Failure mode and effects analysis or FMEA is a step-by-step approach to identifying every potential failure in something. We can use the term for machines, equipment, services, systems, and processes. In other words, we can use the approach for physical and abstract things. We can touch physical things, i.e., they have physical form. It is impossible for us to touch, see, or smell abstract things; we can only think about them.

Failure mode is a description of the manner in which a failure happened or can happen.

Failure cause looks at why something happened, while failure effects looks at the consequences of the failure.

Therefore, failure mode, failure cause, and failure effects, focus on the present, past, and future respectively.

In other words, it is an approach that looks at each failure and each one’s knock-on effect. Then we view them all together to get a better idea of the overall consequences.

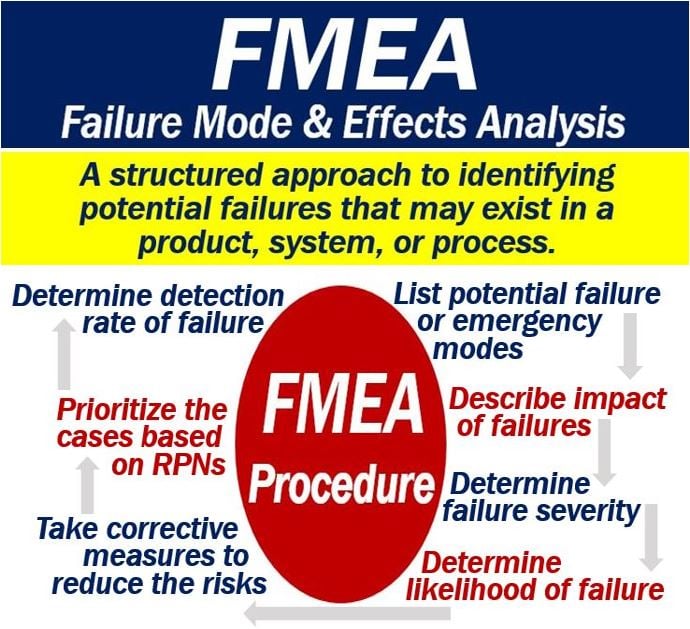

When carrying out an FMEA, there is a procedure that the analyzers must follow. RPN stands for Risk Priority Number. (Data Source: adapted from slideshare.net/GRFDavos)

Failure analysis

FMEA dates back to the 1950s. It was one of the first highly structured systematic techniques for failure analysis.

Reliability engineers wanted to study problems that could arise when military systems malfunctioned.

After something fails, companies may order an investigation into why it happened and how to correct it. We call that investigation a ‘failure analysis.’

FMEA – prioritizing failures

When we carry out an FMEA, we prioritize failures according to their consequences. In other words, we list them according to how serious their consequences are.

Often, we also prioritize them according to how frequently they occur and how easily we can detect them.

The main purpose of any FMEA is to be able to take corrective actions, i.e., reduce future risk as much as possible. The best way to do this is to focus on the highest-priority failures first.

ASQ.org says the following regarding the term:

“Failure modes and effects analysis also documents current knowledge and actions about the risks of failures, for use in continuous improvement.”

“FMEA is used during design to prevent failures. Later it’s used for control, before and during ongoing operation of the process.”

FMEA – when to use

FMEAs are useful for many different purposes and situations. Below is a list of their most common uses:

- After quality function deployment, when we are designing or redesigning something.

- When we plan to use or apply something in a new way. It could be a product, service, process, or system. It already exists, but we have never used it in this new way before.

- Before we develop control plans for something that is new or something that we have modified.

- When we have specific improvement goals for an existing system, service, process, or product.

- When trying to analyze failures for an existing system, service, process, or product.

- As standard practice, we should perform an FMEA periodically, i.e., a number of times during its life.

Types of FMEAs

There are also several different types of FMEAs, such as functional, process, and design FMEAs.

When the study also includes a ‘criticality analysis,’ we call it an FMECA. FMECA stands for Failure Mode, Effects, and Criticality Analysis.