If you live in the West, have a great product idea, are convinced there is a market for it and want to manufacture that product, nine people out of 10 will advise you to look for a manufacturer in China.

That is not to say that you are unlikely to find manufacturers in the US and Europe. You will, and there are clear advantages in that. For instance, it is easier to communicate with such manufacturers, easier to verify their manufacturing capabilities, and these companies also have good quality and labour standards.

But manufacturing in China has an advantage that all business owners are most keen on: competitive pricing. Other advantages of China manufacturing include the fact that you will also have a larger pool of manufacturers to choose from. And though some Chinese manufacturers have got a rap in past years for the poor quality of their manufacturing, several of them deliver high-quality standards consistently.

So, how do you go about looking for a factory in China that can manufacture your product?

Here are five steps on how to find a manufacturer in China:

1. Search for a manufacturer online and in your industry network:

What do you do when you want to know about almost anything in the world these days? You go to the internet. A search on Google or on B2B platforms such as Alibaba and Made in China – which connect buyers with suppliers and manufacturers – will throw up hundreds of options. You are likely to find a number of them offering to supply you with the product you want manufactured.

Sometimes, however, entrepreneurs want to manufacture a product that is unique, which they have especially designed because they feel there is a market for it, even if it is a niche market.

Potential manufacturers of this product are likely to be smaller companies, which do not necessarily have an online presence. Alternatively, they may also not have the resources to improve their SEO so that Google displays them on its first page. In today’s world of online marketing, good SEO (Search Engine Optimization) is more than important – it is essential.

Neither do such companies have the resources to pay B2B websites to get the “gold” and “verified” ratings – which are paid ratings – that give the company more visibility in the search rankings of these sites.

To identify such manufacturers you may have to do a bit more work.

Besides the internet, you could ask your friends in the industry or tap wider industry networks and trade associations. You could also write to companies who have a similar product and ask them for recommendations for a manufacturer. The worst they could say to you is: “no”.

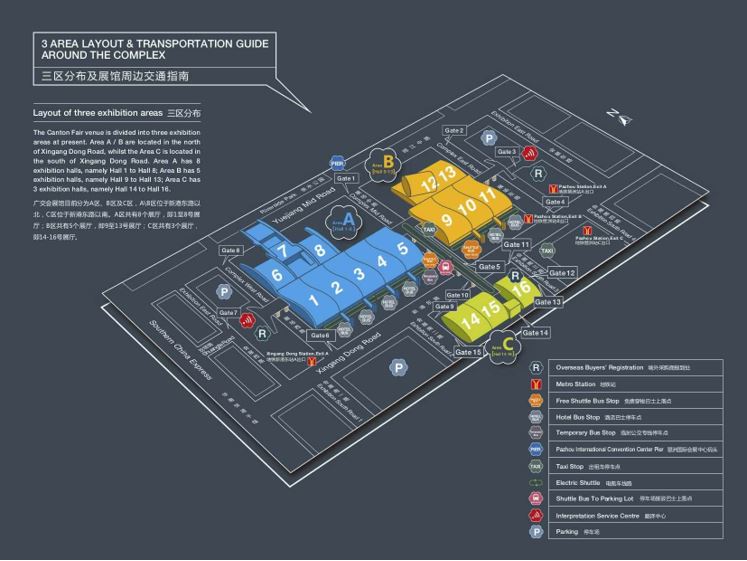

Attending trade fairs in China such as the biannual Canton Fair and Yiwu Fair are also a good way to find more manufacturers.

2. Request for quotation:

2. Request for quotation:

Once you have shortlisted potential manufacturers, you need to send them a request for quotation or RFQ. In this communication, besides stating your manufacturing requirements, you can also ask them a number of questions that will help you assess their manufacturing capabilities and help you eventually choose the one who best meets your requirements for the right price.

Make sure you ask all companies you contact the same questions so that you can compare the various responses you have received.

In this request, you must state your requirements clearly. Among other things, you must:

- Mention the product you want as well as the mode of production required.

- Specify the raw material to be used.

- Ask for the costs per unit for sample/production

- Ask for their minimum order quantity or MOQ and state your required quantities.

- Specify whether you need help with finalising the design

- Ask for time taken to manufacture the product.

- Ask for payment terms.

Other questions you can ask that will aid your selection and verification process can be:

- How long they have been in the business.

- Have they manufactured for western companies before.

- Their factory address.

- Their business licenses and other certifications, including those related to the production line.

3. Ensure they are manufacturers not traders or wholesalers:

Quite often, the suppliers you find online happen to be traders and not manufacturers.

Depending on your manufacturing requirements, and your product’s viability in the market over the years, you will want to find a manufacturer and not a trader as that will lower your price per unit. This is because when you import from China using traders or middlemen, they take a cut that will eat away at your profits.

Depending on your manufacturing requirements, and your product’s viability in the market over the years, you will want to find a manufacturer and not a trader as that will lower your price per unit. This is because when you import from China using traders or middlemen, they take a cut that will eat away at your profits.

This is why once you shortlist potential leads from your internet and industry searches, you need to check if these companies are indeed manufacturers and not simply traders.

How do you do that?

One good way is to look at what their product range is. Manufacturers will be those companies that offer a product from a similar family. For instance, silicone molds and silicone spatulas. A trader will be someone with a wide variety of products on offer. Even if the products they offer are from the same family – say kitchen equipment of different kinds – they are more likely to be traders than someone who offers 25 products made entirely of silicone.

The details the potential manufacturers provide while responding to your request for quotation will help you verify whether the company you are in touch with is indeed legitimate.

You could also ask the companies you shortlist if they are open to a factory audit by a third party (which is recommended anyway before you start production). Factories in China are more likely to be receptive to this suggestion than traders.

4. Request a sample:

Once the suppliers you have contacted respond with their quotations, you can review the quotations and shortlist your favourites. You then ask these shortlisted companies for a sample.

It is important to assess a sample before you sign any long-term agreement with the factory because the sample will be a good indicator of the factory’s manufacturing capability and whether it can meet your quality standards.

But here too you need to be careful. It is not unknown for a factory to send across a so-called “golden sample” which looks awesome, but which has been either sub-contracted to another factory or made with better materials than those that will be used during mass production. While this may be rare, it is known to happen.

You can avoid most of these pitfalls by a thorough verification process, which is an integral part of the process of finding a manufacturer in China anyway.

You can avoid most of these pitfalls by a thorough verification process, which is an integral part of the process of finding a manufacturer in China anyway.

Admittedly, while it is not unusual for samples to be slightly different from the mass-produced product, the factory must ensure that the finished product is as close to the sample as possible.

For this, it may be advisable for you to draw up a detailed agreement with the manufacturer that outline quality standards as well as acceptable and unacceptable deviations.

If you have any modifications or improvements to the sample, make sure that they are reflected in the agreement you draw up with the supplier.

5. Visit the factory

If their sample is great and you have built a good relationship with a potential supplier via email and on the phone, you are probably coming around to thinking that this supplier is “the one”. As a last step, however, you must consider visiting the factory yourself before moving to close the deal by placing your first big mass production order.

This is just to ensure that the manufacturer is legitimate, and is indeed who it claims to be.

A factory visit is a good way to assess manufacturing capability, production expertise, quality control, issues related to workers’ rights and so on. This step is recommended especially if the quality of the product and the rights of workers who manufacture it are especially important to the industry you are in and your reputation as a business (as it should be).

Most legitimate and reliable manufacturers are also open to signing non-disclosure agreements with buyers to protect their intellectual property. Many of them do far too much business with companies in the West to risk it by compromising on the IP rights of their clients.

***

Alternatively, the factory visit as well as the whole process mentioned above – finding a reliable supplier, asking for a quotation, verifying their credentials to ascertain they are manufacturers and not traders, the back-and-forth of getting a sample made, and the factory visit before the signing of a long-term agreement – can also be handled by independent third parties known as sourcing agents.

For a fee, these agents do all this for you and even see off the shipment at the ports in China.

For a fee, these agents do all this for you and even see off the shipment at the ports in China.

Sourcing agents are different from traders. They act as your representatives on the ground and look after your best interests – from understanding what you want from your product, identifying a reliable supplier, studying your designs and suggesting any revisions, ironing out problems in the sample-making process, attending to problems that crop up during the production process as well as ensuring that packaging is adequate and the product is shipped to you within the desired lead time.

Sourcing agents are especially useful for smaller businesses who do not have the time or resources to either visit China or set up an overseas office there. They save you time and money and reduce the probability of costly mistakes cropping up during the production process. They ensure that your sourcing project meets with success.