What is machinability? Definition and examples

Machinability is a characteristic of a material, such as a metal, that makes it easy to drill, shape, cut, grind, etc. The term refers to the ease with which we can machine, for example, a metal. In this context, ‘to machine’ means ‘to cut, drill, shape, etc.’

Materials with good machinability can be cut with relatively little power and low cost. It is possible to cut them quickly so that we can obtain a good finish easily. Additionally, they do not wear the tooling much.

The measure of a material’s machinability also takes into account the quality of finish achievable without causing damage to the machining equipment.

Most factors that improve a material’s performance are bad for its machinability. Engineers, therefore, are challenged to find materials with relatively good machinability that do not undermine performance.

Collins Dictionary has the following definition of the term:

“The machinability of a material is how easily it can be machined using a cutting tool.”

Predicting machinability is a challenge

Machining has many variables, which can make it extremely difficult to predict how easily materials can be machined. Engineers focus on two sets of factors:

- The work materials’ condition. This includes grain size, microstructure, chemical composition, hardness, yield strength, tensile strength, and heat treatment.

- The work materials’ physical properties. This includes the modulus of elasticity, thermal expansion, thermal conductivity, and work hardening.

According to Wikipedia:

“Other important factors are operating conditions, cutting tool material and geometry, and the machining process parameters.”

Percentage of a normalized value

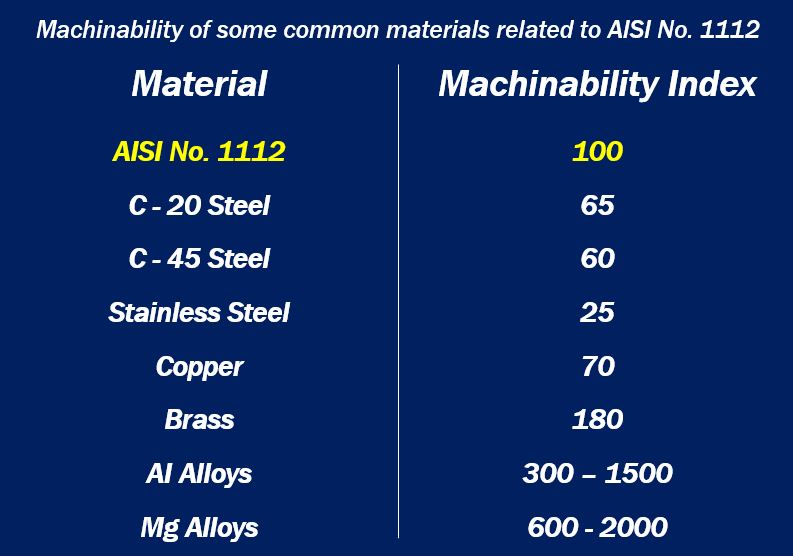

We express machinability as a percentage of a normalized value. The AISI has determined AISI No. 1112 carbon steel a machinability rating of 100%. AISI stands for the American Iron and Steel Institute.

Engineering Toolbox has a list of some common materials and their machinabilities in relation to AISI No. 1112.

No two materials are the same

No two materials that are subject to machining can behave identically when cutting them with the same tool, identical feed rates, the same cutting speed, and using the same machine.

Some materials, such as mild steel, may produce long curly chips. Cast iron, on the other hand, produces short chips.

One material may end with a rough surface while another gets a smooth finish. Others produce lots of heat and rapidly blunt the tool.

Advancements in machining technologies continue to enhance the machinability of harder materials, expanding their applications in industry.

Machinability – example sentences

Below you can see seven sentences containing the word “machinability.” They will show you how to use the term in context:

- “When selecting a metal for the manufacturing process, the machinability of the material is a critical factor to consider for cost-efficiency and quality.”

- “Aluminum is often preferred in high-speed machining operations due to its excellent machinability and ability to maintain a good surface finish.”

- “The tool wear rate is significantly lower when working with materials that have high machinability, which reduces downtime for tool replacement.”

- “Manufacturers often seek to improve the machinability of alloys by adding specific elements that facilitate easier cutting and shaping.”

- “In the aerospace industry, the machinability of titanium alloys is a major consideration due to the complex shapes and precision required for aircraft components.”

- “The machinability index is a valuable guide for machinists to determine the appropriate cutting speed and feed rate for different materials.”

- “Enhancements in machining fluids have been shown to improve the machinability of tough materials by providing better lubrication and cooling during the cutting process.”

Two Videos

These two YouTube videos come from our sister channel, Marketing Business Network or MBN. They explain what the terms “Machinability” and “Machine” mean using easy-to-understand language and examples:

-

What is Machinability?

-

What is a Machine?