Imagine a clothing material that cools the human body so that our demand for air conditioning is reduced considerably during those summer months. A low-cost plastic material that could significantly help reduce our contribution to global warming has been developed by a team of engineers at Stanford University.

Yi Cui, an associate professor of materials science and engineering at Stanford and of photon science at SLAC National Accelerator Laboratory, and colleagues explained in the journal Science how they developed a low-cost, plastic-based textile which they believe could be woven into clothing material.

This new clothing material would cool your body considerably more efficiently than is currently possible with the natural or synthetic fabrics in today’s garments.

The new material satisfied the scientists’ three requirements simultaneously: 1. Infrared radiation transparency – heat passes right through it. Visible light opacity – it is not transparent. 2. Air convection – water vapour passes through it and evaporates in the air. (Image: science.sciencemag.org)

The new material satisfied the scientists’ three requirements simultaneously: 1. Infrared radiation transparency – heat passes right through it. Visible light opacity – it is not transparent. 2. Air convection – water vapour passes through it and evaporates in the air. (Image: science.sciencemag.org)

Clothing material that keeps us cool

Imagine a new family of fabrics which could one day become the basis for garments that keep humans cool in hot climates without any need for energy-hungry air conditioning, they wrote. Rather than having to cool the building, which consumes a lot of energy, the person is cooled instead.

Prof. Cui said:

“If you can cool the person rather than the building where they work or live, that will save energy.”

This revolutionary material allows the human body to release heat in two ways that would make the wearer feel considerably cooler – a cool 2.7°C 3.6°F – than if he or she wore cotton clothing.

This material allows perspiration to evaporate through it, something that that already occurs with ordinary fabrics. However, it also provides a second, revolutionary cooling mechanism – it allows the heat that our bodies emit as infrared radiation to pass right through it.

Stanford scientists started with a sheet of polyethylene and modified it with a series of chemical treatments, resulting in a cooling fabric. (Image: news.stanford.edu. Credit: L.A. Cicero)

Stanford scientists started with a sheet of polyethylene and modified it with a series of chemical treatments, resulting in a cooling fabric. (Image: news.stanford.edu. Credit: L.A. Cicero)

The human body, like those of animals and all other objects, throw off heat in the form of infrared radiation or thermal radiation, invisible and benign radiant energy with longer wavelengths than those of visible light.

Blankets keep us warm by trapping the infrared heat emissions close to the human body. When we wear night-vision goggles, we can see other humans and animals; they can detect this thermal radiation that escapes the body.

Shanhui Fan, who works at the Stanford *Photonics Research Centre and specializes in photonic crystals, computational electromagnetics and optical communications, said:

“Forty to 60 percent of our body heat is dissipated as infrared radiation when we are sitting in an office. But until now there has been little or no research on designing the thermal radiation characteristics of textiles.”

* Photonics is the science of photon (light) generation, detection, manipulation through emission, transmission, modulation, detection/sensing, and signal processing.

Ultra-powered kitchen wrap

To develop this new cooling textile, the scientists blended photonics, nanotechnology and chemistry to give polyethylene – the clear, stretchable, clingy plastic we use as kitchen wrap (UK: cling film) – a number of features desirable in clothing material: 1. It allows water vapour, air to pass through it. 2. Thermal radiation passes right through it. 3. It is not see-through – it is opaque to visible light.

The easiest feature was allowing infrared radiation to pass through the plastic material, because this characteristic already exists in ordinary kitchen food wrap.

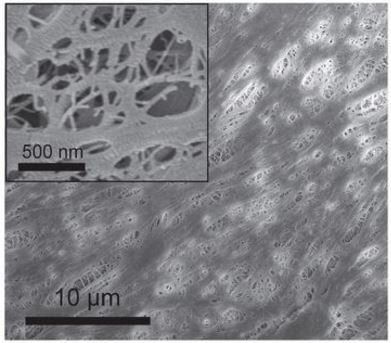

High-resolution SEM images of the new material. The nanopores are only 50 to 1000 nm in diameter, which is essential to ensure high IR transmittance. (Image: science.sciencemag.org)

High-resolution SEM images of the new material. The nanopores are only 50 to 1000 nm in diameter, which is essential to ensure high IR transmittance. (Image: science.sciencemag.org)

Kitchen wrap, however, is impermeable (water can’t pass through it) and is also see-through, rendering it useless as clothing. Nobody, except the most daring among us, would consider wearing completely see-through clothing.

Prof. Cui and colleagues tackled these challenges one at a time.

They first found a variant of polyethylene that is commonly used in battery making that has a specific nanostructure that is opaque (not see-through) to visible light yet transparent to infrared radiation, which means that it lets body heat escape through it.

This provided a material that we cannot see through, thus addressing our aversion to walking around seemingly naked in public, but thermally transparent for purposes of energy efficiency.

They then treated the industrial polyethylene with benign chemicals so that water vapour molecules could evaporate through nanopores – microscopic holes – in the plastic. According to co-author Po-Chun Hsu, a postdoctoral scholar, this allowed the plastic to breathe like a natural fibre.

Making clothing material

The scientists now had a single-sheet material that met their three basic criteria for a cooling textile:

1. Air (water vapour) can pass through it.

2. Heat goes through it.

3. It is opaque – it is not transparent.

To make this very thin material more like the fabrics in our garments, they created a three-ply version: two sheets of treated polyethylene separated by a cotton mesh for thickness and strength.

They now needed to test the cooling potential of their three-ply construct against a cotton fabric of comparable thickness. They placed an equal swatch of each material on a surface that had the same temperature as bare human skin, and measured how much heat each material insulated (trapped).

Prof. Fan said:

“Wearing anything traps some heat and makes the skin warmer. If dissipating thermal radiation were our only concern, then it would be best to wear nothing.”

They found that the cotton fabric made the skin surface 2.7°C or 3.6°F warmer than their new textile. The authors said this difference means that a human being dressed in their new material would be less likely to turn on the air conditioner or a fan.

The scientists say that their research is ongoing. They plan to add more colours and textures to their new material, as well as finding ways of giving it more cloth-like characteristics.

Adapting a material that we already mass produce for the battery industry would make it easier to create products in large quantities.

“If you want to make a textile, you have to be able to make huge volumes inexpensively,” Prof. Cui said.

Prof. Fan says their research has opened up new avenues of inquiry to heat or cool things, passively – without having to use outside energy. Materials could be tuned to trap or dissipate infrared radiation.

Prof. Fan said:

“In hindsight, some of what we’ve done looks very simple, but it’s because few have really been looking at engineering the radiation characteristics of textiles.”

In an Abstract describing the main paper in the journal, the authors wrote:

“We developed a device to simulate skin temperature that shows temperatures 2.7° and 2.0°C lower when covered with nanoPE cloth and with processed nanoPE cloth, respectively, than when covered with cotton. Our processed nanoPE is an effective and scalable textile for personal thermal management.”

Citation: “Radiative human body cooling by nanoporous polyethylene textile,” Po-Chun Hsu, Alex Y. Song, Peter B. Catrysse, Chong Liu, Yucan Peng, Jin Xie1, Shanhui Fan & Yi Cui. Science. 2 September 2016. Vol. 353, Issue 6303, pp. 1019-1023. DOI: 10.1126/science.aaf5471.

Video – Plastic textile that dissipates heat

This Stanford University video explains how scientists have engineered a cheap plastic material that could be used for making clothing material that cools the human body, which would significantly reduce the need for energy-wasting air conditioning.

Comments are closed.