Metalworking is a complicated industry because of the severe manufacturing procedures. Those who work with sheet metal regularly can easily undertake many processes to get the metal in the output. Sheet metal notching is one of the most important metalworking operations. Notching is a low-cost method that uses a punch press to remove undesirable or superfluous material from the workpiece’s outer borders. There are many instruments available that allow you to do notching at a high rate while making precise cuts and reducing workpiece damage. Roguefab tube notcher provides the essential and premium quality tools for creating fish-mouth notches in metal.

This article goes through the specifics of tube and pipe notcher tools.

Making Use of the Tube Notcher

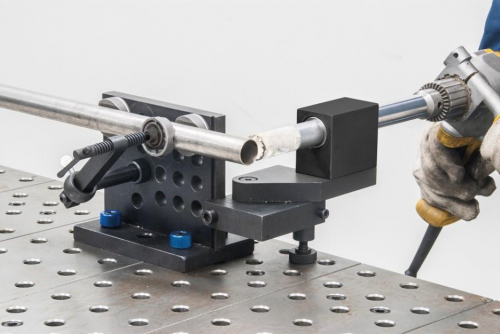

Foremost, if you’re placing the tube notcher on a drill press, ensure sure the unit’s base is square to the main body, the foot is securely secured to the table, and the shaft is centred squarely beneath the chuck. Place the shaft’s tri-flat part in the chuck, making sure that each chuck point is in contact with each shaft flat. Before turning on the drill press, check the up and down action of the drill press spindle and make sure there is no binding or friction in the tube notched. If you’re going to use the tubing notcher on a tabletop or with a hand drill, ensure sure the tool’s base is securely fixed to a stable bench-top and tightly gripped in a large mounted vice.

Determine the angle of the “fish-mouth” notch to be cut into the metal tubing once you’ve set up your tube notcher. Loosen the three lock nuts only slightly, use the gauge to adjust the tubing clamp to the desired angle, and then securely tighten the lock bolts again. Now, using the curved part of the clamping hoop, insert your tubing into the “V” notch and tighten it with the “T” handle. Keep in mind that the “fish-mouth” should always be at the end of the pre-cut segment of tubing, not in the centre. The arbour carrier is attached to the machine’s main body. Based on the angle of the tubing clamp, the arbour carrier allows you to alter the location of the hole saw. Always maintain the saw’s groundbreaking as near to the job as possible to improve cutting accuracy and reduce extra vibration.

Before cutting your tubing, check for sure the locking pin is removed and the saw is properly fastened to the arbour carrier. Set the speed of a drill press between 250 and 500 RPM, and for hand drilling, merely keep the variable speed low. When cutting non-steel tubes in this manner, slower is better to avoid excessive heat accumulation and little vibration. Also, make sure you have enough cutting lubricant on the metal saw teeth and that you feed the saw carefully. Make a few trial cuts on scrap tubing to gain a feel for the tool, and then you’ll be ready to cut your precision “fish-mouth” notches.

Things to Consider When Using a Tube and Pipe Notcher

When putting the tube notcher on a drill press, make sure the unit base is square to the main body, the foot is secured to the table, and the shaft is centred under the chuck. Place the tri-flat section of the shaft in the chuck so that each chuck point contacts each shaft flat. Before you start the drill press, examine the up and down motion of the drill press spindle and make sure there is no friction.

Once the tube notcher is set up, it is critical to calculate the angle of the fish’s mouth notch. Loosen the three-lock bolts slightly and use a gauge to adjust the tubing clamp to the desired angle before tightening the lock. Using the clamping hoop, insert the metal tubing into the V-shape notch and tighten it with the T-handle. It is vital to note that the fish mouth is located towards the end of the tube rather than in the middle. The arbour carrier is positioned to the machine’s main body, allowing you to give accurate change for whole cutter placement based on the tubing clamp angle. Always keep the cutting edges of the saw close to the metal. This improves cutting accuracy and lowers vibration. Before you begin metal notching, remove the locking pin and securely tighten the saw to the arbour carrier.

Precautions and Operation Tips for Tube and Pipe Notchers

When using a pipe notcher, keep the following safety considerations in mind:

- Because a tube notcher employs saw bits with sharp teeth to produce precise cuts, eye protection is required. This will shield your eyes from flying metal chips and debris.

- Wearing loose clothing or jewellery while operating machines might lead to workplace accidents.

- Because the edges of the fishmouth notches are extremely sharp, it is critical to use strong gloves when using the machine to avoid hand injury.

- Make sure to grind the sharp edges down before welding the notched tube to another item.

- Maintain a clean arbour shaft free of metal chips, dust, dirt, and debris.

- To maintain the arbour shaft in place, clean the notcher after each use and replace the lock pin.

- When using a tube notcher, keep the feed speed slow and the saw teeth lubricated with cutting oil.

Final Words

With this knowledge, you should be able to use pipe notcher equipment successfully to make exact cuts. However, there is much more technical knowledge you must be aware of. Using a reputable sheet metal tool manufacturing and supply firm will assist you in this area. Roguefab tube notcher is a market leader with a vast range of sheet metal fabrication tools. They provide high-quality pipe and tube notching tools,hole saw pipe and tube notchers, vent notchers, and other accessories that are effective for cutting and notching materials of varied thicknesses.

Interesting Related Article: “How to Properly Connect Pipes and Fittings“