Dry Ice Blasting (or CO2 blasting) can be an incredibly effective and cost-efficient cleaning method for the right application. Mid Valley uses the latest technologies to clean with dense CO2 pellets without damaging material (surfaces).

Because of the temperature difference between the dry ice particles (-109° F) and the surface being treated, thermal shock occurs, breaking down the bond between the material and contaminant. And since dry ice sublimates on impact, no waste stream is created. A number of industries worldwide have discovered the advantages of this precision cleaning process.

A little known fact about dry ice blasting is that, in many cases, it has been determined to completely clean, sanitize, and decontaminate surfaces by killing Salmonella, E. coli, and Listeria, making it an excellent alternative to risky or inefficient traditional types of cleaning in the food & food packaging industry.

Dry Ice Blasting Affects Various Areas All Around the World . Dry Ice Blasting in Michigan Also affects very hardly. Blasting equipment that is used in Michigan is an OEM of dry ice blasting equipment that offers a more effective alternative cleaning solution to methods such as sand, soda, and abrasive blasting. Our dry ice blasting machines feature unparalleled technology and can be used in a variety of industries and applications. Many equipment offer a range of purchasing options for dry ice blasting equipment whether you’re looking to lease, purchase new, or purchase used machines.

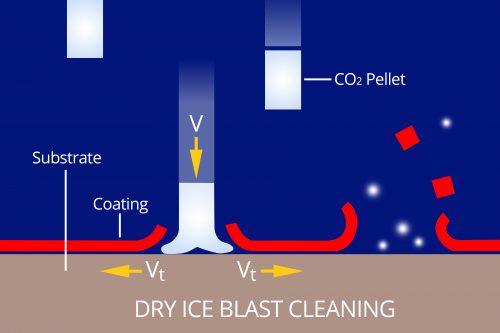

Dry ice blasting, also known as carbon dioxide or CO2 cleaning is where dry ice, in a solid pellet form, is accelerated through a hose with pressurized air and aimed at a solid surface to clean.

The cleaning method is similar to other types of media blasting such as sand blasting, plastic bead blasting, or soda blasting. Dry ice blasting uses dry ice pellets as the blasting medium. Dry ice blasting is non abrasive, non-conductive, nonflammable, and non-toxic.

Dry ice blasting equipment propels the pellets at extremely high speeds. Upon impact, the pellet sublimates, transferring minimal kinetic energy to the surface of substrate on impact producing minimal abrasion. The sublimation process causes a micro-thermal shock between the surface contaminate and the substrate. The substrate, which is warmer, causes the dry ice to convert back into a harmless CO2 gas. The gas expands to nearly 800 times the volume of the original pellet and the surface contaminate is lifted by the CO2 from behind, falling away from the surface. Since the dry ice has now evaporated (CO2 gas), the only clean up that remains, with our highly-effective dry ice cleaning solution, is the contaminate.

Dry ice blasting is an environmentally responsible cleaning process. Dry ice is made of reclaimed carbon dioxide that is produced from other industrial processes, does not add additional greenhouse gases to the atmosphere. Dry ice blasting is approved by the EPA, FDA and USDA. It also eliminates employee exposure to chemical cleaning agents and solvents.

Dry ice blasting does not create secondary waste or chemical residues. Dry ice sublimates, or turns back into a gas when it hits the surface that is being cleaned. With dry ice blasting there is no clean-up of a blasting medium and the contaminate that has fallen from the surface can be swept up, vacuumed or washed away. Traditional cleaning methods contribute thousands of tons of toxic secondary waste to our landfills each year. Dry ice blasting eliminates the secondary waste by simply disappearing upon impact.

Interesting Related Article: “4 Reasons Deep Cleaning Is Important During COVID-19“