Wetting ability is a liquid’s ability to maintain contact with another surface, to spread easily and uniformly over the surface of another solid or fluid. A liquid with high wetting ability forms a thin, continuous film when it spreads over the surface of something.

A liquid’s wettability – its degree of wetting – is determined by a force balance between cohesive and adhesive forces.

At the point in which the fluid touches the surface of a solid – the liquid-solid surface interface – if the fluid’s molecules have a stronger attraction to the molecules of the solid surface than to each other – the adhesive forces are greater than the cohesive forces – wetting of the surface occurs.

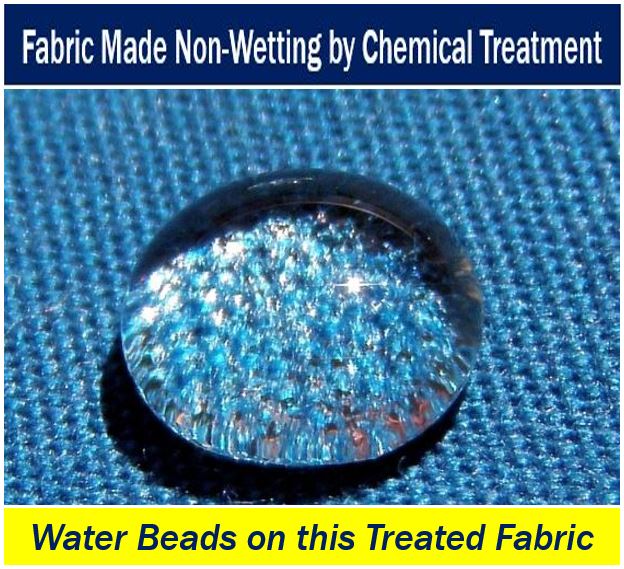

On the other hand, if the fluid molecules are more strongly attracted to each other than the solid surface’s molecules – the cohesive forces are greater than the adhesive forces – the liquid does not spread uniformly across the surface; instead it beads up.

A fluid with a high surface tension, such as mercury, has very little or no wetting ability. Petroleum, solvents, and other liquids with a low surface tension have a high wetting ability.

Water has medium surface tension. Water’s wetting ability increases if you add a wetting agent to it.

A fluid’s wetting ability is of crucial importance in several industries, including printing, painting, dyeing, and cleaning.

Wetting ability – wetting agents

Wetting agents are substances that reduce a liquid’s – for example, water’s – surface tension, and allow it to spread evenly across a surface, thus increasing its wetting ability.

Reducing the surface tension lowers the amount of energy required to spread drops onto a surface, thus weakening the liquid’s cohesive properties and enhancing its adhesive properties.

Dish soap (British: washing up liquid) is a good example of a wetting agent. With all the food oils on the surface of a dish, cohesive forces make it hard for the water to spread and clean the dish.

The dish soap dissolves these unwanted particles, leaving a clean surface exposed. The soap also reduces water’s surface tension, giving it greater wetting ability, i.e. making it spread more evenly across the entire surface.