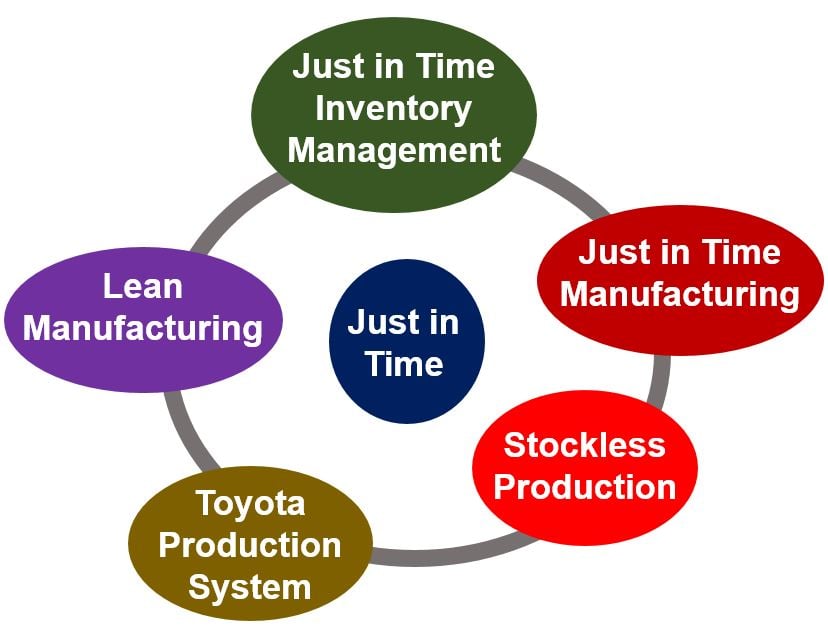

Just in Time is often referred to as Just in Time Manufacturing, Just in Time Production, Just in Time Inventory Management, Lean Manufacturing, Stockless Production, or the Toyota Production System. It is an inventory system that does away with large stocks. Businesses can switch to an alternative method of stock control which minimizes spending and boosts competitiveness.

With ‘just in time,’ a company holds virtually no stocks. Instead, it relies on the prompt deliveries of components and raw materials. They must arrive the moment the company requests them.

Rather than occasional major deliveries to a warehouse, in a just in time system supplies arrive only when the company asks for them. The producer subsequently takes them to the factory floor immediately.

This system contrasts with ‘Just-in-Case,’ an inventory management strategy that businesses use when they store huge amounts of inventory. Companies use Just-in-Case because they do not want to run out of stock. Make-to-stock has a similar meaning to just-in-case.

Companies that follow a make-to-order manufacturing system have minimum stock levels. They wait for a customer’s order to come in before making the finished product.

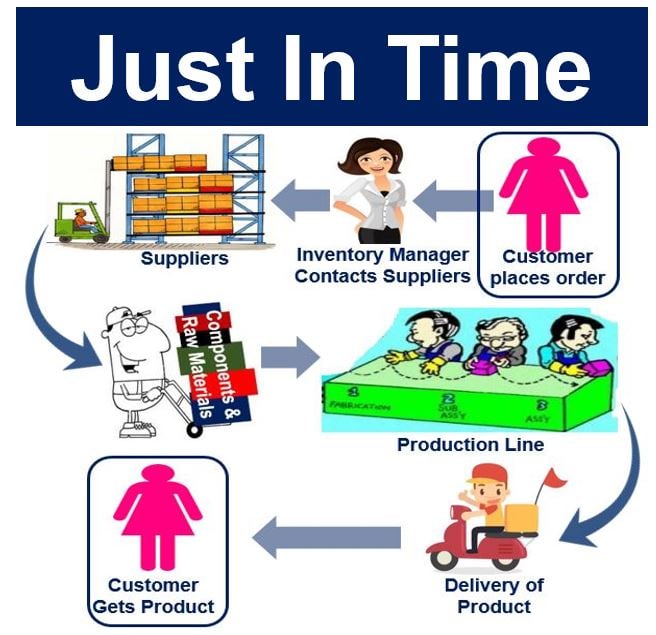

As this image shows, as soon as the inventory manager gets an order, she makes sure the suppliers are informed. The supplies go straight to the factory floor, where production occurs. It is then delivered to the customer. Just in time inventory management involves keeping stocks to a minimum at all times.

As this image shows, as soon as the inventory manager gets an order, she makes sure the suppliers are informed. The supplies go straight to the factory floor, where production occurs. It is then delivered to the customer. Just in time inventory management involves keeping stocks to a minimum at all times.

Just in time reduces warehouse costs

The technique is only advantageous for the company when the reduced warehouse costs more than make up for the lost purchasing economies of scale from the bulk-buying of components and raw materials and more frequent deliveries.

The Institute for Manufacturing at the University of Cambridge in England made the following comment regarding just in time:

“Just in time is a management philosophy and not a technique. It originally referred to the production of goods to meet customer demand exactly, in time, quality and quantity, whether the ‘customer’ is the final purchaser of the product or another process further along the production line.”

“It has now come to mean producing with minimum waste. ‘Waste’ is taken in its most general sense and includes time and resources as well as materials.”

This approach clashes with the traditional notion that all companies should aim for a 100% fill rate. Fill rate is the percentage of customer orders that a company can deliver from stock at hand.

Toyota – the just in time pioneer

Automaker giant Toyota first adopted the system in the 1960s, along with Heijunka. Experts say it was in response to a lack of cash in post-WWII Japan. While the country was rebuilding its industry, money was tight.

Japan also lacked space to create giant factories full of inventory. Japanese industry had to ‘lean out’ its processes. In other words, it aimed for smaller factories and warehouses, and minimum inventory levels.

‘Just In Case’ functions as a push system. The company stocks up its inventory as much as it can. ‘Just in Time’ is a pull system. In other words, it allows for demand to set the tone of production. ‘Pull’ is made to order, while ‘Push’ is made for inventory.

‘Just In Case’ functions as a push system. The company stocks up its inventory as much as it can. ‘Just in Time’ is a pull system. In other words, it allows for demand to set the tone of production. ‘Pull’ is made to order, while ‘Push’ is made for inventory.

JIT only began to have an impact in the Western world in the late 1970s. Even then, the pioneers in North America and Western Europe used several different terms.

Hewlett Packard, for example, referred to it as ‘stockless production.’ The term ‘lean manufacturing’ also became popular.

In a Brunel University paper, J. E. Beasley made the following comment:

“One often reads nowadays that JIT involves employee participation, involving workers so as to gain from their knowledge and experience. Such participation is meant to ensure that workers feel involved with the system and make suggestions for improvements, cooperate in changes, etc.”

“Personally I am not convinced that this aspect of JIT, as it is interpreted nowadays, played any part in its initial development.”

Just in time – forecasting demand

For JIT manufacturing to work successfully, producers need to be able to forecast demand accurately.

Today, many car manufacturers across the world operate at varying degrees of JIT. They rely on their supply chains to deliver the parts they require to make cars.

The parts do not arrive before or after they need them. Instead, they arrive the moment they need them.

All the terms above have virtually the same meaning.

All the terms above have virtually the same meaning.

Advantages of just in time

Manufacturers like to use JIT because it is a more cost-effective way of holding stock. It is only effective, however, when you do it properly. The advantages are:

Space: if the turnaround of stock is fast, companies do not need as much storage space. Less space means smaller warehouses to rent or build. This subsequently frees up money for other parts of the business.

Waste: items are less likely to deteriorate or become obsolete if stock turnaround is fast. There is also a reduction of waste. The company saves money because it is spending less on excess stocks.

Investment Size: just in time inventory management is ideal for smaller businesses. It is especially useful for businesses that cannot buy large amounts of stock in one go. Cash flow is also healthier if you can order stock as and when you need it.

Greater Flexibility: as your production runs are extremely short, it is easier for your company to halt production. It can, for example, stop producing one product and rapidly switch to a different one. In other words, it is better able to respond to changes in customer requirements.

Addressing Mistakes: employees are more likely to detect mistakes in production more quickly and fix them.

Taiichi Ohno, a Japanese industrial engineer and businessman, was the father of the Toyota Production System – Toyota’s Just in Time system. It subsequently became known as ‘Lean Manufacturing’ in the US. Next to him in the image above is the old Japanese Toyota logo from 1935 to 1989. (Image: Adapted from Wikipedia)

Taiichi Ohno, a Japanese industrial engineer and businessman, was the father of the Toyota Production System – Toyota’s Just in Time system. It subsequently became known as ‘Lean Manufacturing’ in the US. Next to him in the image above is the old Japanese Toyota logo from 1935 to 1989. (Image: Adapted from Wikipedia)

Disadvantages of just in time

Before deciding whether to adopt a JIT inventory management strategy, you should weigh up the possible disadvantages carefully. When they do occur, they can have a devastating impact on the business. The disadvantages are:

You Lack Stock: if you have virtually no stock, you must have procedures in place to make sure stock can become available rapidly. If the supplies you need for manufacturing do not arrive on time, you are in trouble.

Less Control: if supplies do not arrive on time, you won’t be able to supply your customers punctually. Your company could lose customers. In fact, they may tell others that you are unreliable.

Losing customers and potential future business could be the kiss of death for many companies.

Requires Excellent Planning: you must understand your sales trends and variances. The ability to forecast demand accurately is crucial.

You need to have state-of-the-art forecasting software, models, and suitably qualified staff. Otherwise, you are at serious risk of failing to supply your customers on time.

Strikes & Natural Disasters: a natural disaster or a major strike may interfere with the flow of supplies to your company. In fact, it could bring production to an abrupt halt.

Big Orders: you are less likely to be able to meet an unexpected giant order.

Experts say that just in time inventory management is one of the best ways to manage inventory. However, you must do it properly.

It is not, however, without risks. A good JIT strategy has significant rewards and is ideal for companies that can plan ahead carefully. It also helps you build strong relationships with your suppliers.

The Toyota Production System introduced many concepts to the West, as well as some Japanese terms. For example, Kaikaku means to change a system drastically, while Kaizen is all about implementing many small changes.

Video – What is ‘Just in Time’?

In this Fishbowl video, James Shores explains what ‘Just in Time’ is.