Manufacturing accelerated to 57.3 – a two-year high – in November in the United States, according to the Institute of Supply Management’s (ISM) index.

Analysts say the recent growth in business spending will help push the economy forward during the first quarter of 2014.

According to the ISM, manufacturing activity in the United States expanded in November for the sixth consecutive month; overall the economy has been expanding for 54 consecutive months.

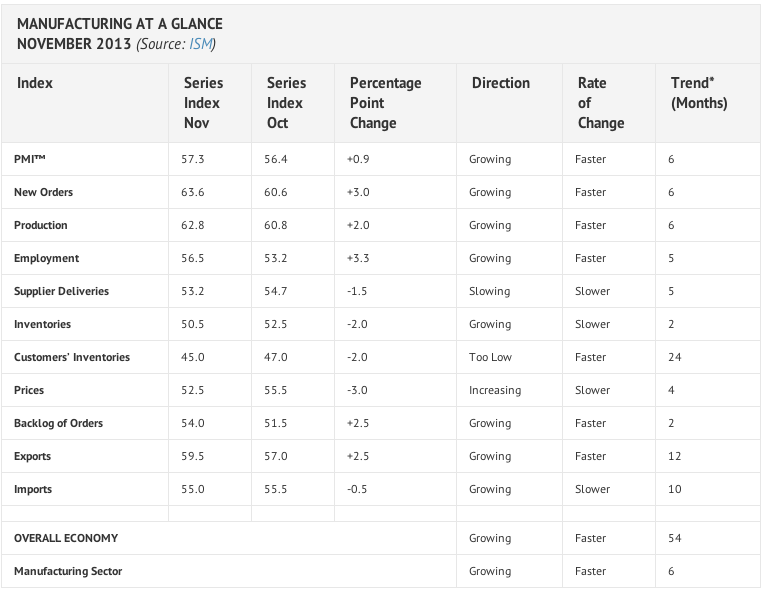

Below are some highlighted data from the November 2013 Manufacturing ISM Report On Business:

- The PMI (Purchasing Managers’ Index) registered 57.3%, a rise of 0.9 percentage points on October’s reading.

- Since June, 2013, the PMI has risen every month.

- New Orders Index registered 63.6% in November, an increase of 3 percentage points compared to October.

- The Production Index registered 62.8%, an increase of 2 percentage points.

- The Employment Index rose 3.3 percentage points, registering at 56.5%. This is the highest reading since April 2012.

Bradley J. Holcomb, CPSM, CPSD, chair of the Institute for Supply Management™ Manufacturing Business Survey Committee, said:

“With 15 of 18 manufacturing industries reporting growth in November relative to October, the positive growth trend characterizing the second half of 2013 is continuing.”

*Number of months moving in current direction.

*Number of months moving in current direction.

Manufacturing accelerated globally

There are signs that manufacturing is picking up worldwide. According to the National Bureau of Statistics in China, factory growth in November was the same as in October, which was better than expected.

In the Eurozone manufacturing, led by Germany, expanded more than was initially estimated, according to Markit Economics.

Indian GDP growth during the 2nd quarter of 2013 surprised experts.