Recent developments in sustainable aviation fuel (SAF) production have seen a breakthrough in utilizing plant waste, particularly lignin, as a feedstock.

Researchers from Washington State University (WSU) have successfully demonstrated a continuous process that could convert lignin, an essential component of plant cells, into a viable jet fuel. This new method promises to enhance the sustainability and performance of aviation fuels while addressing growing environmental concerns.

The researchers detailed their findings in the journal Fuel Processing Technology (citation below).

The Process Behind Lignin Conversion

Lignin is a structural molecule found in plants, often derived from agricultural byproducts such as corn stover—the residual stalks, leaves, and cobs after harvesting.

The WSU team, led by Professor Bin Yang, developed a process known as simultaneous depolymerization and hydrodeoxygenation (SDHDO).

This method not only breaks down the lignin polymers but also removes oxygen atoms, producing a hydrocarbon-rich fuel suitable for aviation.

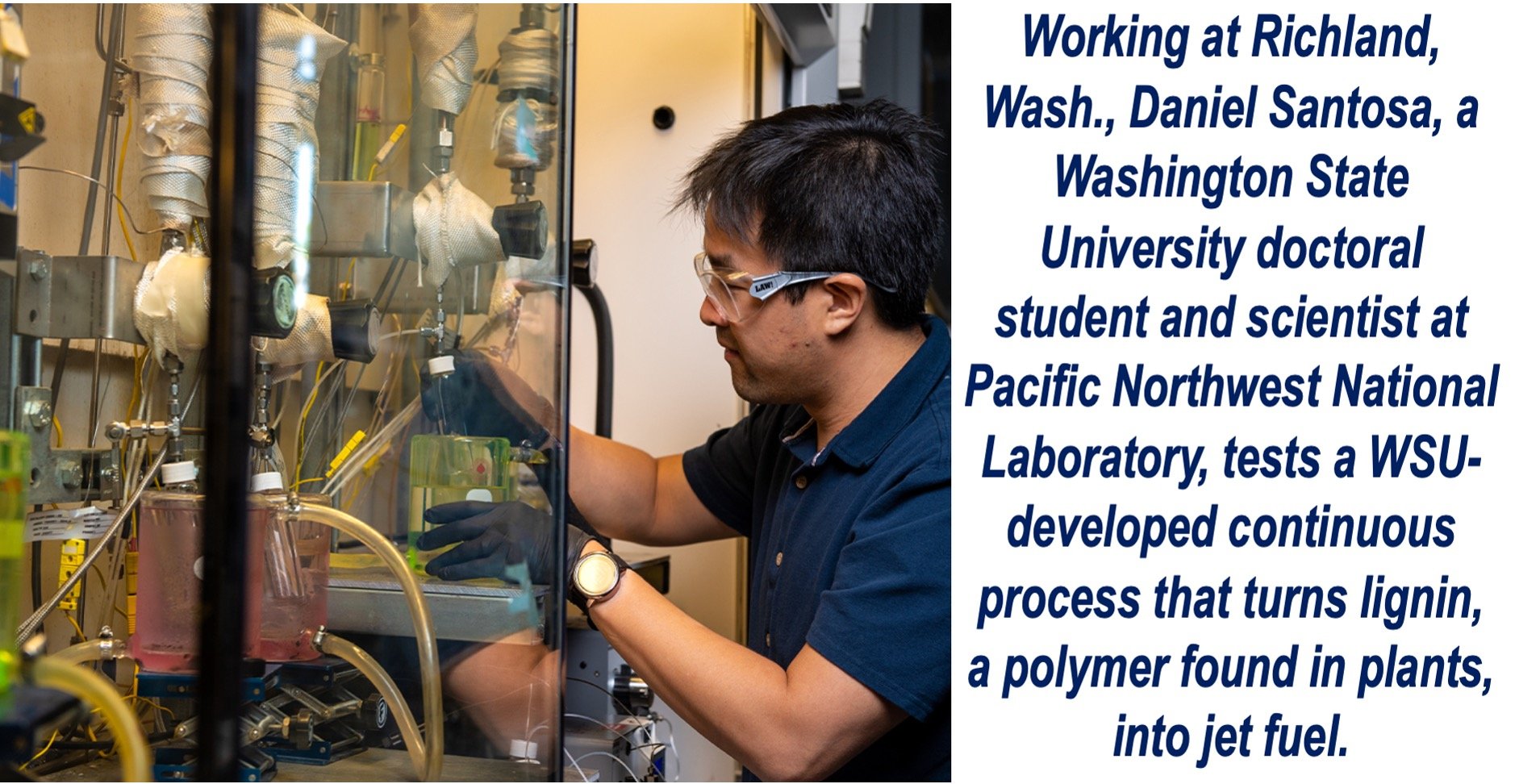

This advancement, tested in a continuous flow reactor, moves away from batch processing techniques, making it more practical for large-scale commercial application. The process involved introducing a lignin solution into a reactor, where it was treated under specific conditions to generate the desired jet fuel.

Lignin’s Role in Sustainable Aviation Fuel

Lignin-based jet fuel offers several advantages. It can serve as a cleaner alternative to fossil fuels, helping the aviation industry reduce its carbon footprint. The fuel produced from lignin has the potential to replace fossil-derived aromatics, compounds currently used in jet fuel that contribute to contrails and increased climate impacts.

The new fuel, rich in cycloalkanes, could enhance fuel performance without the harmful effects associated with traditional fossil fuels.

Moreover, the fuel’s high density and ability to swell seals in aircraft engines make it an attractive substitute for fossil fuels. This means lignin-based fuels could be used directly in current aircraft engines, with no modifications required—a characteristic known as “drop-in” capability.

Economic and Environmental Benefits

One key aspect of this research is the focus on utilizing technical lignin, a less processed and more cost-effective form of lignin. This sets it apart from other research that uses more refined lignin bio-oils, making it a promising option for large-scale production.

The benefits of lignin-based fuel extend beyond sustainability. Global aviation fuel consumption reached nearly 100 billion gallons in 2019. Experts believe demand will continue to rise over the coming decades.

Lignin-based fuels could significantly reduce aviation emissions while aligning with international goals for carbon neutrality.

Towards Commercial Viability

While the WSU team’s work marks significant progress, challenges remain in refining the process for better efficiency and cost-effectiveness. They working on improving the conversion rates of lignin and further optimizing the SDHDO process to increase the yield of usable jet fuel.

The research has garnered support from notable institutions, including the U.S. Department of Energy and the Pacific Northwest National Laboratory, highlighting its potential to make a substantial impact on the future of sustainable aviation.

Final Thoughts

The continuous conversion of lignin to jet fuel represents a promising leap toward sustainable aviation. With further improvements, lignin-based fuels could play a critical role in reducing the aviation industry’s reliance on fossil fuels, contributing to a greener, more sustainable future.

Citation

Kumar, A., Bell, D. C., Yang, Z., Heyne, J., Santosa, D. M., Wang, H., Zuo, P., Wang, C., Mittal, A., Klein, D. P., Manto, M. J., Chen, X., & Yang, B. (2024). A simultaneous depolymerization and hydrodeoxygenation process to produce lignin-based jet fuel in continuous flow reactor. Fuel Processing Technology, 263, 108129. https://doi.org/10.1016/j.fuproc.2024.108129