At their core, linear motion actuators are devices that generate force and motion in a straight line, usually in the form of pushing or pulling movements. Unlike rotational motion, which revolves around an axis, linear motion has a straightforward trajectory.

In today’s dynamic business landscape, these actuators have become indispensable. From the factory floors of automated manufacturing plants to the precise adjustments in high-tech medical devices, linear motion actuators play a pivotal role in optimizing operations, ensuring precision, and, most importantly, driving growth. Such leading manufacturer as Progressive Automations knows everything about future trends and needs appearing in diverse industries.

Basics of Linear Motion Actuators: Definition and Main Components

A linear motion actuator is a mechanical device that produces linear movement from a source of energy. Typically powered by electric motors, hydraulics, or pneumatic systems, these actuators come equipped with various components, such as:

- Drive Mechanism: This can be a screw, belt, or linear motor that transforms rotational motion into linear motion.

- Guidance System: Rails or guides ensure that the motion is strictly linear, preventing any unwanted sideways or rotational movements.

- Positioning System: Sensors and encoders that provide feedback on the actuator’s position, enabling precise control.

- Principles of Operation: The operation of a linear motion actuator is fundamentally based on converting energy into linear movement. For electric linear actuators, when power is applied to the motor, it rotates. This rotational movement is then converted to a linear motion through the drive mechanism. For example, in a screw-driven actuator, the rotation of the screw results in the linear movement of a nut along the screw’s shaft. This motion, combined with the guidance system, ensures the actuator moves in a straight line. The positioning system continually monitors this movement, ensuring the desired position is achieved and maintained with high precision.

Key Industries Benefiting from Linear Motion Actuators

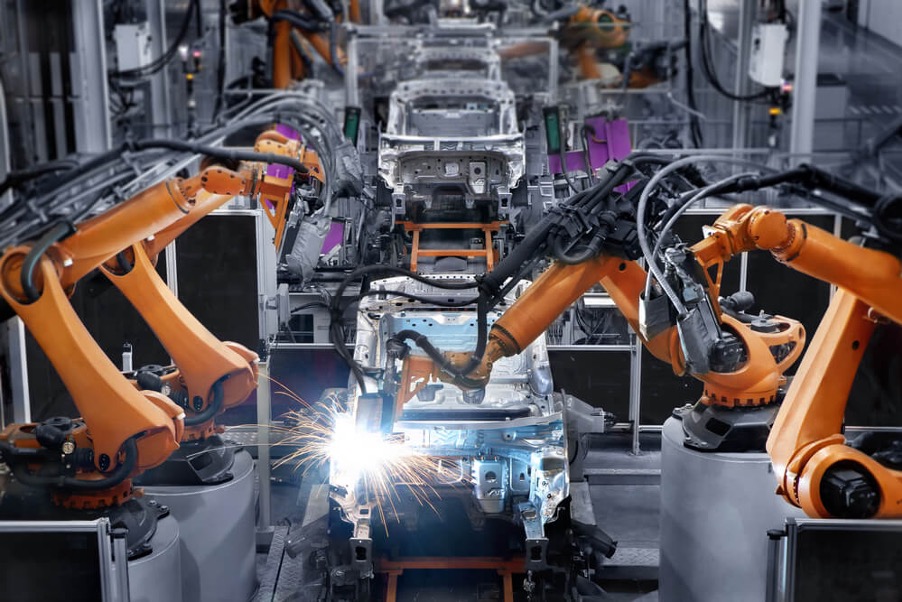

Manufacturing and Automation: In modern manufacturing facilities, precision, speed, and reliability are paramount. Linear motion actuators facilitate these by providing precise control in tasks like assembly line positioning, pick-and-place operations, and CNC machine operations. Automated systems, with the help of actuators, have transformed traditional manufacturing into a faster, more consistent, and more efficient endeavor.

Healthcare: The medical world requires unparalleled accuracy, especially when human lives are at stake. Actuators in medical devices, like surgical robots or MRI machines, enable movements that are both precise and controlled. They play a role in administering treatments, conducting diagnostic tests, and even aiding complex surgeries, ensuring patient safety and enhanced outcomes.

Aerospace and Defense: In the realm of aerospace and defense, actuators have multiple applications—from controlling the wings of an aircraft to the precise positioning of satellite dishes in space. They ensure that missiles are launched accurately, drones fly correctly, and defense mechanisms operate as intended, thereby playing a crucial role in national security and space exploration.

Automotive: Modern cars are marvels of automation and precision. Actuators in vehicles control everything from adjusting seats and mirrors to the intricate operations in automated assembly lines. As vehicles become more advanced, with features like self-parking and advanced driver assistance systems, the role of actuators becomes even more integral.

Others: Other industries, such as entertainment (for motion simulation in virtual reality setups), agriculture (for automated farming equipment), and logistics (for warehouse automation), also heavily rely on linear motion actuators to bring about efficiency and innovation.

Business Advancement Opportunities Created by Linear Motion Actuators

Enhanced Precision in Tasks: The primary advantage of actuators is the ability to achieve unparalleled accuracy. Whether it’s placing a microchip on a circuit board or guiding a surgical robot, the precision offered by actuators ensures tasks are executed flawlessly.

Increased Efficiency and Speed of Operations: Actuators, being automated, can operate continually without the need for breaks. This non-stop operation, combined with their speed, ensures that tasks get completed in a fraction of the time compared to manual processes.

Greater Reliability and Consistency: Machines don’t suffer from fatigue or inconsistency. Linear motion actuators, once set, will perform their tasks consistently, reducing the variability seen in manual operations and ensuring products or outcomes of consistent quality.

Cost Savings: Though there’s an initial investment in integrating actuators, the long-term benefits are substantial. Automated processes lead to reduced manual labor costs. Additionally, the precision and consistency of actuators minimize errors, leading to fewer defects, reduced waste, and lower costs in rectifications.

As technology advances, linear motion actuators are anticipated to become even more compact, efficient, and adaptable. Emerging technologies, such as AI-driven predictive maintenance and advanced materials, will seamlessly integrate with actuators, enhancing their performance and lifespan. These innovations in actuator technology are poised to redefine operational efficiency across diverse sectors, driving the next wave of business transformation and industry growth.

Actuators are, without a doubt, transforming industries and creating opportunities for businesses to excel. As technology continues to evolve, its role will only become more pronounced, setting the stage for a more efficient, precise, and innovative future.

Interesting Related Article: “Application of Linear Actuators in the Aerospace Industry“