A ball valve is a type of valve that regulates the flow of liquid by using a rotary ball with a bore. The ball is attached to a handle that turns 90 degrees (quarter turn) either to allow the fluid to pass through or completely block it.

They are however limited when used to regulate flow as they are less accurate than other control valves. Regardless, they still ensure quality sealing services even where contaminated fluids are involved.

To help you choose the right ball valve for your industry, here are a few steps to guide you.

1. Pick the Appropriate Valve Size

This is one of the most important steps when picking the right ball valves for your needs. A bigger size will ensure maximum flow of fluid but in turn, will cause a massive drop in fluid pressure. This can be detrimental to the general operations of the structure.

An undersized valve will ensure maximum pressure of the fluid but in turn will restrict the flow. This may cause maintenance issues due to excessive pressure build-up and blockages.

2. Choose the Right Material

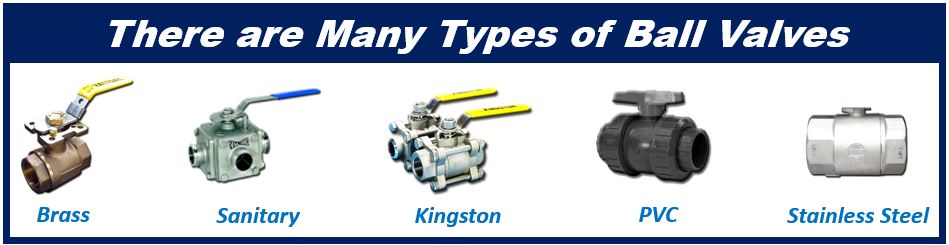

Depending on the industry, ball valves come in different materials such as stainless steel, PVC, brass, and ceramic, among others.

When operating in high temperatures, the material used to construct the valve matters a lot. To reduce the cost of maintenance or replacement, it is advisable that you choose a valve with materials able to withstand high temperatures and fluctuations.

Corrosive fluids also affect the integrity of the valves they flow through. When dealing with corrosive fluids such as wastewater, you should choose a valve with corrosion-resistant properties.

3. Performance Expectations

Different ball valve designs work for different industries. Your selection should be based on the type of operation intended. For example, chemical plants have customized ball valves for their operations. This is due to extreme working conditions such as very high temperatures or extremely corrosive fluids.

4. Maintenance

Generally, ball valves are low maintenance parts of the piping system. The environment in which the valve operates however dictates the rate and cost of maintenance involved. In extreme environments, maintenance is generally more frequent than in normal working environments.

The quality of the valve also determines the maintenance schedule. The better quality valves usually cost less to maintain and generally last longer. Picking the right material, therefore, helps to bring the cost down.

5. Certifications

Safety measures are paramount across all industries the world over. Poor quality valves are a safety hazard in the environments they are used with leaks and breakages being a common occurrence. As such, it is important that you ensure your ball valves have all the necessary certifications and have been tested especially for leaks in air and hydro tests.

6. Expected Working Temperatures and Pressure

Due to the varying viscosity with fluids, their flow rate also differs. This rate of flow dictates the fluid pressure within the pipes. Ball valves are differently designed to work with different pressures. Be sure to take these into consideration when choosing a ball valve.

Winding Up

There are many important aspects to consider when choosing the right ball valve for your industry. Many more aspects will come to light as you go about picking other parts of the piping system. These are however the steps that will guide you the right way.

Make sure you choose a reputable ball valve manufacturer for your operations. In the end, quality is always the better choice.

Interesting related article: “What is Maintenance?“