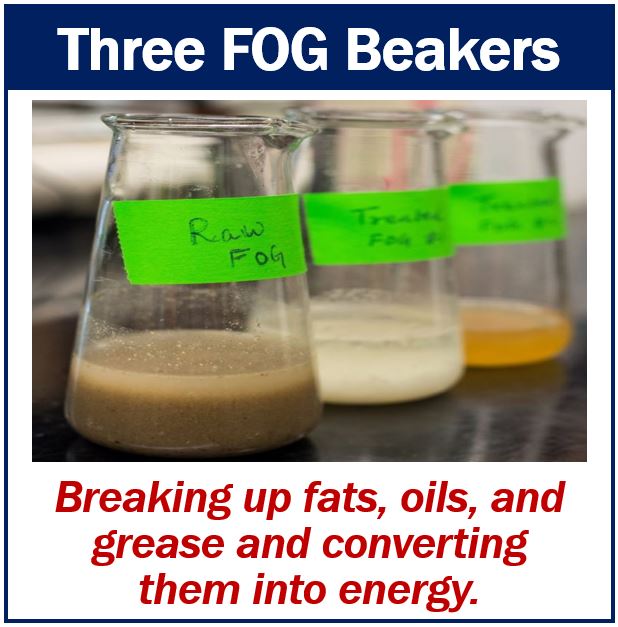

Fats, oils, and grease, i.e., FOG, can clog up pipes. Recently, they blocked London’s sewage system. They can also harm fish and grow into ‘fatbergs.’ Fatbergs are congealed lumps in a sewer system that consist of wet wipes, grease, and other non-biodegradable solid matter.

Researchers at the University of British Columbia say they have found a way of treating FOG and turning it into energy.

Asha Srinivasan and colleagues wrote about their study and findings in the journal Water, Air & Soil Pollution (citation below). Dr. Srinivasan, a Research Associate, has been working at the Department of Civil Engineering, University of British Columbia, since 2012.

Treating FOG

In this study, the researchers heated samples of fats, oils, and grease to temperatures between 90℃ and 110℃. They also added hydrogen peroxide. Hydrogen peroxide or H2O2 kickstarts the breakdown of organic matter.

The authors said that the treatment reduced the volumes of solids in the fats, oils, and grease significantly. In fact, by as much as 80%. With this treatment, the mixture also released fatty acids.

Bacteria can break down the fatty acids in the next stage of treatment.

Microorganisms feed on it

Dr. Srinivasan said:

“FOG is a terrific source of organic material that microorganisms can feed on to produce methane gas, which is a valuable, renewable energy source. But if it’s too rich in organics, bacteria can’t handle it, and the process breaks down.”

“By preheating it to the right temperature, we ensure that the FOG is ready for the final treatment and can make the maximum amount of methane.”

If farmers adopt the methods the researchers developed, they will be able to load more FOG into their biogas digesters.

Biogas digesters are large tanks that convert organic waste into methane gas. Bacteria in the biogas digesters, through a process of anaerobic digestion, convert the waste into methane.

Farmers use biogas digesters to treat farm waste, including manure, to produce methane.

Methane or CH4 is a common fuel source. It is the main component of natural gas.

Farmer can use more FOG

Dr. Srinivasan explained:

“Farmers typically restrict FOG to less than 30 percent of the overall feed. But now the FOG can be broken down into simpler forms, so you can use much more than that, up to 75 percent of the overall feed. You would recycle more oil waste and produce more methane at the same time.”

Lead research, Victor Lo, said that we could ultimately use the technology in municipal FOG management programs.

Lo, Emeritus Professor of Civil Engineering at the University of Columbia said:

“The principle would be the same: you could pretreat the FOG, so it doesn’t clog the pipes, and add it to sewage sludge to produce methane from the mix.”

The authors believe that the treatment they developed had never been used or studied before. Simple methods do exist, however, to break down fats, oil, and grease.

They are hoping to carry out more research to determine the optimal ratio of FOG to dairy manure. Then, they could be pretreated together.

Citation:

‘Microwave-Enhanced Advanced Oxidation Treatment of Lipids and Food Wastes,’ Asha Srinivasan, Moutoshi Saha, Kit Caufield, Otman Abida, Ping Huang Liao, Kwang Victor Lo. Water, Air, & Soil Pollution, July 2018, 229:227. DOI: https://doi.org/10.1007/s11270-018-3894-y. Publisher: Springer International Publishing. Print ISSN: 0049-697. Online ISSN: 1573-2932.