Scientists have created a fabric alternative to batteries for wearable electronics. The researchers, from the University of Massachusetts at Amherst, have developed a method for making a charge-storing system. It is easy to integrate the system into clothing for “embroidering a charge-storing pattern onto any garment,” they say.

Lushuai Zhang, Wesley Viola, and Trisha L. Andrew wrote about their work in the journal ACS Applied Materials & Interfaces (citation below).

The main obstacle holding back the development of wearable biosensors is the lack of a long-lasting power supply that is lightweight. This is especially the case in the development of wearable electronics for health monitoring.

Team leader, Andrew, a materials chemist who directs the Wearable Electronics Lab at UMass Amherst, explains:

“Batteries or other kinds of charge storage are still the limiting components for most portable, wearable, ingestible or flexible technologies. The devices tend to be some combination of too large, too heavy and not flexible.”

Wearable electronics – high ability to store charge

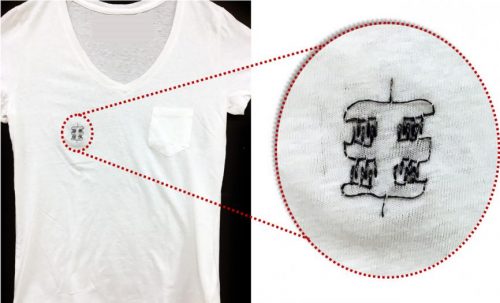

The scientists’ new method uses a micro-supercapacitor and combines a polymer film with vapor-coated conductive threads. They also use a special sewing technique to create a mesh of aligned electrodes which they position on a textile backing.

The solid-state device they have created has a high ability to store electricity for its size. It also has other features that allow it to power wearable biosensors.

Researchers have made huge advances in miniaturizing different electronic circuit components. However, this has not been the case for charge-storing devices.

Leading online clothing stores such as Tom Murphy Menswear are investing in wearable electronics for the future market.

Sewing circuits onto self-powered smart garments

Andrew said:

“With this paper, we show that we can literally embroider a charge-storing pattern onto any garment using the vapor-coated threads that our lab makes. This opens the door for simply sewing circuits on self-powered smart garments.”

The researchers pointed out that supercapacitors are ideal candidates for wearable charge storage. Compared to batteries, they have inherently higher power densities.

However, the authors add:

“Incorporating electrochemically active materials with high electrical conductivities and rapid ion transport into textiles is challenging.”

The researchers showed that their vapor coating process created porous conducting polymer films on densely-twisted yarns. They can be easily swelled with electrolyte ions. They also maintain high charge storage capacity per unit length as compared with prior studies with extruded or dyed fibers.

Using vapor deposition – costs

High costs and technical difficulties have prevented most scientists from using vapor deposition, Andrew explains. However, more recent studies have shown that it is possible to scale up the technology, thus improving its cost-effectiveness.

The research team is currently working with other scientists at the UMass Amherst Institute for Applied Life Science’s Personalized Health Monitoring Center. They are working on incorporating the new, embroidered charge-storage arrays with low-power microsensors and e-textile sensors to build smart garments.

These smart garments will monitor people’s joint movements and gait throughout a normal day.

What are wearable electronics?

The term ‘wearable electronics’ refers to technology that we can wear. We also use the terms wearables, wearable devices, and wearable technology.

Cyrcadia Health’s iTBra, for example, is a wearable electronics item. It is effective at detecting breast cancer early. The Hex, which gives athletes real-time data on their muscles’ levels of oxygen, is also a ‘wearable.’

Citation

“High Energy Density, Super-Deformable, Garment-Integrated Microsupercapacitors for Powering Wearable Electronics,” Lushuai Zhang, Wesley Viola, and Trisha L. Andrew. ACS Applied Materials & Interfaces 2018, 10 (43), pp 36834–36840. DOI: 10.1021/acsami.8b08408.