Failure mode refers to how a device, equipment, or machine can fail. If there are several potential ways that something can go wrong, we say that it has multiple failure modes. We can also use the term ‘competing risks.’

A burglar alarm, for example, does not have just one failure mode. It can fail as a result of a defective motion or heat sensor, faulty alarm, or a wiring problem. A missing, faulty, or dead battery may also be the cause of the alarm’s malfunction.

Therefore, a burglar alarm has multiple failure modes or competing risks.

Failure mode, cause, effect

‘Mode,’ ’cause,’ and ‘effect,’ when used with the word ‘failure,’ have different meanings.

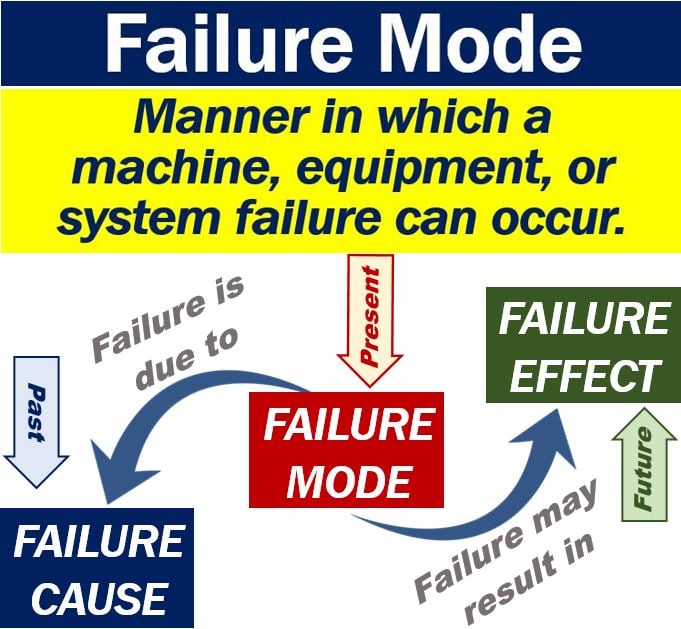

- When we are focusing on the present, we use failure mode.

- Failure cause describes why a failure happened, i.e., it focuses on the past.

- Failure effect is all about the consequences of the failure, i.e., it focuses on the future.

Example

Let’s imagine that a bird flew high up in the air and crashed into an airplane’s jet engine. The engine caught fire, stopped functioning, and the aircraft had to make an emergency landing.

Fortunately, an experienced pilot was in control, and the plane landed successfully. However, one passenger broke a leg while another developed severe back pains.

Failure mode describes the engine shutting down and triggering an emergency landing. Failure cause describes why the engine shut down, i.e., the bird flying high and crashing into the engine.

Failure effect tells us about the injuries and health problems that the passengers suffered.

We describe how we observe a failure in ‘failure mode.’ The failure is due to the ‘failure cause,’ and may lead to the ‘failure effect.’

Physical/abstract failure modes

Not only do we use the term for physical things, i.e., things we can touch, but also abstract things.

We cannot touch abstract things because they have no physical form, i.e., we can only think about them. Systems, such as management or computer software systems, for example, are abstract

When we say ‘a failure mode,’ we are talking about one cause of failure. In other words, one possible way something can fail.

Corrosionpedia.com has the following definition of the term:

“A failure mode is a manner in which an equipment or machine failure can occur. It is the basic material behavior that results in failure.”

Using the term in its plural form, i.e., failure modes, is also common.

Failure mode – common ones

Below is a list of some of the most common failure modes:

- Premature operation.

- The user did not operate the machine, for example, at the right time.

- The user did not cease operation at the right time.

- Something went wrong while the machine was in operation.

- There was a degradation in the machine’s capability.

- It is also possible that somebody overused it, i.e., pushed it too hard.

According to Corrosionpedia.com, corrosion is an example of a failure mode. Corrosion may cause failure due to metal degradation.

Failure mode and effects analysis

FMEA-FMECA.com says “failure modes are a key ingredient to a Failure Mode and Effects Analysis (FMEA).”

Reliability engineers in the late 1950s developed FMEA. It was one of the first highly structured systematic techniques for failure analysis. They developed FMEA to study problems that military systems might have.

Failure analysis is the investigation into how something failed, why it failed, and how to correct it. It also includes suggesting how to make sure the failure does not happen again.

In a system reliability study, an FMEA is often the first step. Wikipedia says the following regarding an FMEA:

“It involves reviewing as many components, assemblies, and subsystems as possible to identify failure modes, and their causes and effects.”

“For each component, the failure modes and their resulting effects on the rest of the system are recorded in a specific FMEA worksheet.”

An FMEA may exist as a process, design, or functional analysis. When an FMEA includes a critical analysis, we call it an FMECA (failure mode, effects, and criticality analysis).