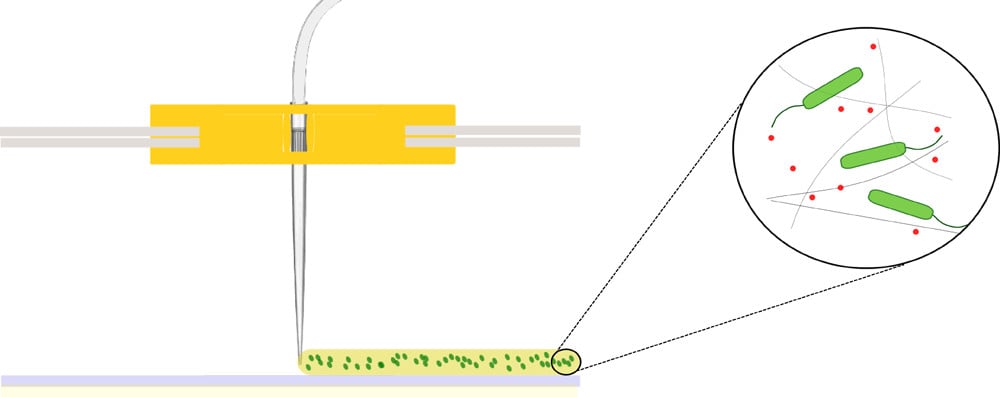

Live bacteria, when mixed with a polymer called alginate, solidifies when it touches calcium ions.

“Our printing platform uses a modified commercially available 3D printer to extrude a mixture of bacteria and alginate that solidifies into a gel upon contact with a calcium chloride-treated printing surface,” the researchers said in their report.

Survival and metabolic activity of the printed bacteria were two key factors in the demonstration of the applicability of the devised printing system.

E. coli containing the rhamnose-inducible red fluorescent protein RFP were printed onto an agar plate containing the rhamnose inducer. The gel was then incubated and monitored over a two-day period. After 8 hours of incubation the induced bioink turned red, and the color intensified after 48 hours of incubation.

“This experiment demonstrates that our printed bioink is able to support the production of bacterially made materials over short periods of time,” the researchers said.

Researchers say that in future, we will be able to make virtually anything with 3D printing technology.

Source:

Benjamin A. E. Lehner , Dominik T. Schmieden, and Anne S. Meyer, (2017) “A Straightforward Approach for 3D Bacterial Printing”, ACS Synth. Biol., DOI: 10.1021/acssynbio.6b00395