Make-to-Order or MTO is a business manufacturing process where customers customize the product they want to buy. The customer places the order first, and then the company manufactures it. In other words, the buyer designs the product with certain specifications. We also call it Build-to-Order or BTO.

Make-to-Order is ideal for companies that want to focus on low volume and highly customized products. It is also ideal for businesses that sell expensive goods. If an item is expensive, it is also costly to hold in storage.

For example, an aircraft maker may have to consider this strategy because airplanes are expensive products.

The aircraft maker can make an airplane according to what the customer requires. It doesn’t even need extra inventory.

Lean-Manufacturing-Japan has the following definition of the term:

“MTO (Make-to-Order) is a manufacturing process in which manufacturing starts only after a customer’s order is received.”

“Forms of MTO vary, for example, an assembly process starts when demand actually occurs or manufacturing starts with development planning.”

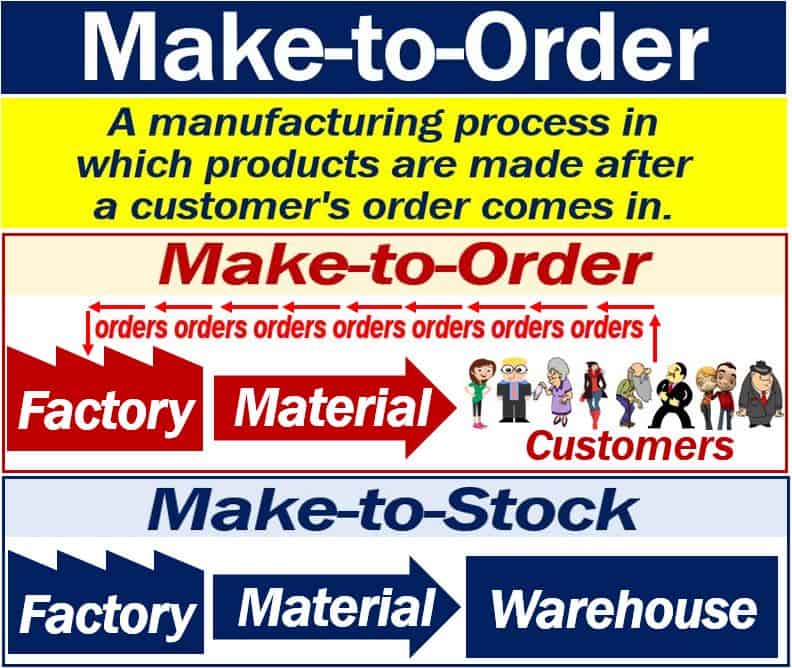

In a make-to-order manufacturing system, the company waits for the customer’s order to arrive before making the finished product. In a make-to-stock system, the company produces the goods beforehand and stores them in a warehouse.

Make-to-order – competitive advantage

By adopting a make-to-order strategy, the company will have a competitive advantage. Being able to give the customer something which is tailor-made is a huge plus in the competitive marketplace.

When a company has a competitive advantage, it means that it has an edge over its rivals. The term ‘marketplace’ means the same as the abstract meaning of ‘market.’

If ‘make-to-order’ products are not in stock, customers have to wait longer for them. They may also have to pay a premium for having something which the supplier has customized.

The MTO strategy starts when customers order something according to their specifications.

The supplier may focus on the internal design or the functioning part of the product. It will then assemble it with the custom-made part of the product when everything is ready.

In many cases, demand determines what manufacturing process the supplier uses. Companies have engineers organizing manufacturing processes as orders come in.

Make-to-order – BMW

One example of a make-to-order company is German luxury car manufacturer BMW. The carmaker allows customers to buy a car that it has already made.

However, they can customize their vehicle according to their requirements.

BMW lets customers design the interior and exterior, the engine, as well as other features.

Customers understand this system is not the same as buying a car that is already in the showroom. They will have to wait several weeks before they receive their vehicle.

In fact, depending on the specs, they may have to wait up to eight months. ‘Specs’ means ‘specifications.’

Just-in-time

Make-to-order is a common process in companies that have a just-in-time strategy. Just-in-time is a manufacturing or inventory strategy in which the company keeps stock levels to an absolute minimum.

Just-in-time contrasts with just-in-case. In a just-in-case system, the company makes sure it has high levels of stocks.