A focused factory is a factory that its creators have organized around a very specific set of resources. The focus of this type of factory is very narrow, i.e., it provides a narrow range of operations. The vast majority of focused factories are mass production facilities.

In this article, the word ‘facility’ means the same as ‘factory.’

The creators of a focused factory wanted it to make a very narrow range of products at minimal costs. They designed the production facility so that it would have a high rate of throughput.

Focused factory – fixed assets

A typical focused factory has a significant fixed asset base. It also produces at extremely high volume, i.e., it mass-produces things.

If its owner doesn’t have it producing a lot, it will be running at a loss. This is because this type of factory has relatively large fixed costs. Therefore, it needs a relatively high production rate just to break even.

Fixed costs are costs that do not fluctuate each month, i.e., they are always the same. Fixed costs contrast with variable costs. Rent, for example, is a fixed cost.

Flexible vs. focused factory

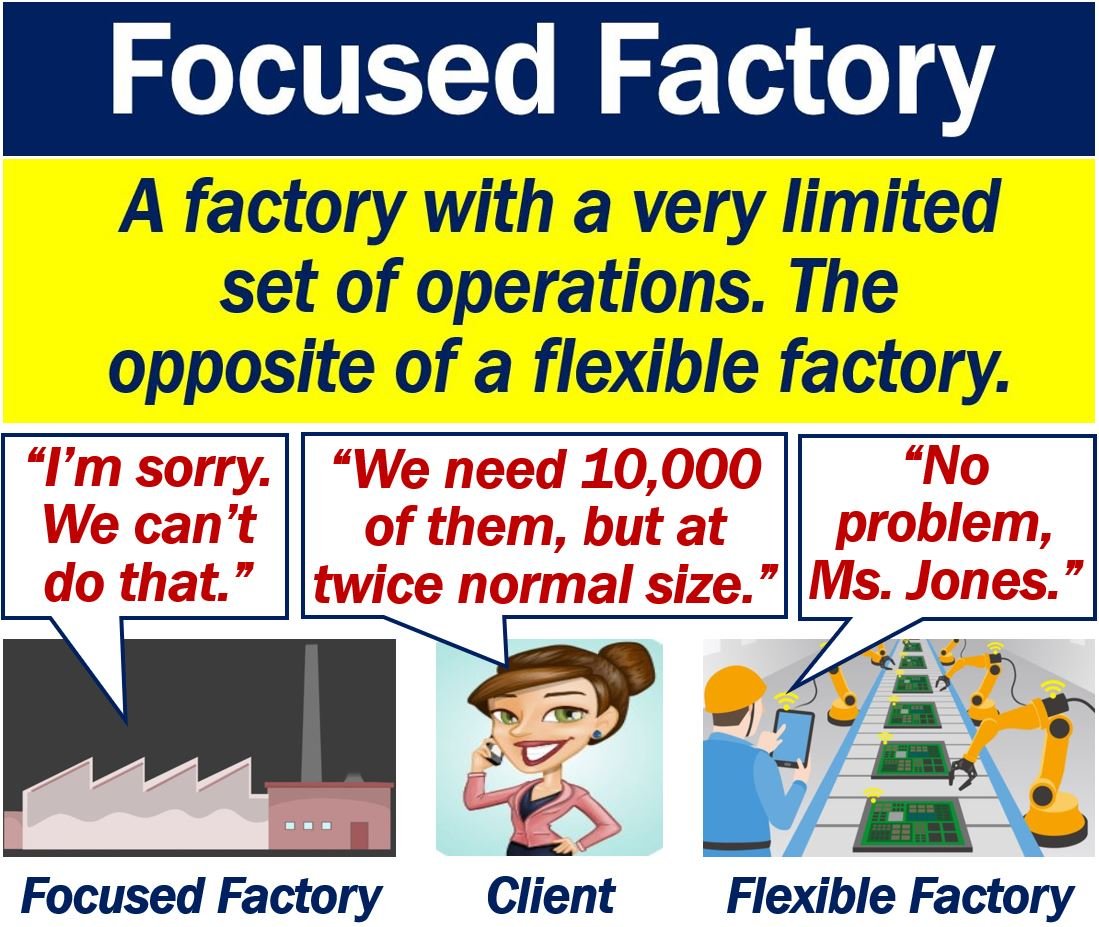

The focused factory contrast with the flexible factory. Flexible factories are production facilities that can rapidly configure to produce a wide range of products.

Flexible factories, unlike focused ones, can change what they produce at relatively short notice. Hence, we call them ‘flexible.’

The creators of flexible factories deliberately designed them so that they could provide a wide range of operations. Put simply; flexible factories have short changeover times and can operate across different product lines.

Focused factory – Wickham Skinner

Wickham Skinner first used the term ‘focused factory’ in a May 1974 issue of the Harvard Business Review.

He wrote the article in the same year he became the James E. Robinson chair in Business Administration at the Harvard Business School. He is now the Emeritus James E. Robinson Professor of Business Administration at the Harvard Business School.

In the article, Prof. Skinner wrote that the conventional factory attempted to carry out too many conflicting tasks. It tried to do them within just one inconsistent set of manufacturing policies.

When it tried to do too many things, it became non-competitive. It became non-competitive because its policies were not focused on one key manufacturing task. Its one task was to compete with its industry, Prof. Skinner explained.

Regarding a focused factory, Prof. Skinner wrote:

“A factory that focuses on a narrow product mix for a particular market niche will outperform the conventional plant, which attempts a broader mission.”

“Because its equipment, supporting systems, and procedures can concentrate on a limited task for one set of customers, its costs and especially its overhead are likely to be lower than those of the conventional plant.”

However, more importantly, Prof. Skinner added, a focused factory can become a competitive weapon.

It can become a competitive weapon because it completely focuses on accomplishing a particular manufacturing task. A task that the company’s overall strategy and marketing objective demand.