In commercial and residential spaces, two important factors when choosing a floor are environmental responsibility and durability. Stone Plastic Composite (SPC) flooring is rapidly gaining popularity due to its high resistance to wear and minimal upkeep needs. These qualities not only lower long-term costs but also reduce energy consumption. When compared to traditional wood flooring, SPC proves to be the superior option for a variety of settings. Here’s an in-depth look at why SPC flooring is a better choice.

What is SPC Flooring?

SPC (Stone Plastic Composite) flooring is a rigid-core luxury vinyl product designed for durability and dimensional stability. It consists of multiple layers, including a wear layer, a printed vinyl layer, a rigid SPC core, and an underlayment.

The core is made from a composite of limestone powder and thermoplastics, which sets SPC apart from traditional vinyl or wood-plastic composite (WPC) flooring. This composition makes SPC floors highly resistant to impacts, scratches, and temperature fluctuations, ensuring they remain impervious to water—a significant advantage in areas prone to moisture like kitchens, bathrooms, basements, or commercial environments.

Additionally, the dense core provides effective sound insulation, a key consideration in multi-story buildings or busy commercial areas. SPC’s stability under temperature shifts also means it doesn’t expand or contract like wood, so there’s no need for acclimation prior to installation. Its UV resistance helps maintain surface design, making SPC flooring ideal for high-traffic environments that receive sunlight, like retail stores or offices.

How SPC Flooring Outperforms Wood Flooring

Durability and Resistance to Wear

SPC flooring stands out for its durability. Unlike wood, which is prone to dents and scratches from heavy foot traffic, SPC’s rigid core resists such damage. The top wear layer, often coated with UV protectants, shields the surface from scratches and stains. While wood floors may warp or expand with temperature and humidity changes, SPC remains stable and doesn’t need repairs or refinishing as often.

Real-world examples demonstrate that SPC flooring can last 10 to 20 years or more in high-traffic areas with little maintenance, whereas wood may need refinishing or repair every 5 to 10 years in similar environments. This difference in longevity makes SPC a more attractive option for spaces that endure heavy use, such as offices, hotels, or busy households.

Water Resistance

Water is one of the most common enemies of wood flooring. Wood absorbs moisture, leading to warping, swelling, or even rotting over time. SPC flooring, on the other hand, is completely waterproof due to its unique core composition. This makes it ideal for areas that experience high moisture levels, such as bathrooms, kitchens, basements, and even commercial spaces in humid climates. Unlike wood, SPC does not require any special treatment or coating to protect it from water damage.

Easier Installation and Maintenance

One of the key benefits of SPC flooring is how easy it is to install. Many SPC floors come with a click-lock system, allowing for a floating installation that doesn’t require nails or adhesives. This feature significantly reduces installation time and labor costs when compared to wood flooring, which often requires more complex methods like nailing, gluing, or stapling.

After installation, SPC floors are also low maintenance. They resist staining and only need basic cleaning with a mop or vacuum, unlike wood floors, which require polishing, refinishing, and careful cleaning to prevent water damage. In commercial environments, where time and labor for upkeep are limited, SPC’s resilience to wear and tear ensures minimal disruption for repairs or refinishing.

Cost-Effectiveness and Long-Term Value

In terms of both upfront and long-term costs, SPC flooring offers better value than wood. High-end wood flooring can be expensive, whereas premium SPC options provide similar aesthetic appeal at a lower price point.

Moreover, the low maintenance needs of SPC floors mean fewer future expenditures. While wood floors often need refinishing, especially in high-traffic areas, SPC remains durable with minimal upkeep. For businesses or homeowners looking for a cost-effective solution that combines beauty and practicality, SPC offers a strong return on investment with fewer ongoing costs.

Design Flexibility

Modern printing technologies enable SPC floors to mimic the appearance of wood, stone, or even ceramic, giving them a versatility that rivals traditional materials. While wood offers a natural aesthetic, SPC flooring can provide the same look with higher durability and less maintenance.

SPC floors are available in a wide range of colors, textures, and finishes, offering more design flexibility than many wood options. Importantly, SPC maintains its appearance over time, while wood may lose its luster without regular care. This makes SPC an ideal choice for homeowners or designers aiming for specific styles—whether rustic or contemporary—without the downsides of real wood.

Challenges with SPC Flooring

While SPC flooring offers many advantages, it is important to acknowledge potential challenges. One limitation is that SPC can sometimes feel less warm underfoot compared to natural wood. Although some higher-end SPC options include underlayment that improves comfort, it may not entirely match the tactile warmth of hardwood. Additionally, while SPC is highly resistant to wear, extreme impacts can still cause damage, and repairs may require replacing entire planks.

For those focused on sustainability, the production of SPC flooring involves the use of plastics, which may be a concern for environmentally conscious consumers. However, many manufacturers are working toward more eco-friendly production methods and recycling programs.

Boyu’s SPC Production Line: A Smart Business Solution

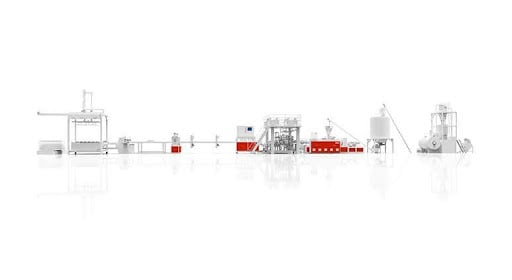

Boyu, an experienced flooring manufacturer, offers advanced SPC flooring production equipment tailored to meet various customer needs. Their production line includes both parallel and conical twin-screw extruders, all built with high-quality CE-certified machines.

Their new SPC180 model is notable for its efficiency and reliability, offering a production capacity of 70-100 tons per 24 hours—three times larger than the SPC110 model. This new model also reduces energy consumption, requires less plant space, and minimizes labor costs.

In addition, Boyu’s patented Synchronized Floral Pattern Technology (EIR) allows manufacturers to produce SPC flooring that closely resembles natural wood, enhancing the aesthetic appeal of their products.

Conclusion

SPC flooring is an increasingly popular choice in both commercial and residential environments due to its superior durability, water resistance, and ease of installation. With advanced production technologies, such as those offered by Boyu, manufacturers can produce high-quality SPC flooring efficiently and sustainably. For anyone looking to balance aesthetics, functionality, and long-term value, SPC is a smart choice.