A team of researchers has created a 3D-printed glucose biosensor. The glucose biosensor is for use in wearable monitors, say scientists from Washington State University. They add that their work may lead to better glucose monitors for millions of diabetes patients globally.

Arda Gozen, Yuehe Lin and colleagues wrote about their research in the journal Analytica Chimica Acta (citation below). Gozen is an Assistant Professor at Washington State’s School of Mechanical and Materials Engineering. Lin is a Laboratory Fellow, also at the School of Mechanical and Materials Engineering.

Each diabetes patient today uses a glucose biosensor to monitor their blood glucose levels. Patients have to prick their finger constantly. Continuous glucose monitoring systems are also possible. However, these alternative systems are costly.

3D printing technology refers to printers that can create three-dimensional objects.

Creating a wearable glucose biosensor

Scientists have been trying to develop wearable, flexible electronic devices that conform to patients’ skin. These devices would monitor the glucose in patients’ sweat and other bodily fluids.

To create such a glucose biosensor, manufacturers have used screen printing, photolithography, and other traditional manufacturing practices.

Even though these methods work, they come with several drawbacks. For example, they require the use of expensive clean-room processing. They also require the use of harmful chemicals.

In this latest research, scientists used 3D printing to create a glucose biosensor with much better stability and sensitivity compared to those currently manufactured through traditional methods.

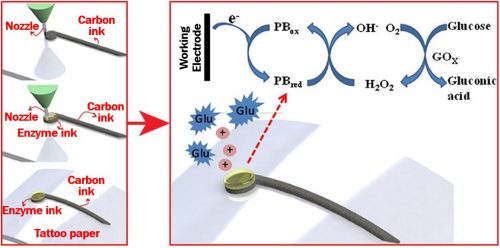

The graphic above shows the 3D-printed glucose biosensor. It also illustrates the direct-in-writing of electrode and enzyme ink. (Image: https://s3.wp.wsu.edu)

Using DIW to create a glucose biosensor

The scientists used DIW or direct-ink-writing to create a glucose biosensor. With DIW, the printer prints inks’ out of nozzles to create precise and intricate designs at tiny scales.

The authors printed out a nanoscale material that is electrically conductive to create flexible electrodes. Their technique allows a precise application of the material, which results in a uniform surface. The surface has significantly fewer defects. This increases the sensitivity of the sensor.

The researchers found that their 3D-printed glucose sensor was more sensitive than traditionally produced electrodes. In other words, they were better at picking up glucose signals.

Creating a customizable glucose biosensor

Thanks to 3D printing, their system is also more customizable. This means they can custom-make each glucose biosensor according to people’s biology.

Prof. Gozen said:

“3D printing can enable manufacturing of biosensors tailored specifically to individual patients.”

3D-printing also uses the exact amount of material required. Therefore, there is less waste compared to traditional manufacturing methods. “This can potentially bring down the cost,” said Prof. Gozen.

In an Abstract that precedes the main article in the journal, the authors wrote the following regarding their glucose biosensor: “The first 3D printed flexible electrochemical biosensor for glucose detection.”

For large-scale usage, the printed glucose biosensors will have to be integrated with electronic components on a wearable platform.

However, the same 3D printer nozzles could be used by the manufacturers for printing the sensors to print electronics and other components on a wearable medical device. This would help consolidate manufacturing processes. It would also reduce costs further, Prof. Gozen added.

Dr. Lin said:

“Our 3-D printed glucose sensor will be used as a wearable sensor for replacing painful finger pricking. Since this is a noninvasive, needleless technique for glucose monitoring, it will be easier for children’s glucose monitoring.”

The researchers are currently working to integrate the sensors into a packaged system. Patients would be able to wear the device like an item of clothing. They would use it for long-term glucose monitoring.

Many hi-tech companies, including Apple Inc., have invested in wearable medical devices.

Citation

“Micro additive manufacturing of glucose biosensors: A feasibility study,” Yuehe Lin, Sepehr Nesaei, Yang Song, Arda Gozen, Yijia Wang, Dan Du, and Xiaofan Ruan. Analytica Chimica Acta, Volume 1043, 28 December 2018, Pages 142-149. DOI: https://doi.org/10.1016/j.aca.2018.09.012.