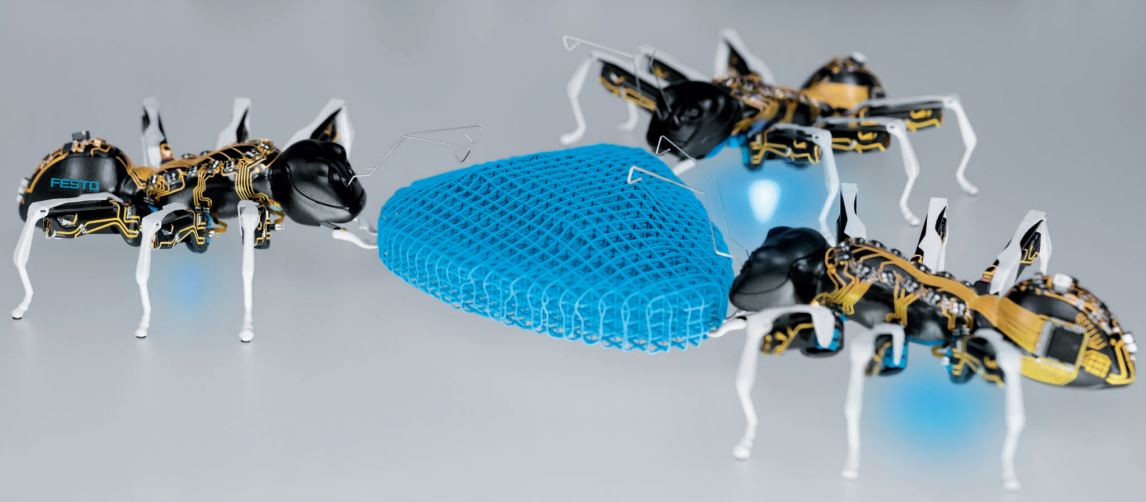

Bionic ants created by German scientists mimic the seamless teamwork of real insects by making individual decisions linked to a common group goal to get the job done. Developed by German engineering firm Festo, the human hand-sized robots they call BionicANTS, made with a 3-D printer, could eventually be used as super-efficient factory workers.

Designed for teamwork, they are able to accomplish tasks together they could never complete on their own, like transporting a large object across a surface.

“With one eye for detail and the other on the big picture: for the BionicANTs, the Festo engineers have not only taken the delicate anatomy of the natural ant as a role model. For the first time, the cooperative behaviour of the creatures has also been transferred to the world of technology using complex control algorithms.”

Festo’s BioANT looks very much like a real ant. (Image: Fento)

“Like their natural role models, the BionicANTs work together under clear rules. They communicate with each other and coordinate both their actions and movements.”

“Each ant makes its decisions autonomously, but in doing so is always subordinate to the common objective and thereby plays its part towards solving the task in hand.”

Potential as a factory worker

This cooperative behaviour, the engineers say, provides interesting approaches for the factory of the future, which will be founded on intelligent components that adjust themselves flexibly to a range of production scenarios, and thus take on tasks from a higher control level.

The BionicANTs react individually, independently to different situations, but act as an overall networked system by coordinating with one another. They can move a large object across a defined area by pulling and pushing together.

Not only is their cooperative behavior amazing, the engineers say, but also their unique production method.

The engineers wrote:

“For the first time, laser-sintered components are subsequently embellished with visible conductor structures in the so-called 3D MID process.”

“The electrical circuits are attached on the surface of the components, which thereby take on design and electrical functions at the same time.”

The BioANTS pull and push as a team and transport the object. (Image: Festo)

Wireless harmony

In this way, the technical components can all be fitted on or into the robot’s body and coordinate precisely with each other. Once all the components are activated, it is no longer necessary to control them with an external system.

However, it is still possible to monitor all the parameters wirelessly and to intervene when necessary.

The BionicANTs’ physical appearance is very close to that of their natural cousins in terms of design and constructional layout.

Even the instrument that serves as a mouth, used for grasping objects, is replicated in very accurate detail. Two piezo-ceramic bending transducers – their ‘pincers’ – are built into the jaw as actuators. “If a voltage is applied to the tiny plates, they deflect and pass on the direction of movement mechanically to the gripping jaws,” say the engineers.

Festo also uses piezo technology for the robot’s legs. Piezo elements can be controlled rapidly and very precisely – they require very little energy and do not need much space.

The BioANT is about the size of a human hand. (Image: Festo)

The engineers said regarding the robot’s legs:

“Three trimorphic piezo-ceramic bending transducers, which serve both as an actuator and a design element, are therefore fitted into each thigh. By deflecting the top bending transducer, the ant lifts its leg.”

“With the pair underneath, each leg can be exactly deflected forwards and backwards. To increase the relatively low lift, the team developed a flexible hinge joint, which extends the ant’s step size significantly.”

With its two rechargeable batteries, a BionicANT can work non-stop for forty minutes before having to link up with a charging station via its feelers.

Each ant’s movements are based on a distributed set of rules, which have been worked out beforehand using mathematical modeling and simulations which are stored in the robot.

In this multi-agent system there is no hierarchy. All the BionicANTS contribute to a task together by means of distributed intelligence.

A radio module located in the robot’s torso communicates with fellow workers. With a 3D camera fitted on to their heads, they can identify the gripping object as well as locating where they are.

“With its help, each ant is able to contextualise itself in its environment using landmarks. The opto-electrical sensor in the abdomen uses the floor structure to tell how the ant is moving in relation to the ground. With both systems combined, each ant knows its position – even if its sight is temporarily impaired,” the scientists explained.

Festo has also designed lightweight butterfly robots, which weigh just 32 grams and move about uncannily like the real insects.

Video – Robot Ants

In this Festo video you can see three BioANTs working together to move an object across a surface.