With the various development trends and advancement in international markets, the titanium industry is set to grow exponentially to a CAGR of a million dollars by the end of 2025.

With titanium boasts some of the most impressive characteristics like low thermal conductivity, lightweight, and high tensile strength, titanium is one of the most common metals used in aeronautical engineering, construction, or medicine.

These factors contribute to its usage in the industry, as various alloys are derived from titanium products. There are different companies like Alloy Metals, one of several leading suppliers and distributors for titanium, that specialize in different titanium products to cater to the standard client.

For instance, titanium can be molded into titanium plates, sheets, or bars. The use of titanium in the market has seen it is classified into three distinct categories:

-

Alpha Titanium alloy

These alloys contain stabilizing components such as nitrogen, aluminum, and oxygen, among others. The presence of oxygen seeks to increase the alloy’s strength to maintain durability and adaptability to high or low temperatures.

-

Beta Titanium alloy

These alloys contain cobalt, manganese, and copper, among others. These components lower defamation significantly, improving the fabric o the metal and increasing durability.

-

Other

Most alloys that fall into this category comprise a mixture of alpha and beta alloys to increase the metal mechanically’s strength significantly. The mix of components seeks to enhance capabilities such as workability and power, generally advancing the fusion.

As alloys compare with pure-grade titanium, combining it with other metals leads to the client’s maximum benefit. Therefore, researching to find out whether titanium’s purpose Is clear before considering alloy use is crucial.

Why Titanium?

Unlike steel, titanium can be used in various industries like airplanes, submarines, and many others. The high tenacious ability in titanium puts its usage as one of the most adaptable and versatile products, especially in exploring space.

Titanium products are also not easily destroyed and can withstand harsh condition like seawater and airspace as it dispels harmful electromagnetic waves acting in the environment. Titanium’s highest strength, as opposed to density, is exceptionally remarkable, making it one of the most durable metals in the environment.

Titanium products are also aesthetically pleasing, giving off a smooth finish to the end product. With low toxicity and a biocompatible front, titanium weighs less.

Titanium plates

Titanium plates are structured according to purpose, structured in different varying thicknesses. For instance, in industrial usage, various purposes are considered before molding a titanium plate into a complete structure. The depth hence comes about when finding the usage of the product and the end product.

Titanium plates can be used for engineering, its tenacity to resist folding, and the quality of materials used before molding the plates in considerable sizes. The plates are also developed in distinct shapes and sizes, which do not allow bending or shaping. Instead, the plates can be modified by cutting them into thin pieces depending on the purpose intended.

Titanium plates are suitable for medical purposes as they do not absorb rays, making them safe and efficient.

Titanium sheets

Titanium sheets can be modified into various shapes due to their ability to bend and manipulate multiple uses. For instance, they can be managed to cover almost any radius and act in sync with the environmental climate changes. The tensile strength and durability propel titanium sheets to adaptability.

The most common of titanium sheets are:

- Grade 2

This titanium sheet is used for commercial purposes in-plant processing and infrastructure development to its cold, formidable nature.

- Grade 5

This sheet is used in cases where forming is not required. Its high tensile strength allows for assurance, especially in high octane activities such as race car driving. The heat emerging from the titanium sheet does not transfer the effect to the metal, making it non-corrosive.

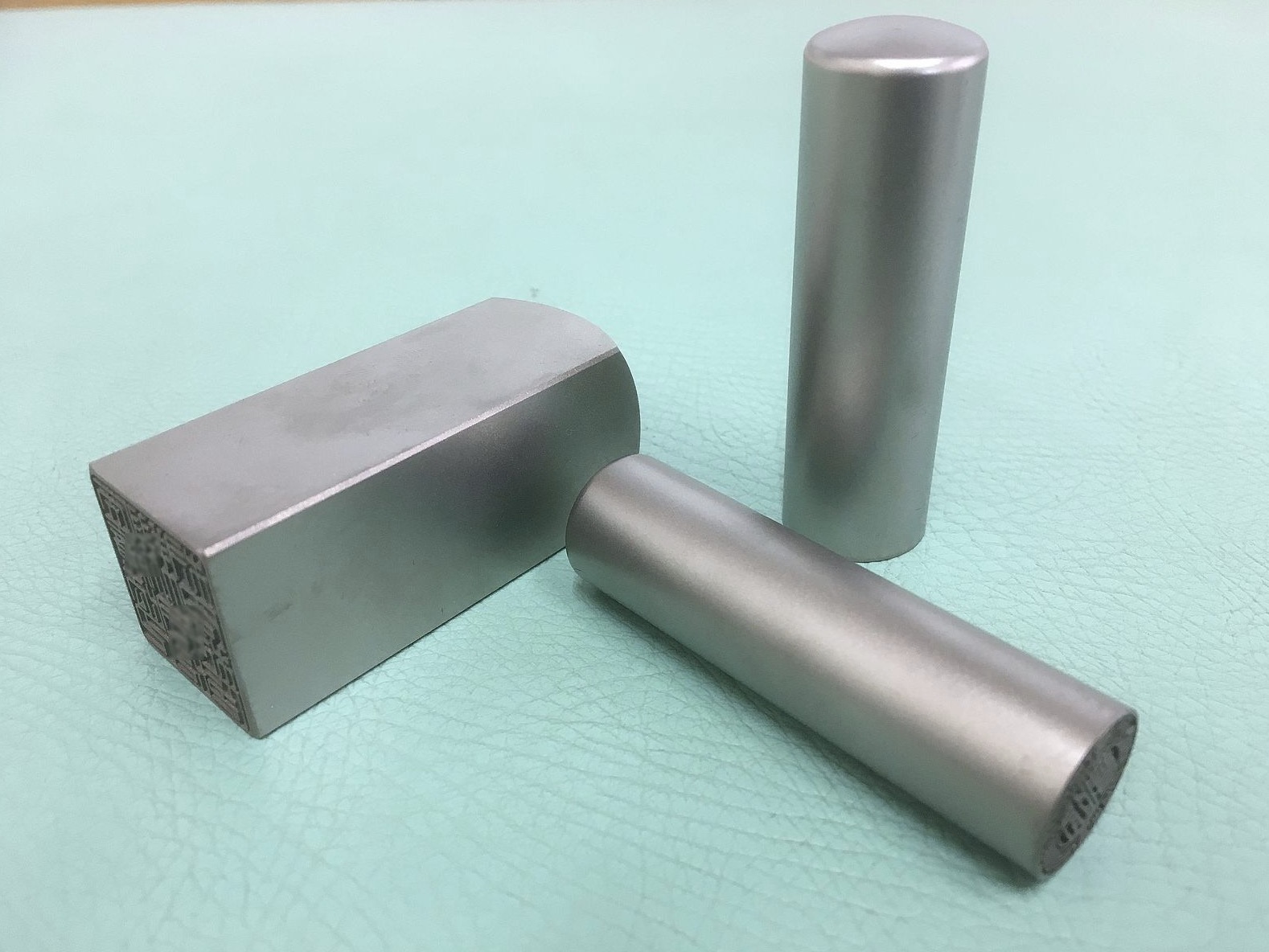

Titanium Bars

As the name suggests, titanium bars are structured to long, dense structures for medical, chemical or structural use. Titanium bars are made by hot rolling titanium alloys to create a solid metal. After this, the bars are polished, welded, and cast into sections, helping to mold the metal. Alloy Metals seek to mold potential titanium bars conveniently for the intended purpose.

Titanium bars are made as they do not contain an unbalanced ratio of titanium versus other materials. These can be manipulated into a round shape with the perfect mold.

Market survey

With the recent survey in market structure as far as titanium products are concerned, it is fundamental to discover the prevalence of titanium products.

Research indicates the probability of titanium products to increase in demand over the coming years. Its excellent characteristics allow for it to be preferred in engineering and medical purposes. The titanium cost is also set to be cheaper than other metals while offering the same qualities as other expensive metals with the same specifications.

The development in processing techniques to allow for innovative methods such as 3D printing will change the science and technology industry by simplifying manufacture. 3D technology also offers a platform for sustainable and preventive measures to avoid waste of raw materials.

With the recent dive in the economic front, titanium is slowly becoming a core ingredient in metal manipulation.

Recent trends in the titanium industry showcase new and upcoming market trends in titanium products to incorporate products that undergo fewer development processes, which significantly improve manufacturing costs.

These trends are expected to revolutionize the industry by providing ingenious solutions to several industries. For instance, the advent of titanium orthopedic implants is set to change the medical field by providing an avenue for better life quality and minimal complications during surgery and minimizing infection risk.

As stated above, with the benefits of titanium products, suppliers, distributors, and developers should ensure they are careful in structuring these products to ensure quality, sustainability, and growth of the titanium industry.

Interesting Related Articles: “Use of Robotics in Manufacturing and Packaging has Changed the Industry Forever“