Traditional lightbulbs will win a reprieve, say MIT and Purdue scientists, who have managed to combine the warm familiar glow of the incandescent lightbulbs, that the EU and several nations want banned, with twenty-first century energy efficiency.

Incandescent lighting has remained virtually unchanged across the world since its birth about 135 years ago. Lighting inside our homes, offices and other buildings is changing rapidly, as regulations aimed at improving energy efficiency are gradually phasing out the old bulbs in favour of the more efficient CFLs (compact fluorescent lamps) and the even newer LEDs (light-emitting diode) bulbs.

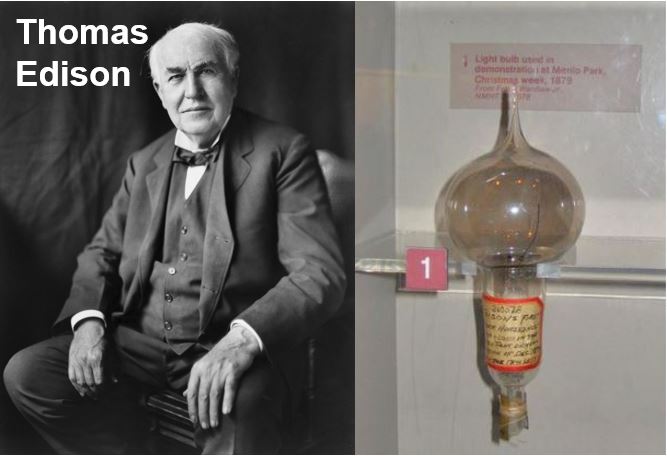

Incandescent bulbs were first commercially developed by Thomas Edison (1847-1931) in 1879 (and still used by cartoonists and illustrators as the symbol of inventive light). They work by heating a thin tungsten wire to about 2,700 °C.

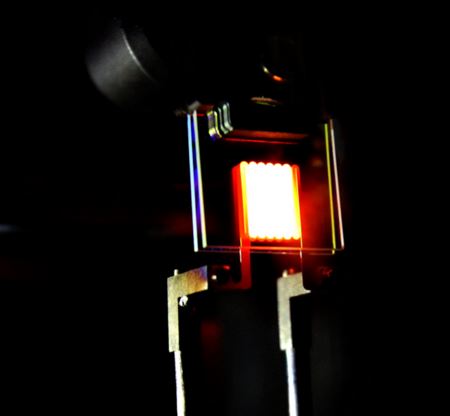

Incandescent lightbulbs to make a comeback. This is an image of a proof-of-concept device made by MIT scientists. It demonstrates the principle of a 2-stage process to make incandescent bulbs more efficient. (Image: mit.edu)

Incandescent lightbulbs to make a comeback. This is an image of a proof-of-concept device made by MIT scientists. It demonstrates the principle of a 2-stage process to make incandescent bulbs more efficient. (Image: mit.edu)

The super-hot wire emits black body radiation, a very broad light spectrum that provides that warm look we all miss when switching from incandescent bulbs to modern ones.

Incandescent bulbs, however, have always suffered from one serious problem: over 95% of the energy that goes into them is lost, mostly in the form of heat. That is why an ever-increasing number of countries are either banning or phasing out the inefficient technology.

Now, however, scientists at the Massachusetts Institute of Technology (MIT) and Purdue University claim they have found a way to change all that.

The researchers published their findings in the academic journal Nature Nanotechnology.

Light recycling

According to the scientists, the key is to create a 2-stage process.

Stage 1: you start with a conventional heater metal filament – yes, the energy-inefficient one. But rather than letting the waste heat dissipate in the form of infrared radiation, it is captured and reflected back to the filament by structures surrounding the filament.

The radiation is re-absorbed by the filament and re-emitted as visible light. The structures – a form of photonic crystal – are made of Earth-abundant elements and can be manufactured using conventional material-deposition technology.

Thomas Edison’s first successful light bulb model. It was used in public demonstration at Menlo Park, California, in December 1879. For 135 years incandescent lighbulbs have not changed that much – until now.

Thomas Edison’s first successful light bulb model. It was used in public demonstration at Menlo Park, California, in December 1879. For 135 years incandescent lighbulbs have not changed that much – until now.

Step 2: this improves how efficiently the system converts electricity into light. Luminous efficiency, a quantity that characterizes a lighting source, takes into account the response of the human eye.

The luminous efficiency of different types of lights are as follows:

– Incandescents – 2% to 3%.

– Fluorescents (inc. CFLs) – 7% to 15%.

– Most compact LEDs – 5% and 15%.

– New two-stage incandescents: up to 40%.

The first proof-of-concept (experimental) units made by the scientists have not yet reached 40%, but only 6.6% so far. However, this starting point regarding efficiency already matches those of some CFLs and LEDs available today, the authors point out.

The two-stage incandescents are already three times more efficient than conventional incandescents.

Incandescent lightbulbs (right) may be making a comeback.

Incandescent lightbulbs (right) may be making a comeback.

The researchers refer to their approach as light recycling, as their material takes the unwanted and useless wavelengths of energy and turns them into visible light wavelengths that are wanted and useful.

Marin Soljačić, Professor of Physics at MIT’s Department of Physics, said “It recycles the energy that would otherwise be wasted.”

Two-stage incandescents rival new bulbs on the market

The authors say the key to their success comes from the design of the photonic crystal, which works for a very wide range of angles and wavelengths. The crystal itself is made of a stack of thin layers, placed on top of a substrate (an underlying substance or layer).

MIT research scientist, postdoc Ognjen Ilic, said:

“When you put together layers, with the right thicknesses and sequence, you can get very efficient tuning of how the material interacts with light. In their system, the desired visible wavelengths pass right through the material and on out of the bulb, but the infrared wavelengths get reflected as if from a mirror.”

“They then travel back to the filament, adding more heat that then gets converted to more light. Since only the visible ever gets out, the heat just keeps bouncing back in toward the filament until it finally ends up as visible light.”

Alejandro Rodriguez, assistant professor of electrical engineering at Princeton University, who was not involved in this work said:

“The results are quite impressive, demonstrating luminosity and power efficiencies that rival those of conventional sources including fluorescent and LED bulbs. [The findings] provide further evidence that application of novel photonic designs to old problems can lead to potentially new devices.”

“I believe that this work will reinvigorate and set the stage for further studies of incandescence emitters, paving the way for the future design of commercially scalable structures.”

Tech has potential for other applications

Prof. Soljačić said the technology they created has potential for several other applications, apart from light bulbs. The same approach could be used for energy-conversion schemes such as thermo-photovoltaics, with ‘dramatic implications’ for performance.

In a thermo-photovoltaic device, heat from an outside source (solar, chemical, etc.) makes a material glow, which causes it to emit light that is turned into electricity by a photovoltaic absorber.

Prof. Soljačić said:

“LEDs are great things, and people should be buying them. But understanding these basic properties – about the way light, heat, and matter interact and how the light’s energy can be more efficiently harnessed – is very important to a wide variety of things.”

“The ability to control thermal emissions is very important. That’s the real contribution of this work.”

Prof. Soljačić added that as far as other practical applications this basic new technology could be used for, “It is too early to say.”

The research was supported by the S3TEC Energy Frontier Research Center funded by the U.S. Department of Energy, and the Army Research Office through the MIT Institute for Soldier Nanotechnologies.

In an Abstract in the journal, the authors wrote:

“We experimentally demonstrate a proof-of-principle incandescent emitter with efficiency approaching that of commercial fluorescent or light-emitting diode bulbs, but with exceptional reproduction of colours and scalable power. The ability to tailor the emission spectrum of high-temperature sources may find applications in thermophotovoltaic energy conversion and lighting.”

Citation: “Tailoring high-temperature radiation and the resurrection of the incandescent source,” Ognjen Ilic, Peter Bermel, Gang Chen, John D. Joannopoulos, Ivan Celanovic & Marin Soljačić. Nature Nanotechnology. 11 January 2015. DOI: 10.1038/nnano.2015.309.

Video – Comparing incadescents Bulbs with CFLs and LEDs

In this video (made two years ago, before this latest study), you can see the three different types of lighting compared.

Comments are closed.