An American manufacturer that makes transparent coatings for glass has begun developing see-through electricity-generating veneers that can be fitted onto existing windows to convert them into solar panels.

SolarWindow Technologies of Columbia, MD, estimate the market for its product to be over 430 million square feet of windows in the U.S. alone.

The electricity-generating windows could turn skyscrapers into vertical power generators, potentially reducing electricity costs by up to 50% per year. Image: SolarWindow

The electricity-generating windows could turn skyscrapers into vertical power generators, potentially reducing electricity costs by up to 50% per year. Image: SolarWindow

The company envisions a system where the veneers they are developing have an innovative fastening system on one side and a transparent electricity-generating coating on the other.

These can be applied directly onto existing windows of homes and commercial buildings. The idea is installers cut them to size and fit them on site.

Fitting such a veneer onto an existing “passive” window transforms it into an “active” power-generator that captures solar energy and converts it into electricity.

The electricity generated in the active windows can be routed into the building’s electrical system, or even connected directly to fixtures for use.

Five million skyscrapers

There are five million tall skyscrapers in the U.S. that consume nearly 40 percent of the country’s total generated electricity, say SolarWindow.

The company is already developing electricity-generating liquids that can be coated onto newly-manufactured glass as it is made into a window.

The system essentially converts a building into a vertical power generator, with the potential to reduce the annual cost of electricity by up to 50 percent.

Using their own, independently validated power and financial model, SolarWindow reckon a 50-story building can produce 50 times more energy from their electricity-generating windows than a rooftop solar panel system.

Plus, they say the SolarWindow system for such a building would pay for itself within a year, and reduce carbon dioxide emission equivalent to 770 acres of forest sequestering carbon dioxide.

Coatings technology

The firm has already developed proprietary, patent-pending, electricity-generated liquid coatings that can be applied to new glass during manufacture.

Earlier this year, they released high-powered microscope images of their coatings technology.

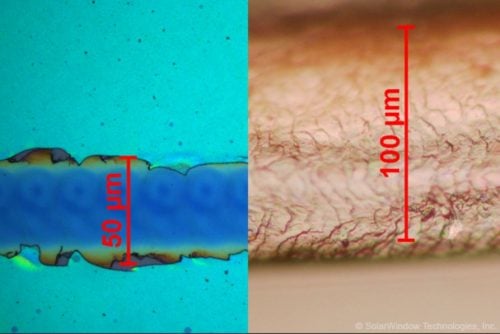

The microchannels are thinner (50 micrometers, on the left) than human hair (typically 100 micrometers, on the right). Image: SolarWindow

The microchannels are thinner (50 micrometers, on the left) than human hair (typically 100 micrometers, on the right). Image: SolarWindow

The technology comprises a grid of microscopic channels about 50 micrometers thick – about half the width of a human hair. These are embedded in ultra-thin layers of electricity-generating coatings.

More traditional approaches rely on components that are as much as ten times thicker and use chemical or mechanical systems, which can be slow, unreliable, and prone to wear and tear.

Also, being at a larger scale, the more traditional systems’ channels are highly visible, not pleasing to look at, and yield poor electron flow.

The technology is based on a barely visible grid of microchannels embedded in ultra-thin layers of electricity-generating coatings. Image: SolarWindow

The technology is based on a barely visible grid of microchannels embedded in ultra-thin layers of electricity-generating coatings. Image: SolarWindow

In the SolarWindow system, electricity moves inside the coating to the grid of microchannels, or “invisible wires” as the company calls them.

The wires then transport the electricity across the surface to the edge of the glass, where it is connected to the building’s electrical systems.

SolarWindow say their proprietary approach, which does not rely on chemical and mechanical systems, not only ensures a smooth, efficient pathway for the flow of electricity, but also “enables continuous, high-speed, high-volume manufacturing.”