In today’s commercial spaces, environmental responsibility and durability are two important factors when choosing the floor. SPC(Stone Plastic Composite) floors are popular due to their high resistance to wear and low upkeep requirements. Moreover, such materials decrease long-term costs and energy consumption. Compared to wood floor, SPC floor is a better choice; keep reading and you will know why!

What is SPC Flooring?

SPC, or Stone Plastic Composite flooring, is a rigid-core luxury vinyl product for durability and dimensional stability. Its multi-layer structure has a wear layer, a printed vinyl layer, a rigid SPC core, and an underlayment.

The core layer is a composite of limestone powder and thermoplastics, it separates the SPC floor from traditional vinyl or WPC flooring for resistance to impacts and temperature fluctuations. This renders it impervious to water, which benefits basements, kitchens, or commercial settings. Furthermore, the dense core provides sound insulation.

Also, its thermal stability is compatible with radiant heating systems, which is a consideration in cold climates. SPC does not expand or contract as much as wood or laminate due to its inert nature. So it doesn’t need acclimation before installation. Finally, its UV resistance gives the surface design stability over time. Hence, SPC flooring suits residential and high-traffic commercial settings.

Why SPC Flooring Outperforms Wood Flooring

Durability and Resistance to Wear and Tear

SPC floor offers durability due to its multi-layer construction. Unlike wood flooring, which may suffer dents and scratches from heavy foot traffic, the SPC floor includes a rigid limestone core and stabilizers to resist impact and abrasion.

The top wear layer with UV coatings protects against scratches and stains. The SPC floor’s dense core also prevents it from warping or expanding. It is an issue seen in wood under fluctuating temperatures. Unlike hardwood, SPC floors are long-lasting for high-traffic or commercial settings that endure wear without repairs or refinishing.

Water Resistance and Suitability for Various Environments

In water resistance, the SPC floor outperforms wood. While wood absorbs moisture to swell, warp, or rot over time, the SPC floor is 100% waterproof due to its core composition. It suits kitchens, bathrooms, or basements. SPC flooring provides an advantage for climates susceptible to wet or humid conditions.

Ease of Installation and Maintenance

SPC floor installation is simplified through click-lock systems, which don’t need nails or adhesives. It saves floating installations time and effort than wood flooring, which may entail gluing or nailing for engineered wood or solid hardwood.

After installation, maintenance of the SPC floor is also frank. It resists staining and obliges only basic cleaning. It differs from wood, which needs polishing, refinishing, and cleaning to avoid water damage. Further, the SPC floor’s resilience to dents and scratches cuts ongoing maintenance for commercial uses.

Cost-Effectiveness and Long-Term Value

Regarding the lifecycle costs, SPC flooring is more cost-effective than wood flooring. While the upfront cost of high-end wood flooring can be prohibitive, SPC floor is priced lower for premium options without losing performance.

Additionally, SPC’s low maintenance and high durability lower future expenditures on repairs or refinishing. Yet, wood floors may demand refinishing after a few years in high-traffic areas and can cause damage that requires repairs. For long-term value, the SPC floor delivers a dependable return on investment with negligible ongoing costs.

Aesthetic Versatility and Design Options

Though wood flooring is traditionally aesthetic, SPC flooring now rivals it in design flexibility. Printing technology can allow SPC floors to replicate natural wood, stone, or ceramic with higher practicality than older vinyl products.

Apart from that, unlike stained wood, which may lose its luster, SPC flooring offers more colors, textures, and finishes that won’t fade or wear down over time. It lets homeowners and designers accomplish specific design outcomes, including rustic and contemporary styles, and benefit from the performance of SPC flooring.

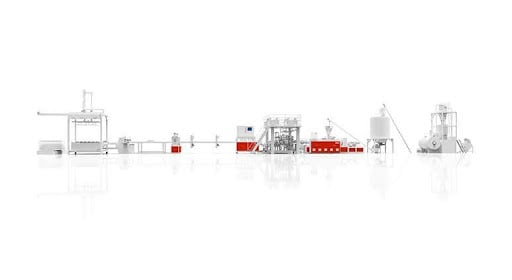

Boyu’s SPC Production Line: The Smart Business Choice

As an experienced flooring manufacturer, Boyu’s SPC flooring production line satisfies all your needs. Whether parallel or conical twin screw extruder, Boyu utilizes high-quality CE-certificated machines you can trust. Besides, all these machines are PLC programmed and equipped with a touchscreen interface, ensuring high precision during the whole floor production process.

Boyu offers different equipment models that are tailored to different customer needs. Especially the new SPC180 model of efficiency and reliability: It has a gigantic capacity of 70-100 tons per 24 hours, which is 3 times larger than the 110 model, but at the same time saves more energy, saves plant place and saves labor.

What’s more, their unique Synchronized floral pattern technology (EIR patents) helps produce more wooden-like SPC floors. With stable performance and a low failure rate in every step, Boyu is definitely your best choice

Conclusion

Boyu provides precision-engineered SPC flooring systems that distribute homogeneous raw materials, better filtration, and high surface polish. Their equipment meets the need for durable, high-quality flooring with over 90 patents and a worldwide presence. Their development satisfies market demands for manufacturing consistency and performance. So, why wait? Visit Boyu’s website now!