Researchers at the U.S. Department of Energy’s National Renewable Energy Laboratory (NREL) have developed a recycling method that they believe “could incentivize both improved plastics reclamation and acceleration of the bioeconomy.”

The recycling method involves transforming objects made from polyester material polyethylene terephthalate (PET) into more valuable products with a longer lifespan.

Their research was published in the journal Joule (citation below).

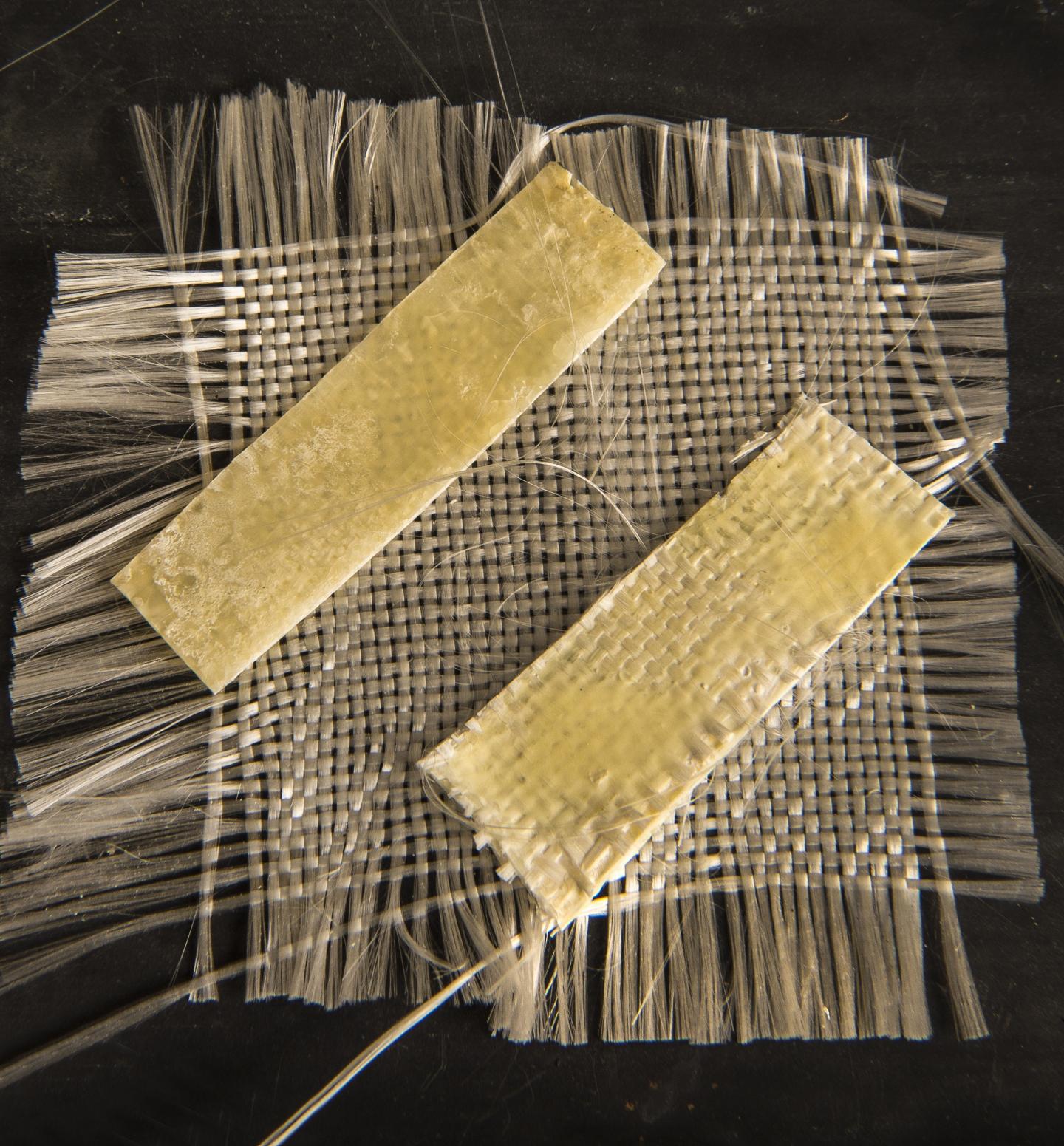

The team converted reclaimed PET (rPET) bottles into fiberglass-reinforced plastics (FRPs). They achieved this by combining rPET with bio-based compounds to produce two types of high-value FRPs.

A supply-chain analysis revealed that this strategy for plastics upcycling offers substantial energy savings and greenhouse gas emission reductions compared to the process for producing standard petroleum-based FRPs.

According to the study’s summary,

“By harnessing the embodied energy in reclaimed PET (rPET) and implementing renewably sourceable monomers with distinct chemical functionality relative to petroleum building blocks, the resultant rPET-FRPs exhibit considerably improved material properties and are predicted to save 57% in the total supply chain energy and reduce greenhouse gas emissions by 40% over standard petroleum-based FRPs.”

The team believes that the technology will help incentivize the economics of plastics reclamation.

“Most recycling today is downcycling—there’s very little financial motivation,” said NREL Senior Research Fellow Gregg Beckham, one of the primary authors of the paper.

“Knowing that 26 million tons of PET are produced each year but only 30% of PET bottles are recycled in the United States, our findings represent a significant advancement in enabling the circular materials economy.”

“The scale of PET production dwarfs that of composites manufacturing, so we need many more upcycling solutions to truly make a global impact on plastics reclamation through technologies like the one proposed in the current study,” said first author Nicholas Rorrer, an engineer at NREL.

Citation

Nicholas A. Rorrer, Scott Nicholson, Alberta Carpenter, Mary J. Biddy, Nicholas J. Grundl, Gregg T. Beckham, “Combining Reclaimed PET with Bio-based Monomers Enables Plastics Upcycling”, Joule, 2019, https://doi.org/10.1016/j.joule.2019.01.018.