Titanium is a unique and versatile metal that is well known for its strength, corrosion resistance, and lightness. It has become increasingly popular in various industries such as aerospace, medical, and automotive due to its excellent properties. However, machining titanium can be a challenging task as it requires specialized techniques and precision tools to achieve the desired results. In this blog post, we will discuss the challenges involved in machining titanium and the importance of precision dies and tools.

Challenges in Machining Titanium

Titanium is known for its high strength, low thermal conductivity, and chemical reactivity, making it a challenging material to machine. The cutting process of titanium generates high temperatures that can cause thermal expansion and deformation of the material, resulting in dimensional inaccuracies. The material is also chemically reactive and can react with the cutting tools and other components in the machining environment. Therefore, special care must be taken to ensure that the cutting tools and equipment are resistant to chemical reactions.

Cutting Tools for Machining Titanium

The cutting tools used for machining titanium must be made of high-speed steel or carbide to withstand the high temperatures and forces generated during the process. The cutting tool geometry is also essential to reduce cutting forces and heat generation, resulting in better accuracy and surface finish. The cutting tool should have a large core diameter, a small cutting edge radius, and a high helix angle to reduce cutting forces and improve chip evacuation. Furthermore, the cutting tool should have a positive rake angle to reduce cutting forces and prevent tool wear.

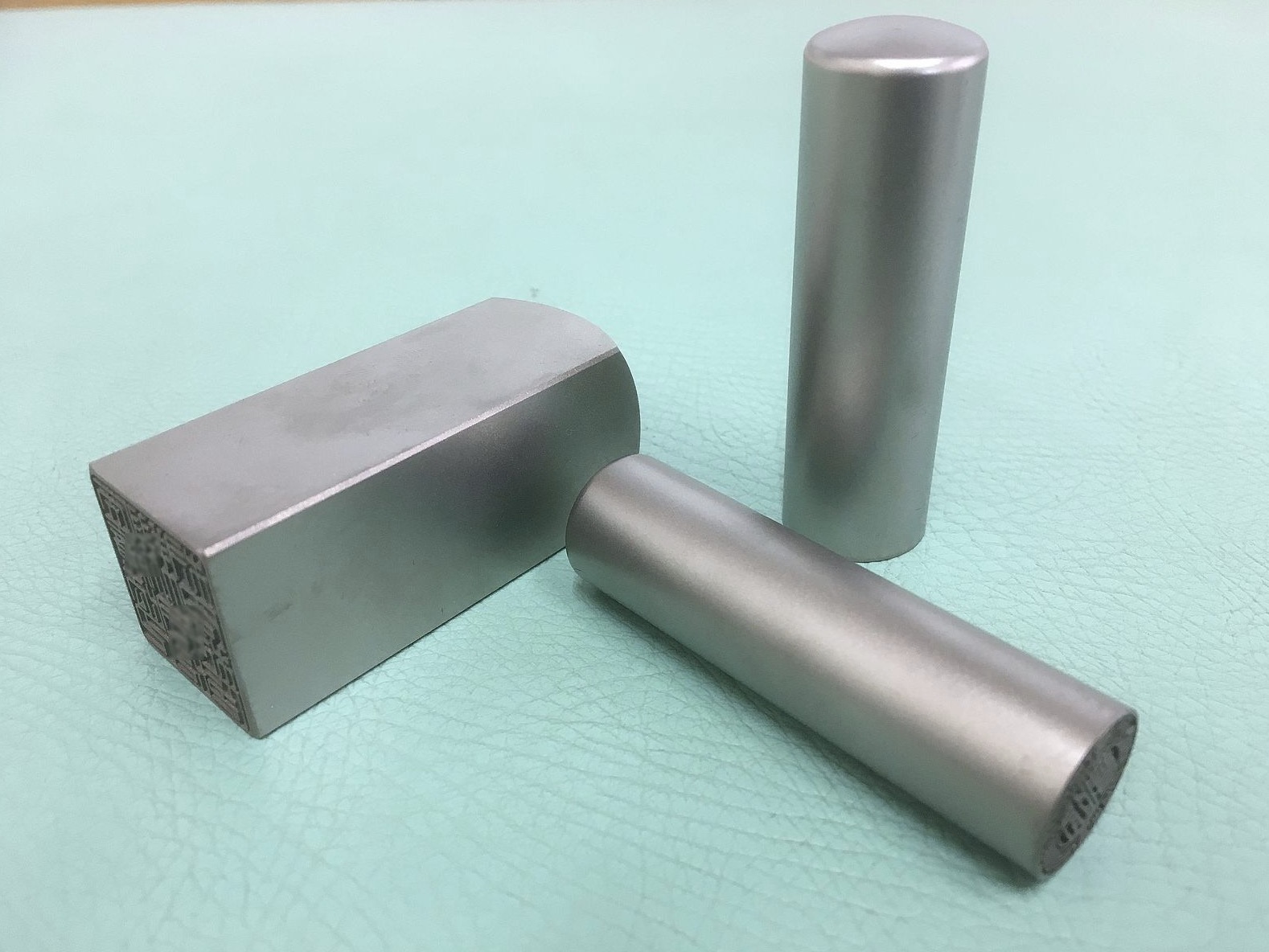

Precision Dies and Tools

Precision dies and tools are essential components of the machining process. They are used to produce high-quality components with tight tolerances and dimensional accuracy. The precision of the dies and tools is critical to achieving the desired results in the machining process. They are made of high-quality materials such as tungsten carbide and are designed to withstand the high forces and temperatures generated during the machining process.

Coolants and Lubricants

Coolants and lubricants play a crucial role in the machining process. They are used to reduce the heat generated during the process, resulting in better accuracy and surface finish. Coolants and lubricants also help in chip evacuation and prevent tool wear. The most common types of coolants used in machining titanium are water-soluble oils, emulsions, and synthetic coolants. Lubricants are also used to reduce friction between the cutting tool and the workpiece, resulting in better surface finish and longer tool life.

Conclusion

Machining titanium is a challenging task that requires specialized techniques and precision tools. The cutting tools used in machining titanium must be made of high-quality materials and designed to reduce cutting forces and heat generation. Precision dies and tools are also essential components of the machining process, and their quality and accuracy are critical to achieving the desired results. Coolants and lubricants are used to reduce heat generation, prevent tool wear, and improve surface finish. By employing these techniques and using high-quality tools and equipment, manufacturers can produce high-quality components from titanium.