For woodworking manufacturers who want to meet large orders of bulk clients, two factors are critically important: reaching the desired precision while maintaining the necessary volume. If manufacturers manage to get both these things right, it will not only impact manufacturing efficiency but also enhance their customer experience, which will always translate into higher profits. CNC panel saw emerges as the single most effective machine that can help you meet both these needs without even compromising a tiny bit of quality. How does a CNC panel saw equip manufacturers to uphold quality while scaling production? Let’s see.

What is CNC?

CNC stands for Computer Numerical Control. This technology automates tools using computers that execute pre-programmed sequences of commands to control machines. As a fundamental component of modern manufacturing, CNC allows for high-precision machining of various materials, including wood, metals, and plastics.

In particular, a CNC panel saw is a computer-controlled saw that is extensively used in the woodworking and manufacturing industries for cutting panels. It is a highly accurate and efficient way of cutting in a mass-production environment where consistency and quality become non-negotiable.

Why CNC Panel Saw Ensures Production Accuracy?

A CNC panel saw is a pivotal piece of equipment that lies at the heart of precision and efficiency in woodworking industries.

CNC-Controlled

CNC panel saws are equipped with advanced computer-controlled systems that execute precise cutting operations with minimal margin for error. These systems interpret digital designs or patterns with utmost accuracy, translating them into precise cutting motions. As a result, each cut is consistent, ensuring uniformity across all pieces in a production run.

CAD & CAM Equipped

CNC panel saws are capable of executing intricate cutting patterns and complex shapes with precision because the automatic panel saw machine can be seamlessly integrated with Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software. This integration allows manufacturers to design intricate patterns digitally and directly translate them into cutting instructions for the CNC panel saw. Whether it’s intricate patterns, beveled edges, or precise angles, CNC panel saws can achieve the desired results with accuracy and consistency.

How CNC Panel Saw Expand Production Capacity?

Beyond ensuring accuracy, CNC panel saws are instrumental in expanding production capacity within woodworking industries. Here’s how

Automated Cutting Process

CNC panel saws significantly increase throughput by automating cutting processes. These machines can cut multiple pieces simultaneously and operate continuously, minimizing downtime between cuts. As a result, manufacturers can produce larger volumes of components in a shorter amount of time, effectively expanding their production capacity to meet growing demands.

Optimization of Material Utilization

CNC beam saw machines optimize material utilization through advanced nesting algorithms and cutting strategies. By maximizing the number of components that can be cut from a single sheet of material, these machines reduce material waste and increase yield. This efficiency not only lowers production costs but also enables manufacturers to make the most out of their raw material inventory, effectively expanding their manufacturing capacity without increasing material costs.

Flexibility in Production

CNC panel saws offer flexibility in production by accommodating a wide range of cutting requirements. Whether cutting plywood, MDF, particleboard, or other materials, these machines can adapt to various production needs with ease. Moreover, they can execute intricate cuts, beveled edges, and complex shapes, allowing manufacturers to diversify their product designs and cater to different market segments. This versatility enhances the overall agility of production processes, enabling manufacturers to respond quickly to changing customer demands and market trends.

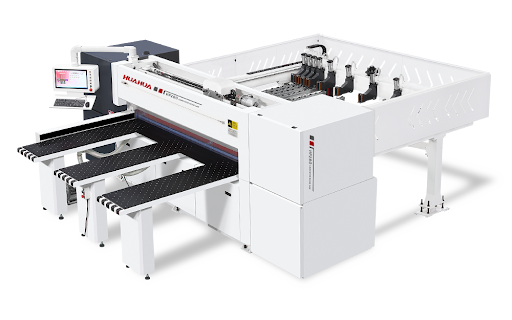

Introduce Huahua’s CNC Panel Saw: HP280

To meet the demand for enhancing accuracy and production capacity, our revolutionary CNC panel saw, Huahua’s HP280, is designed to tackle these challenges.

-

Pneumatic Clamping

This CNC automated panel saw machine comes with a unique two-finger clamping system that securely holds panels in place during the cutting process. This is the best way to enhance the precision of cuts while also protecting the panel surfaces from damage.

-

Intuitive PC Control System

This CNC panel saw is easy to use as it is equipped with an industrial PC control system, which makes its interface highly intuitive with all the operational hints and a troubleshooting guide. The compatibility of this machine with barcode management or factory automation software further integrates it into modern production environments in order to improve working efficiency in your CNC machining factory.

-

Productive Saw Carriage

The saw carriage in Huahua’s HP280 promises both heightened production capacity and uncompromising quality in woodworking operations. With independently lifted and lowered main and scoring saws, this innovative system allows for precise adjustments tailored to varying cutting thicknesses and widths, ensuring optimal accuracy across diverse materials. And equipped with an 18.5kW main saw motor, swift saw blade replacement capabilities, and a rapid 4000rpm main saw shaft rotation, the HP280 delivers unparalleled capacity. Furthermore, the incorporation of a precision reducer enables automatic adjustment of cutting height based on panel thickness, ensuring consistent depth and flawless cuts with every pass.

Conclusion

By using Huahua’s HP280 CNC panel saw, woodworking becomes easy and can meet large production needs without seeing any dip in quality. Huahua is one of the leaders in providing the high-quality CNC panel saw. Through decades of experience and a steadfast commitment to innovation and quality, Huahua can be your reliable partner in the panel-cutting machine industry. Visit their official website and contact them to grasp bigger business opportunities!

Interesting Related Article: “How to Choose the Right CNC Machining Service Provider: A Complete Checklist“